Four-axle automobile chassis and automobile crane with same

A technology for automobile chassis and axles, which is applied to steering mechanisms, vehicle parts, fluid steering mechanisms, etc. It can solve problems that affect the efficiency of lifting operations, insufficient front axle load, and large rear axle load, so as to improve the operating efficiency of the whole machine. Avoid cumbersomeness and the effect of improving time and carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

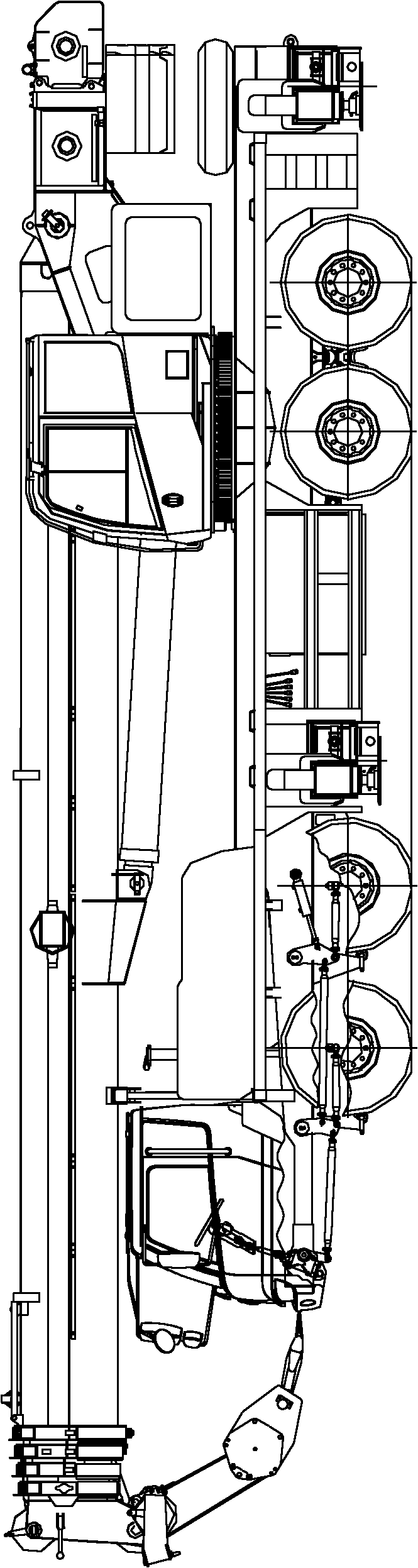

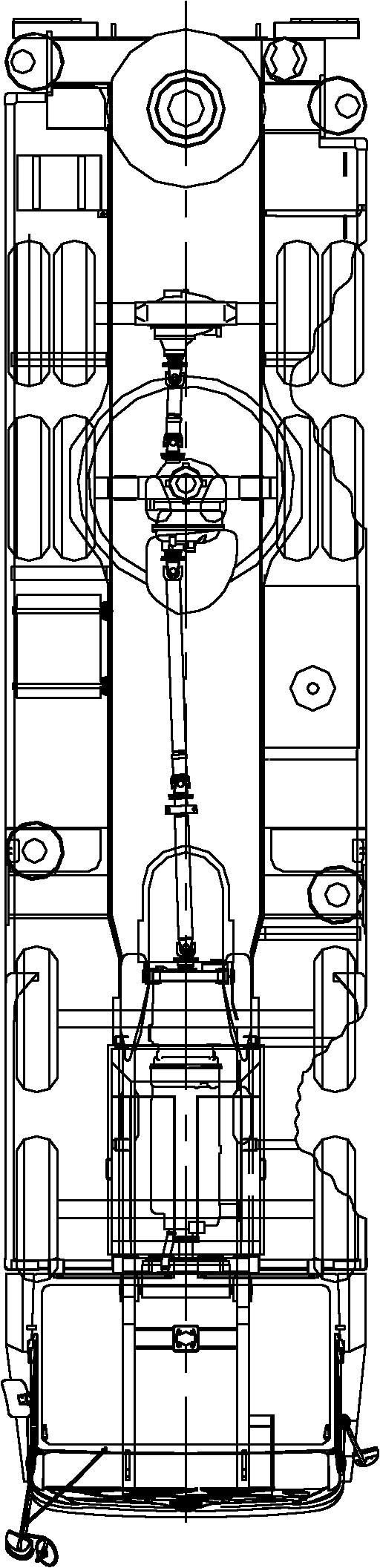

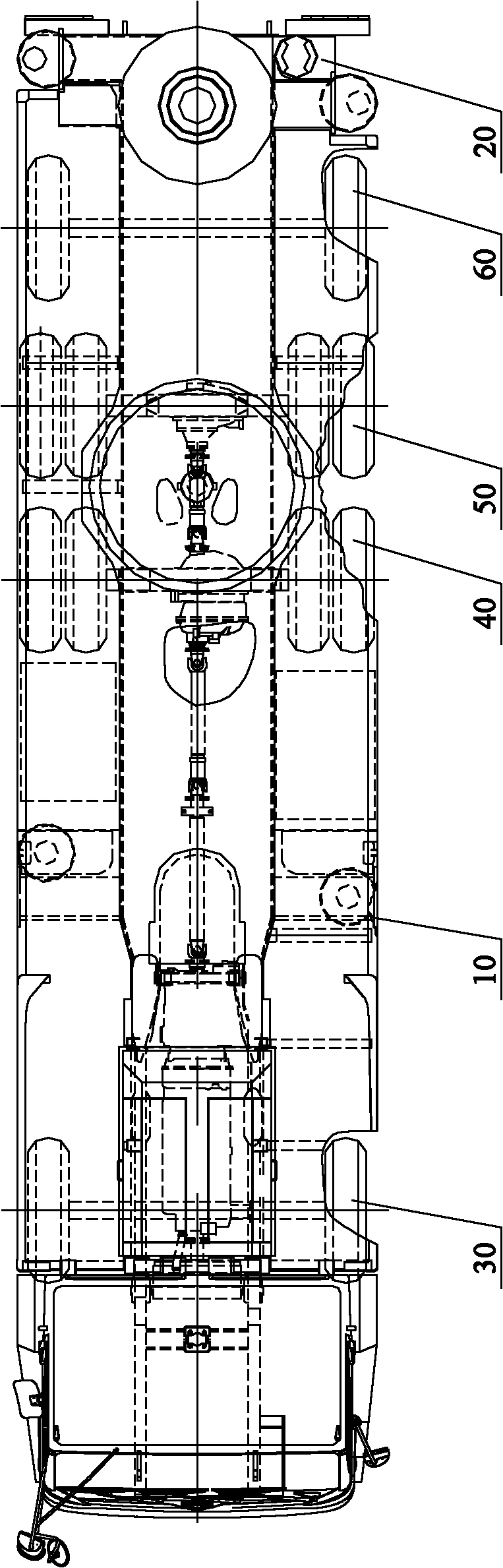

[0037] The core of the present invention is to provide a four-axle automobile chassis applicable to various types of wheeled construction machinery. The chassis can realize the effective balance of the working load of each axle through structural optimization, and improve the bearing capacity of the four-axle automobile chassis. On this basis, the efficiency of transition operations can be further improved. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0038] Without loss of generality, this embodiment will take a four-axle truck crane as the main body for detailed description.

[0039] Same as the prior art, the truck crane has functional components such as a four-axle truck chassis and a boarding actuator arranged on the chassis frame, for example, a boom device hinged at the front of the frame for controlling the hook, The hoisting device for downward displacement, the luffing mechanism for adjusting the attitude of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com