Mixed palletizing production line device and palletizing system

A production line and mixed code technology, applied in the direction of conveyor control devices, object stacking, object destacking, etc., can solve the problems of empty pallets that cannot be discarded, large loss of plastic pallets, pallet collision and extrusion, etc., and achieve the reduction of equipment The effect of placing space, saving purchase cost, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

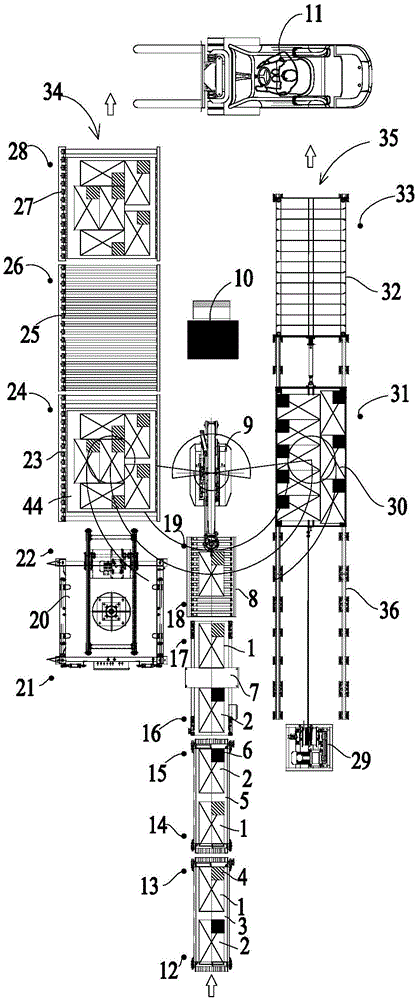

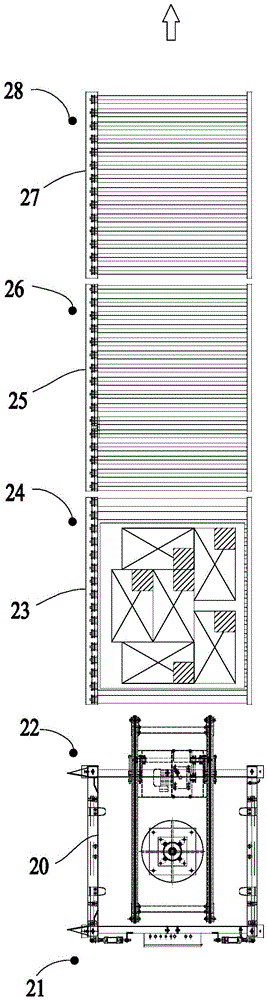

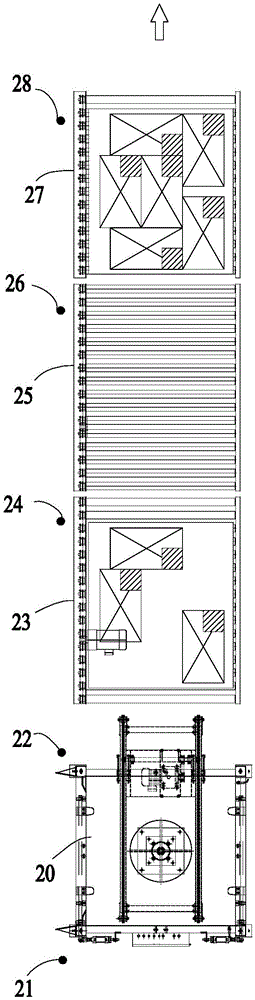

[0037] Such as figure 1 Shown: In order to process two kinds of material packaging bags of different specifications on one incoming material conveying channel and reduce the production cost, the present invention includes a slow-stop conveyor for receiving the incoming material and conveying the incoming material forward; One end of the stop conveyor is provided with a re-inspection scale detection unit 7, and the re-inspection scale detection unit 7 is positioned at the forward direction that the slow-stop conveyor will convey the material, and the front end of the re-examination scale detection unit 7 is provided with a grab bag position conveyor 8, The front end of the bag-grabbing position conveyor 8 is provided with a palletizer main frame 9, and both sides of the palletizer main frame 9 are provided with a first pallet conveying line 34 and a second palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com