Photoelectric vehicle height sensor

A sensor and photoelectric technology, applied in the field of auto parts, can solve problems such as poor operation stability and reduced comfort, and achieve the effect of maintaining basically unchanged and improving anti-pitching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

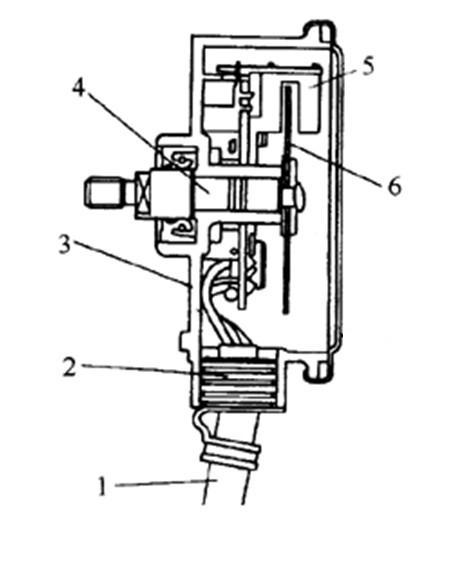

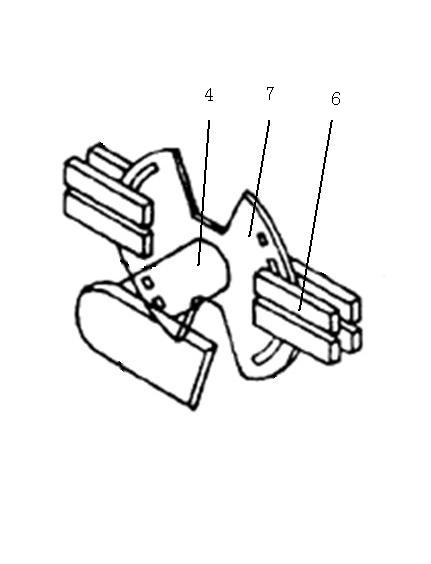

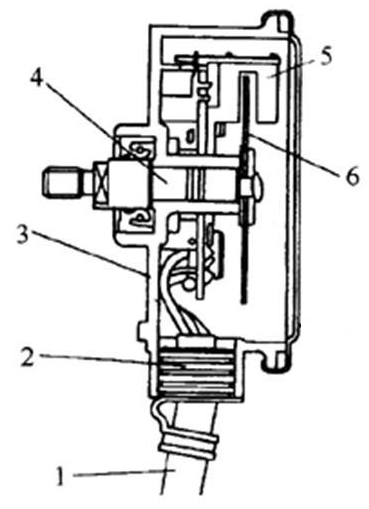

[0011] Such as figure 1 , 2 As shown, the present invention includes a wiring cable 1, a housing 3, a shaft 4, a photoelectric coupling element 5, and a shading disc 6. The wiring cable 1 is installed at the bottom of the housing 3, and the wiring cable 1 and the housing 3 are provided Oil seal 2. The wiring cable 1 is connected to a photoelectric coupling element 5 installed inside a housing 3, the housing 3 is equipped with a shaft 4, the shaft 4 is sleeved in the photoelectric coupling element 5, and the shaft 4 is installed There are a disc 7 and a shading disc 6. The shading disc 6 is composed of a light emitting diode and a photosensitive triode. One end of the shading disc 6 is located in the groove of the photoelectric coupling element 5, and the disc 7 is located in the shading disc 6, so There are multiple narrow grooves on the edge of the disc 7. The rotation of the disc 7 can switch the output of the shutter disc 6 to ON and OFF, and the ON and OFF conversion signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com