Spring unit for a damper and related damper

A technology of spring unit and shock absorber, which is applied in the direction of shock absorber, spring/shock absorber, spring, etc., can solve the problem that spring rigidity cannot be adjusted, and achieve the effect of simple composition, simplified formation process, and simplified geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

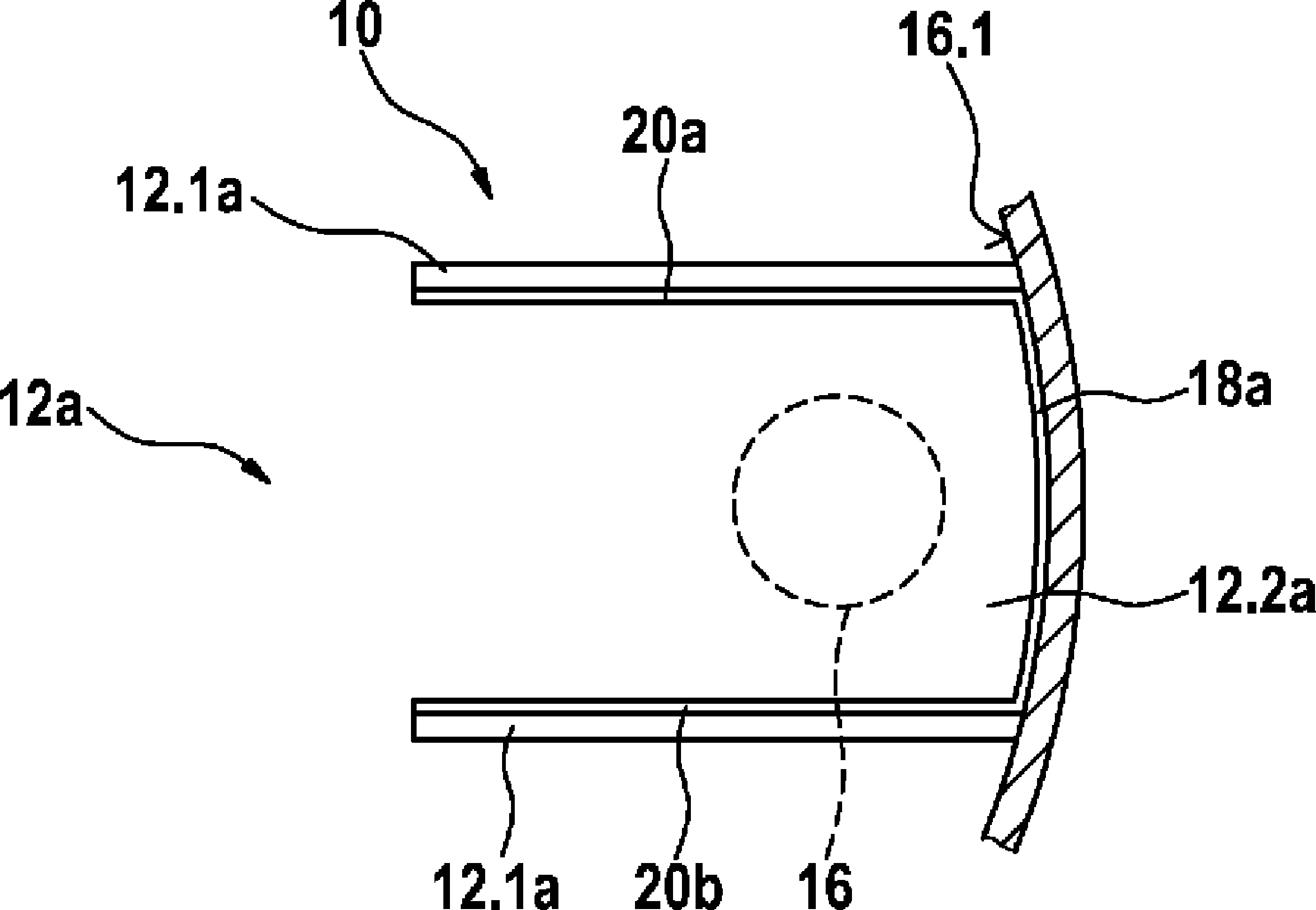

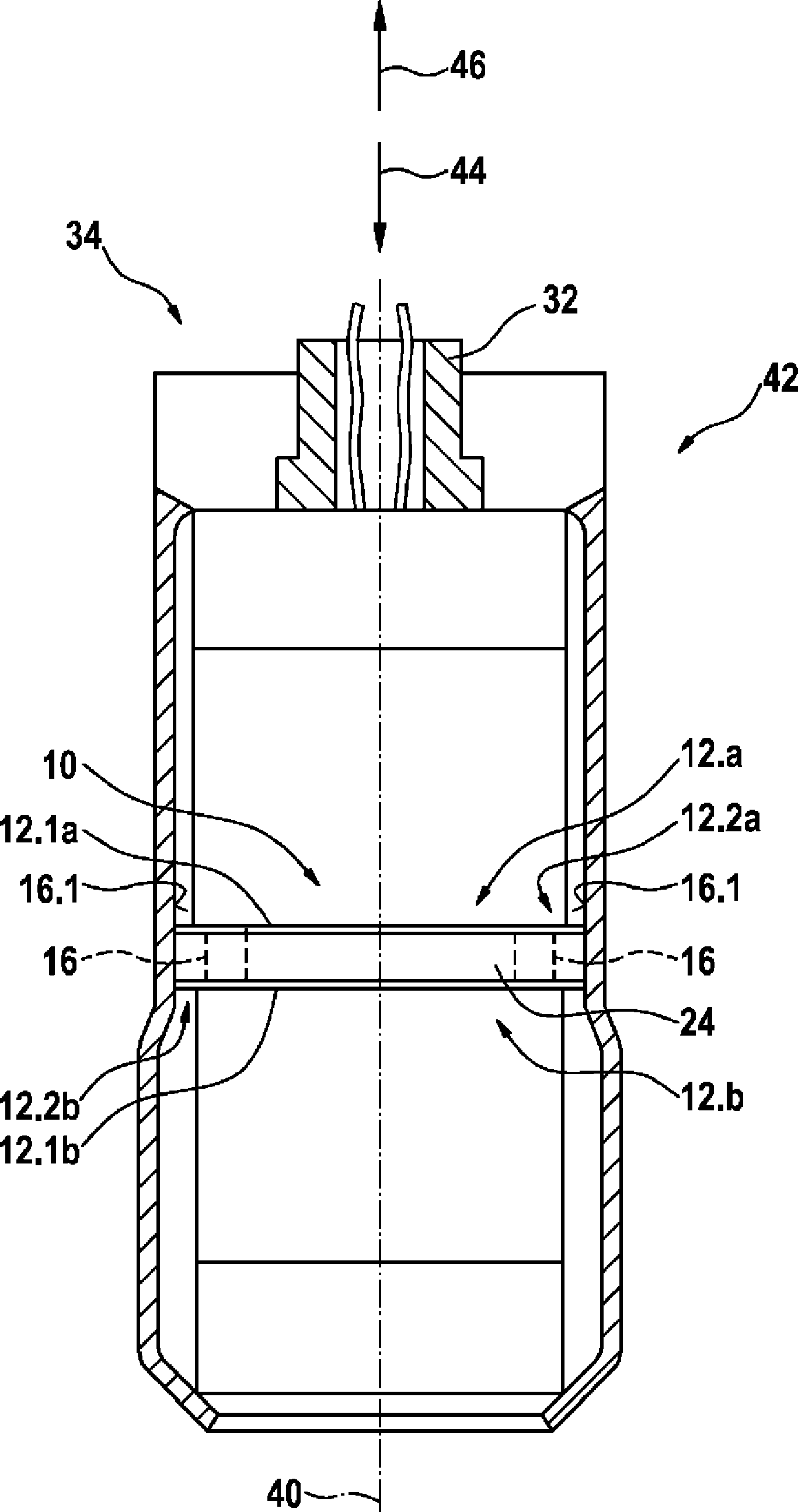

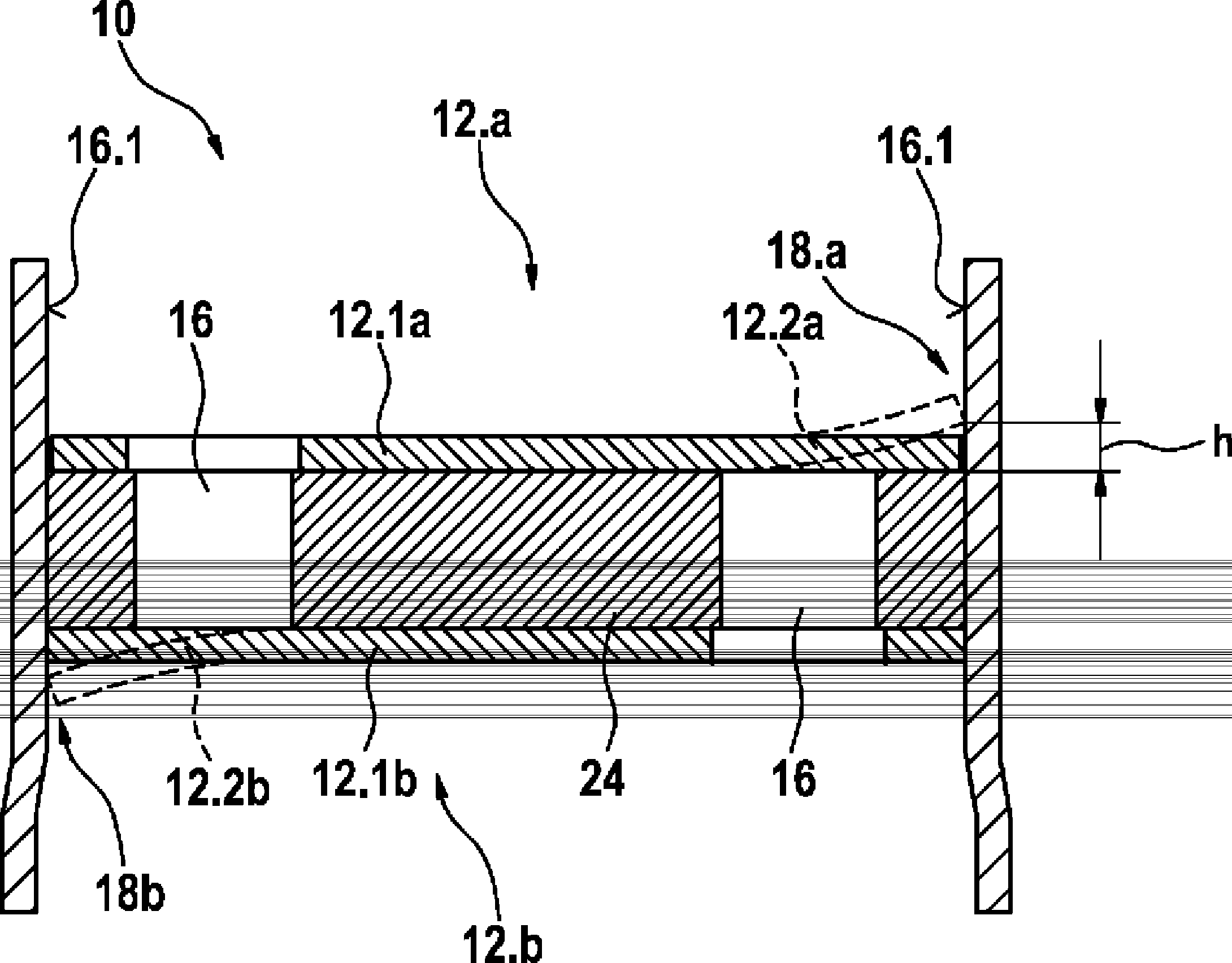

[0018] as available from figure 1 As seen in the figure, the shock absorber 26, which is preferably configured as a shock absorber for a vehicle according to the present invention, includes a shock absorber cylinder 28 filled with the shock absorber fluid 14, in which the shock absorber cylinder 28 can move A piston unit 30 is arranged in a manner that includes a piston rod 32 and a piston plunger 34 , wherein the piston plunger 34 is guided in the shock absorber cylinder 28 via the piston rod 32 . The piston punch 34 divides the shock absorber cylinder 28 into an upper shock absorber chamber 36 and a lower shock absorber chamber 38 . During the axial movement of the piston rod 32 and thus the piston punch 34 relative to the shock absorber cylinder 28, preferably in the direction of the vertical axis 40 of the shock absorber 26, the shock absorber fluid 14 must pass through the The flow through device 42 inside the shock absorber cylinder 28 to flow, the flow through device 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com