Irradiation device

A light irradiation device and light source technology, which is applied to lighting devices, components of lighting devices, optics, etc., can solve the problems of excimer lamp shaking, lamp damage, and damage to the uniformity of illumination of the light irradiation surface, and achieve in-plane uniformity High, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] Hereinafter, embodiments of the present invention will be described in detail.

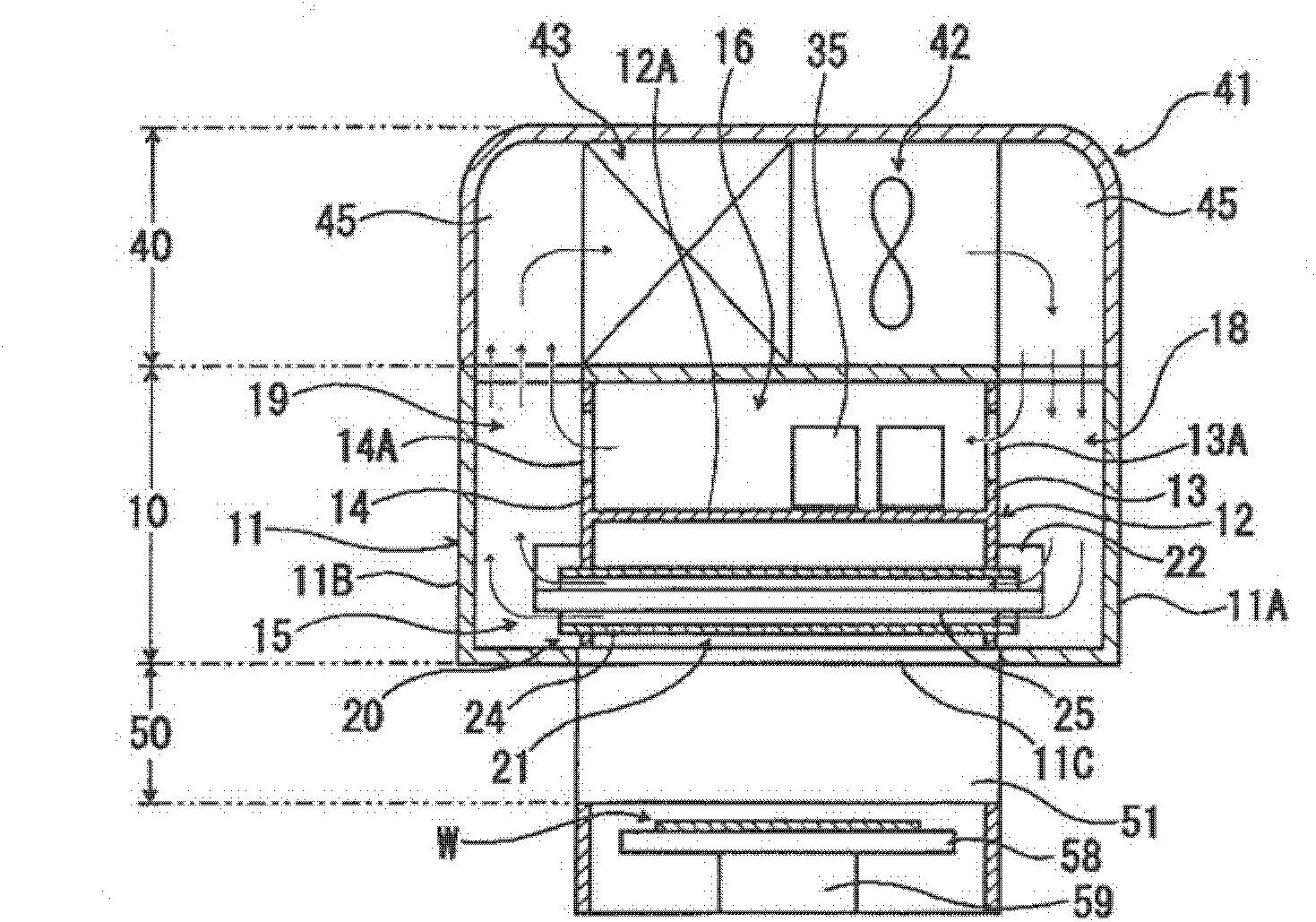

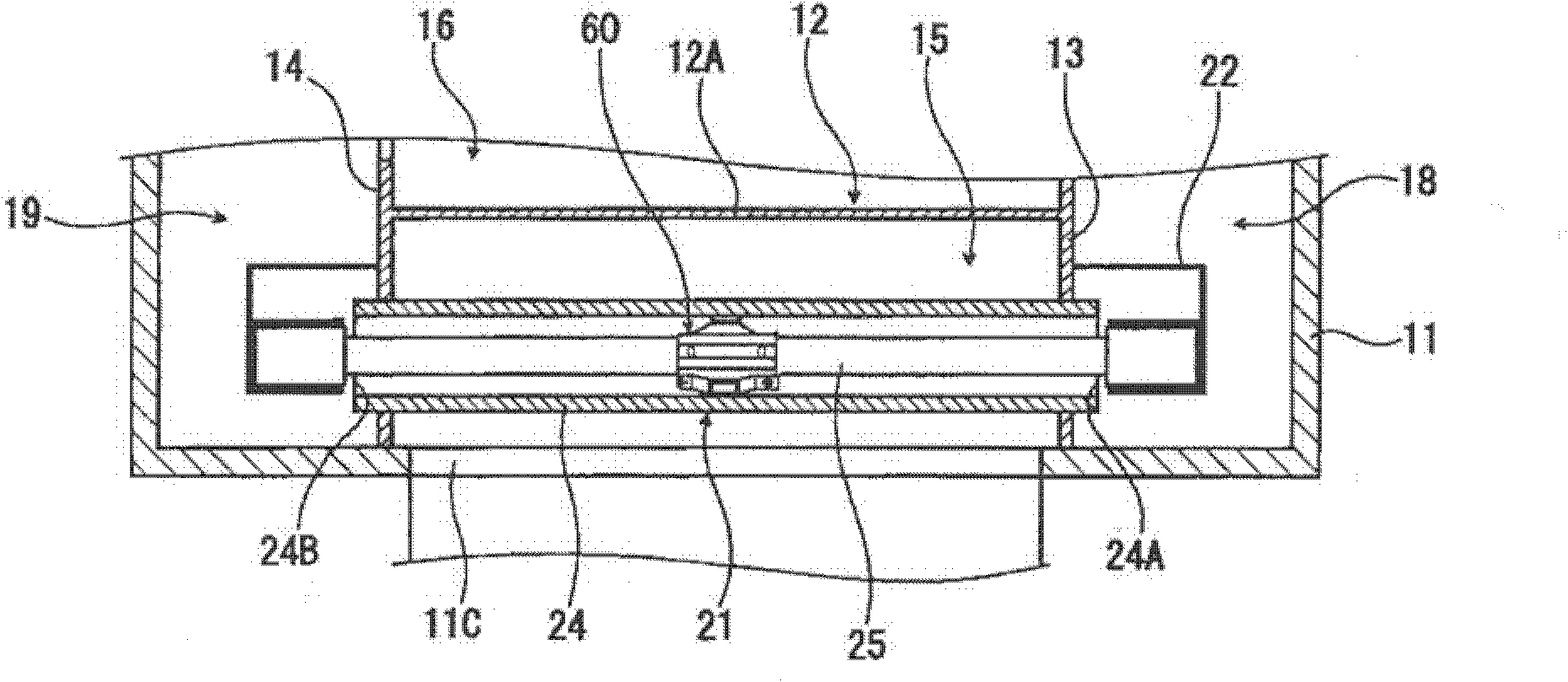

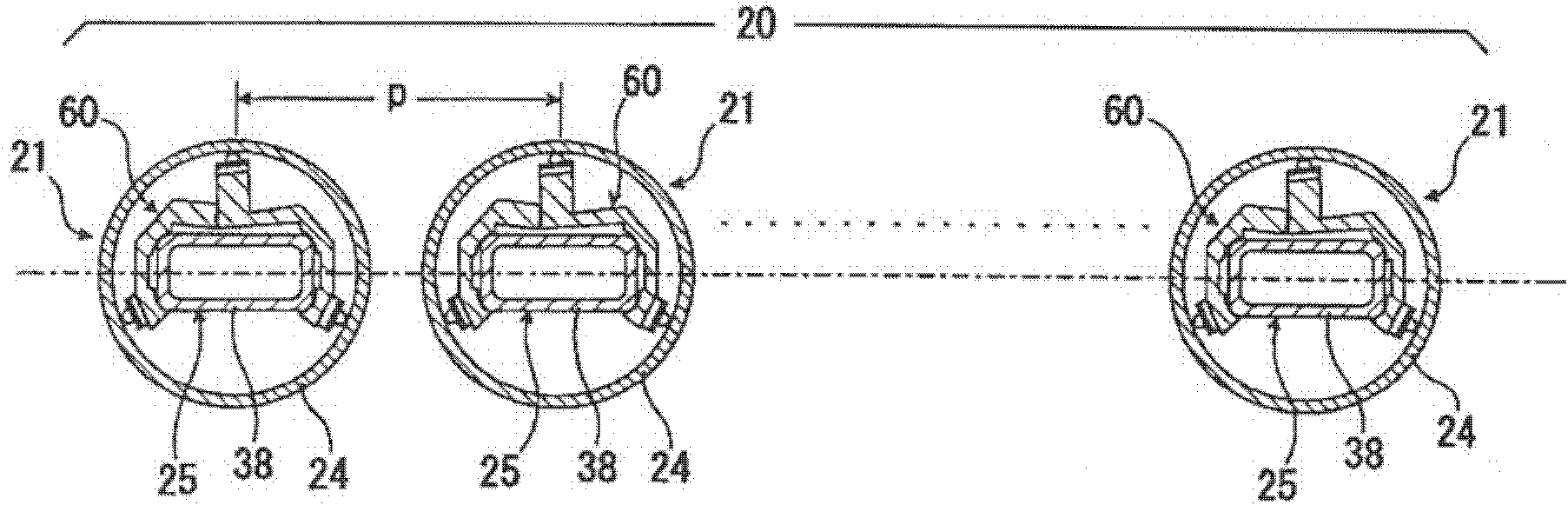

[0107] figure 1 It is an explanatory diagram showing the outline of the internal structure of one configuration example of the ultraviolet irradiation device of the present invention, figure 2 is enlarged figure 1 A cross-sectional view of a part of the UV irradiation device shown.

[0108] This ultraviolet irradiation device is basically constituted by a light source unit 10, a cooling unit 40, a light guide unit 50, and a power supply unit (not shown).

[0109] The light source unit 10 includes a light source unit case member 11 having a light irradiation opening 11C opened downward and having a box-like shape as a whole.

[0110] Inside the light source case member 11, a frame body 12 with a cross-sectional shape of approximately H shape is provided, and the frame body 12 is formed by a planar partition wall 12A extending in the horizontal direction, and the light source part case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com