Patents

Literature

38results about How to "Reduce the chance of a flat tire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

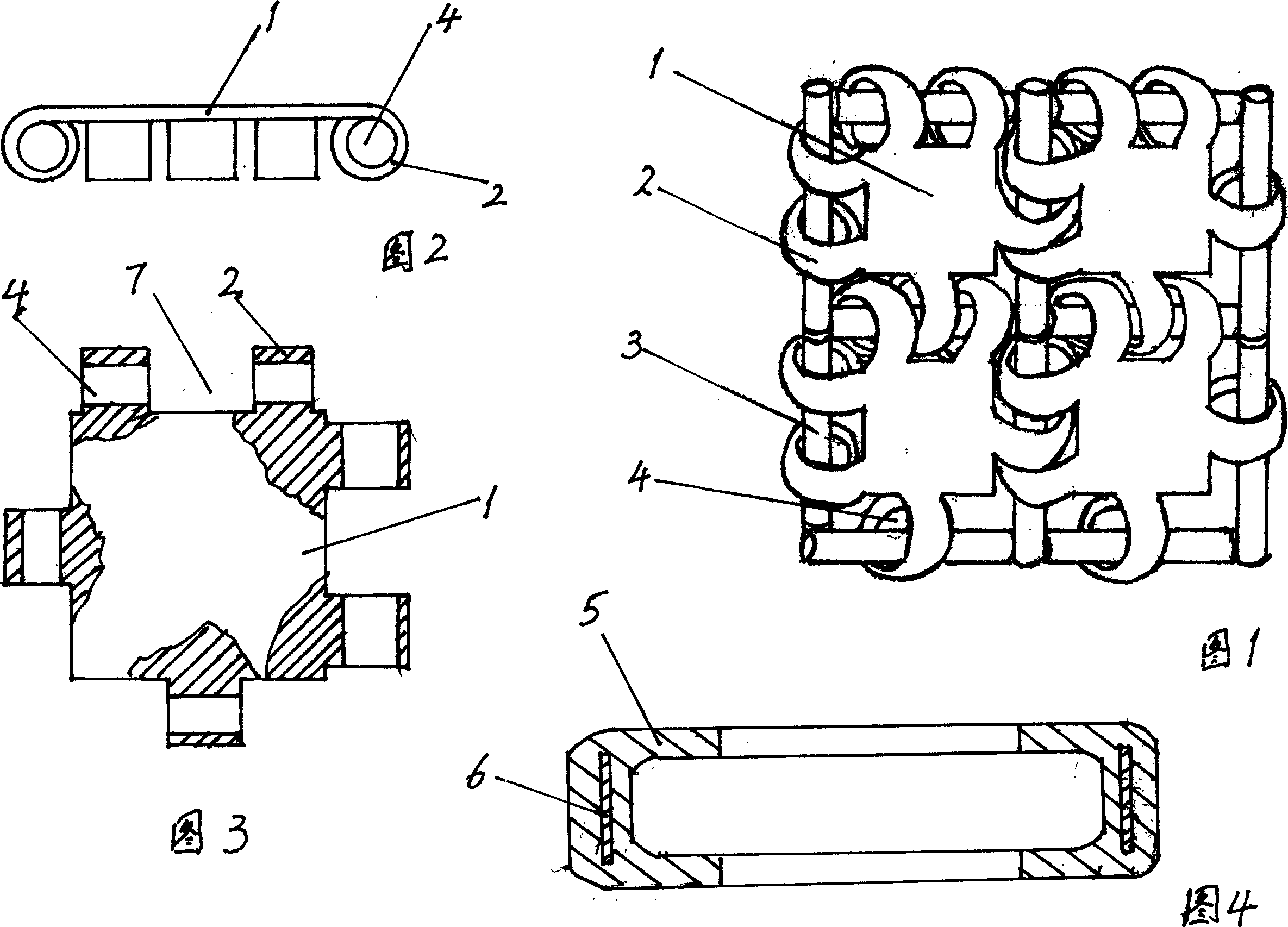

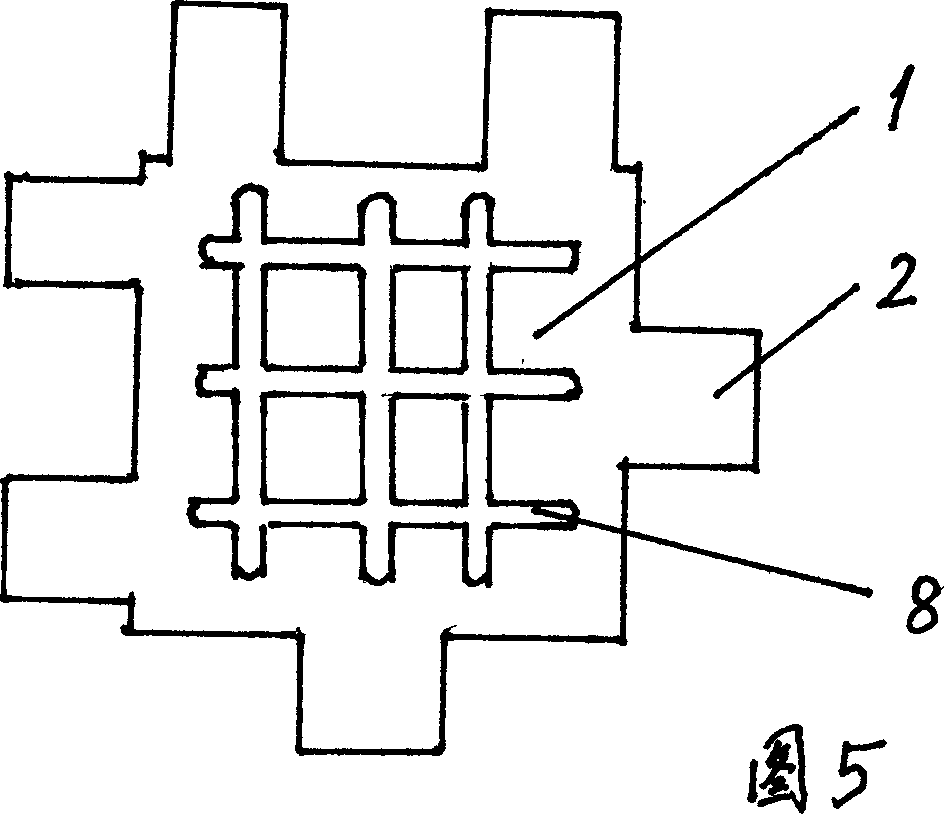

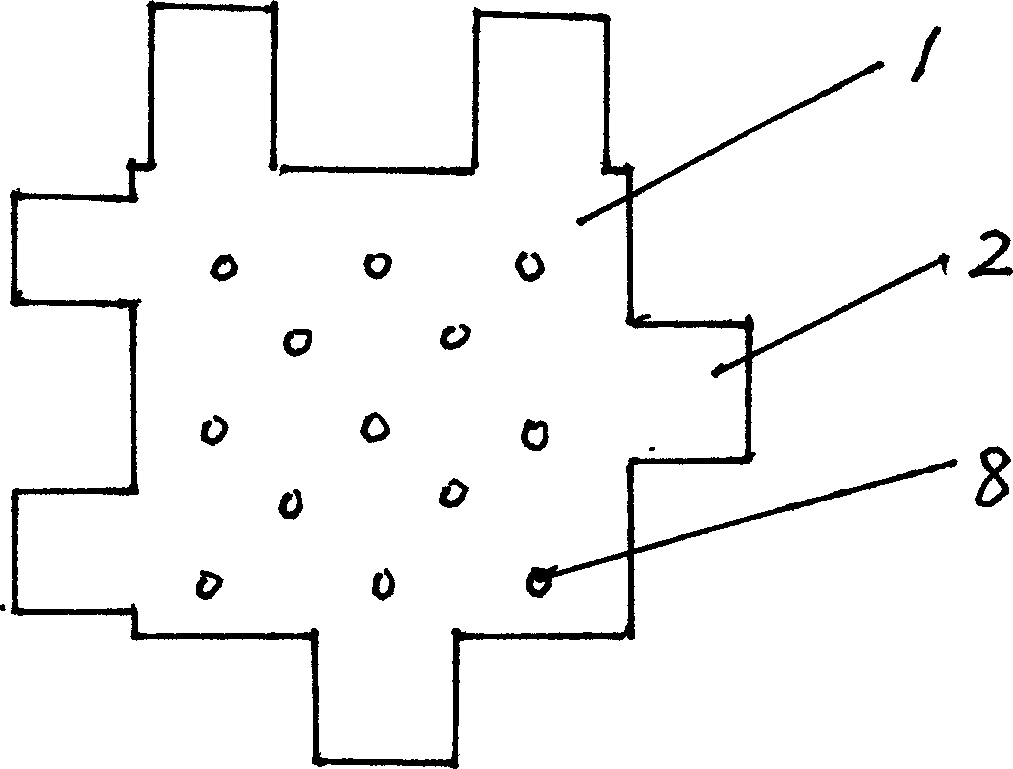

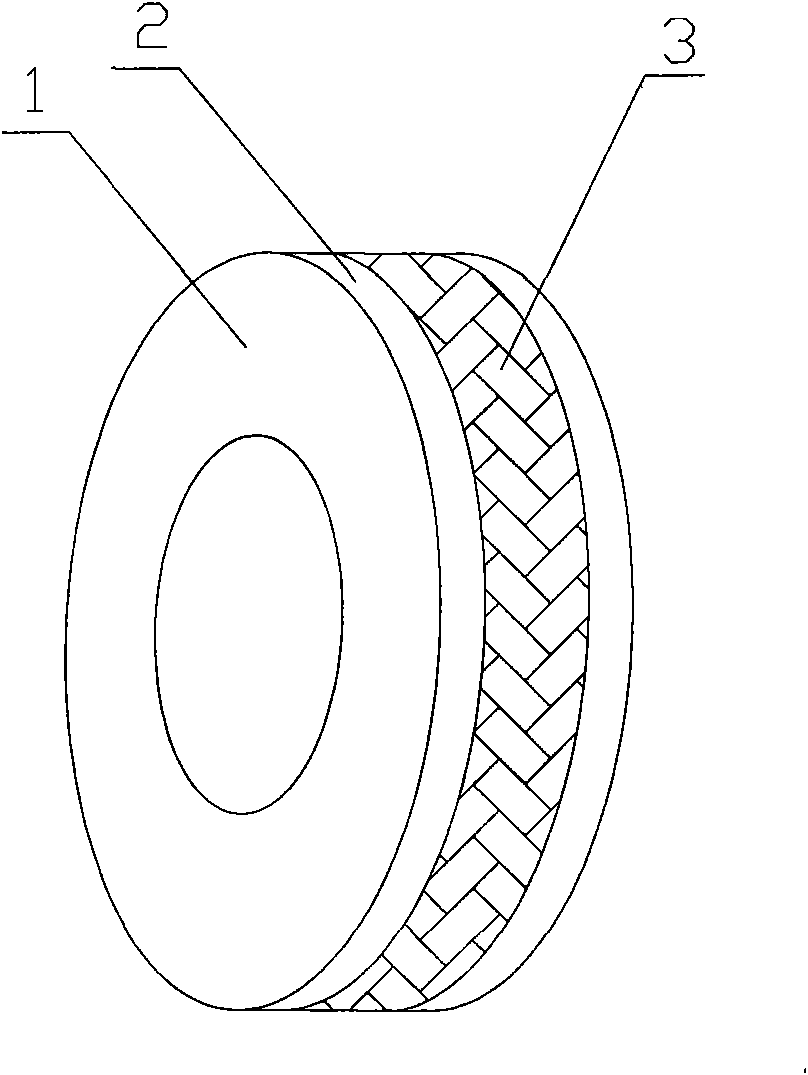

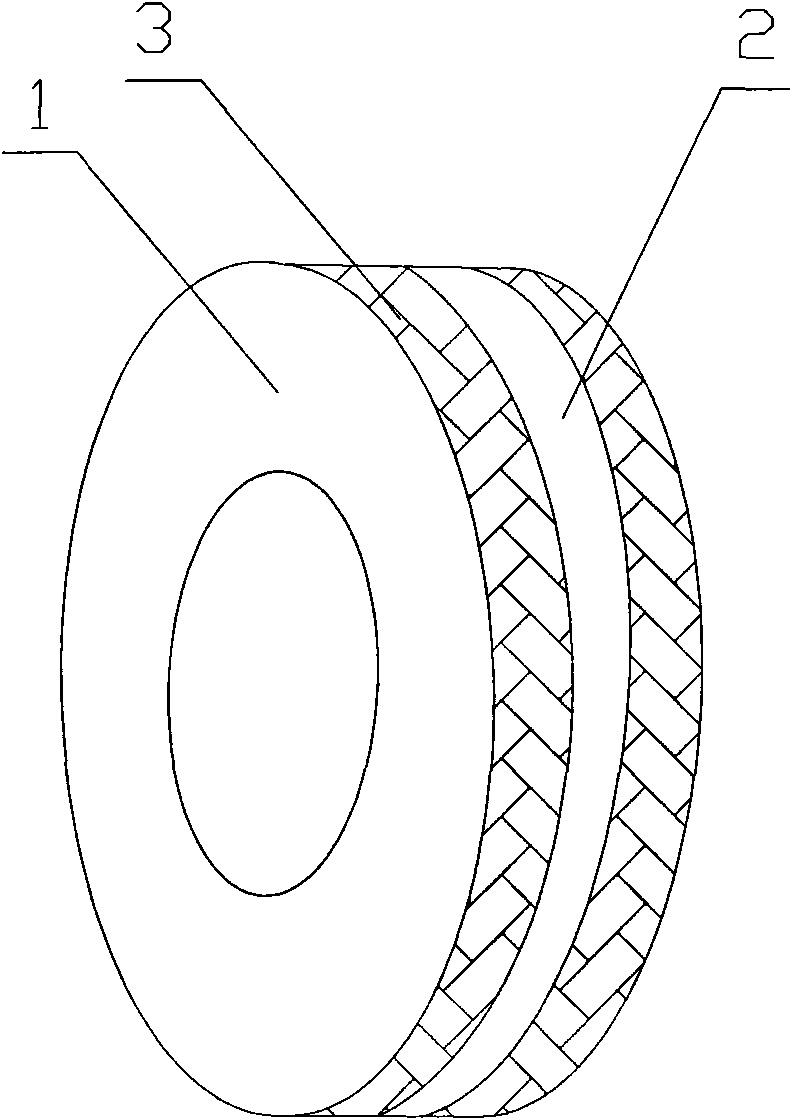

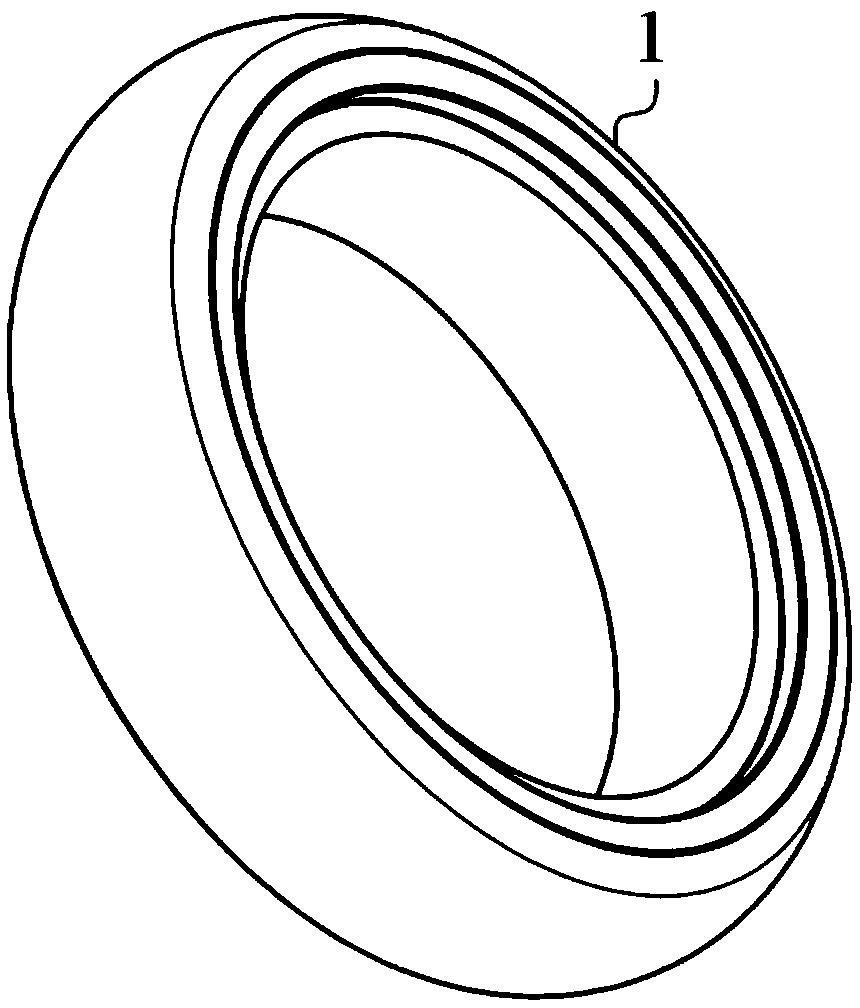

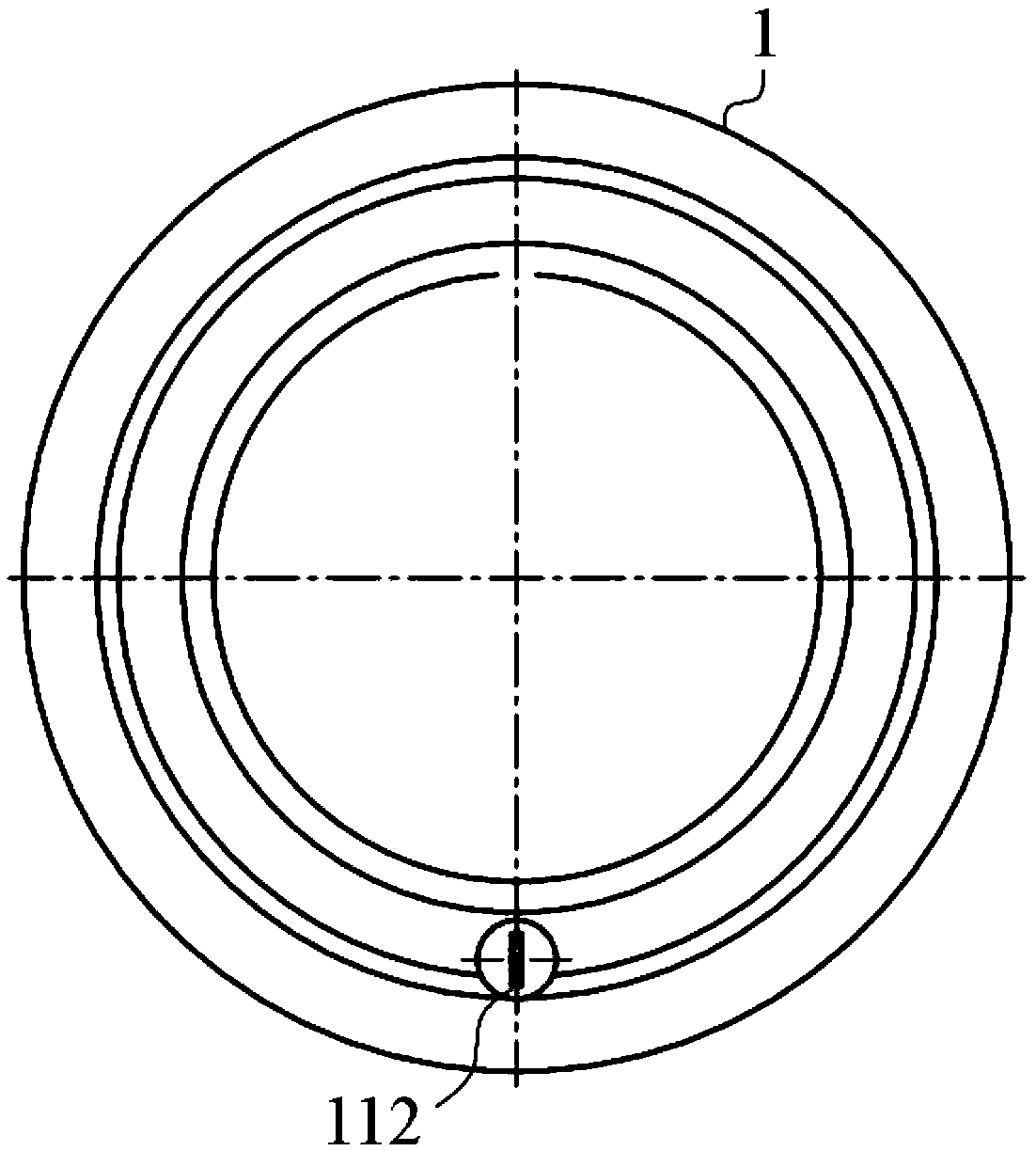

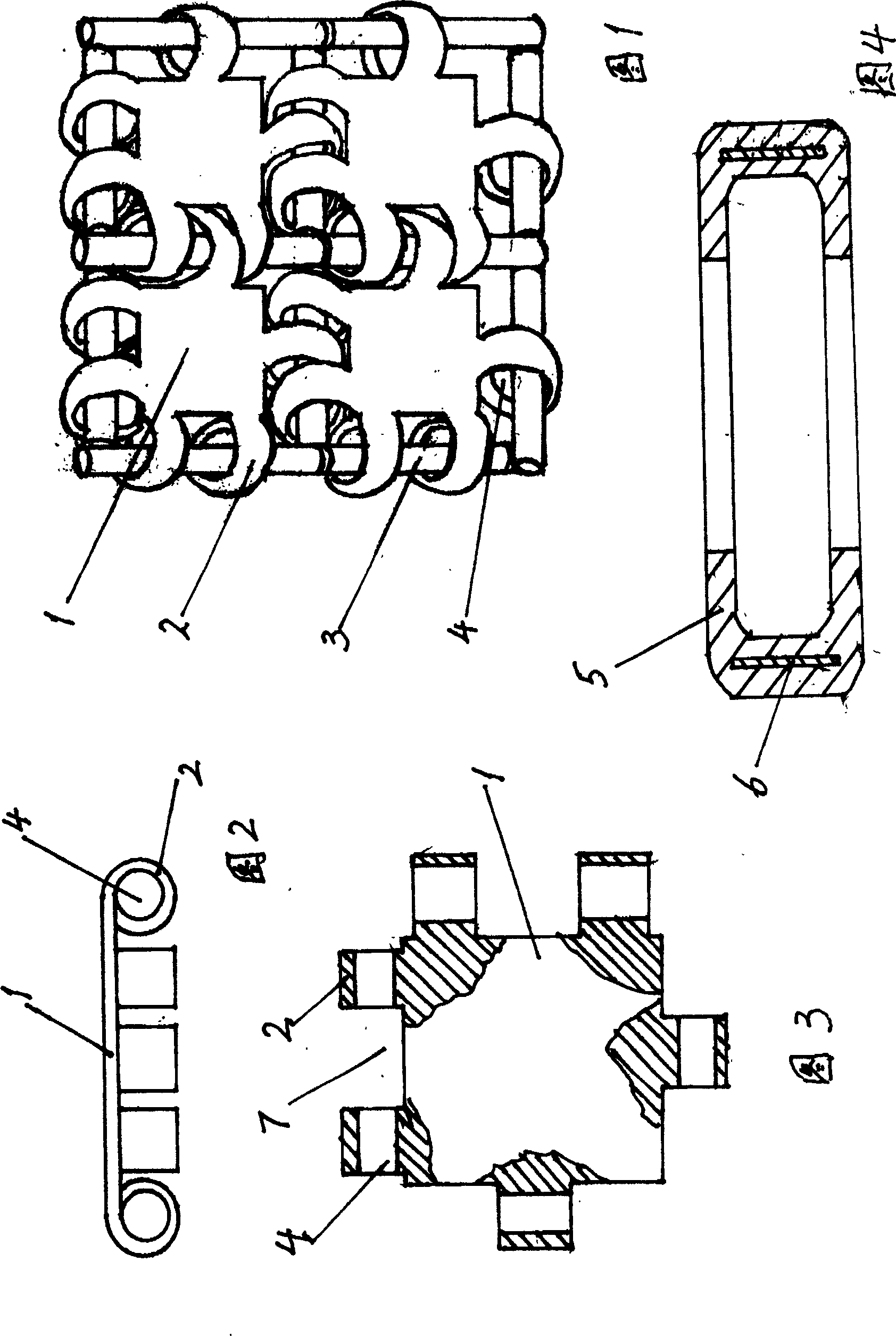

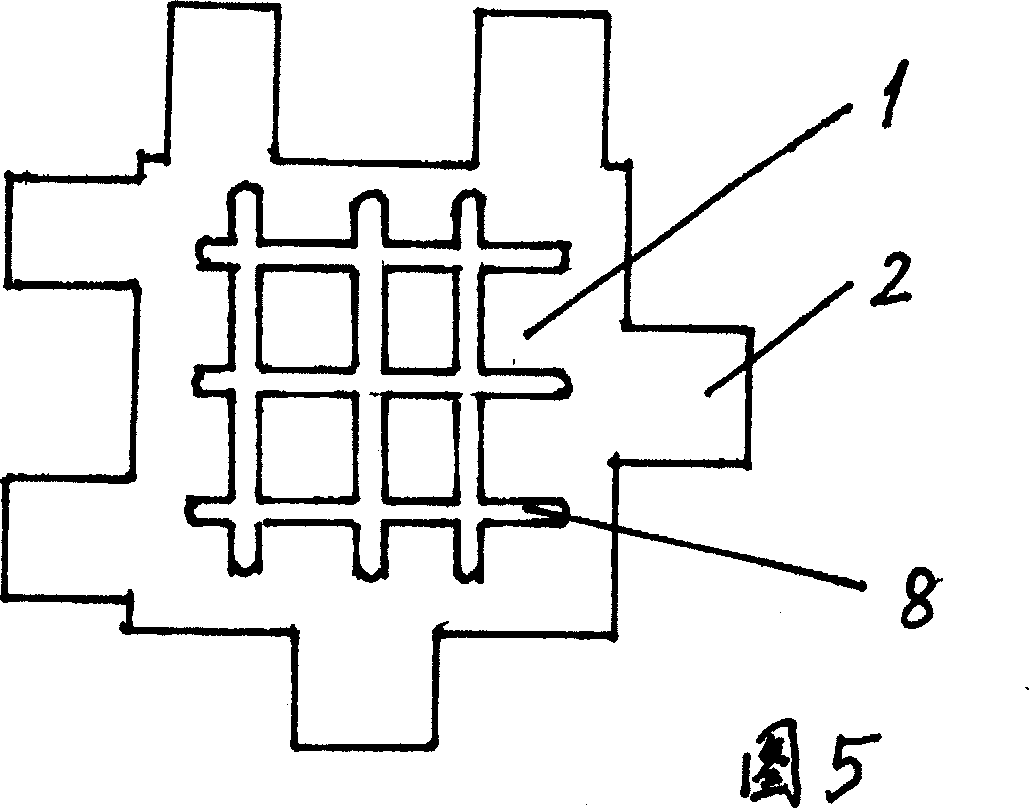

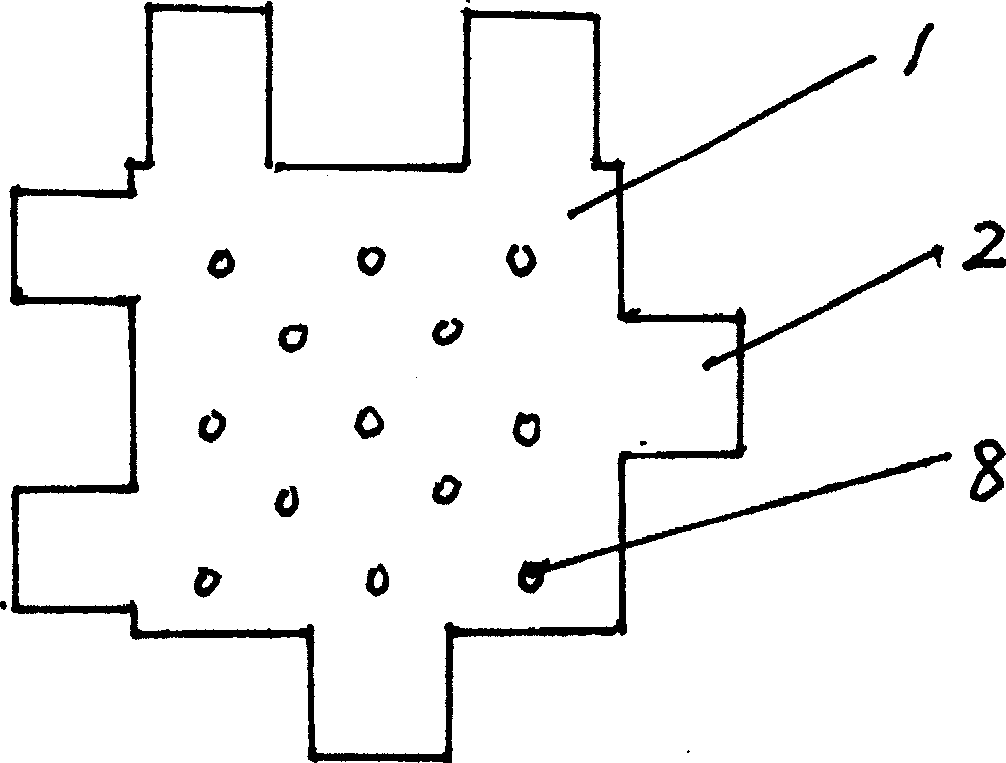

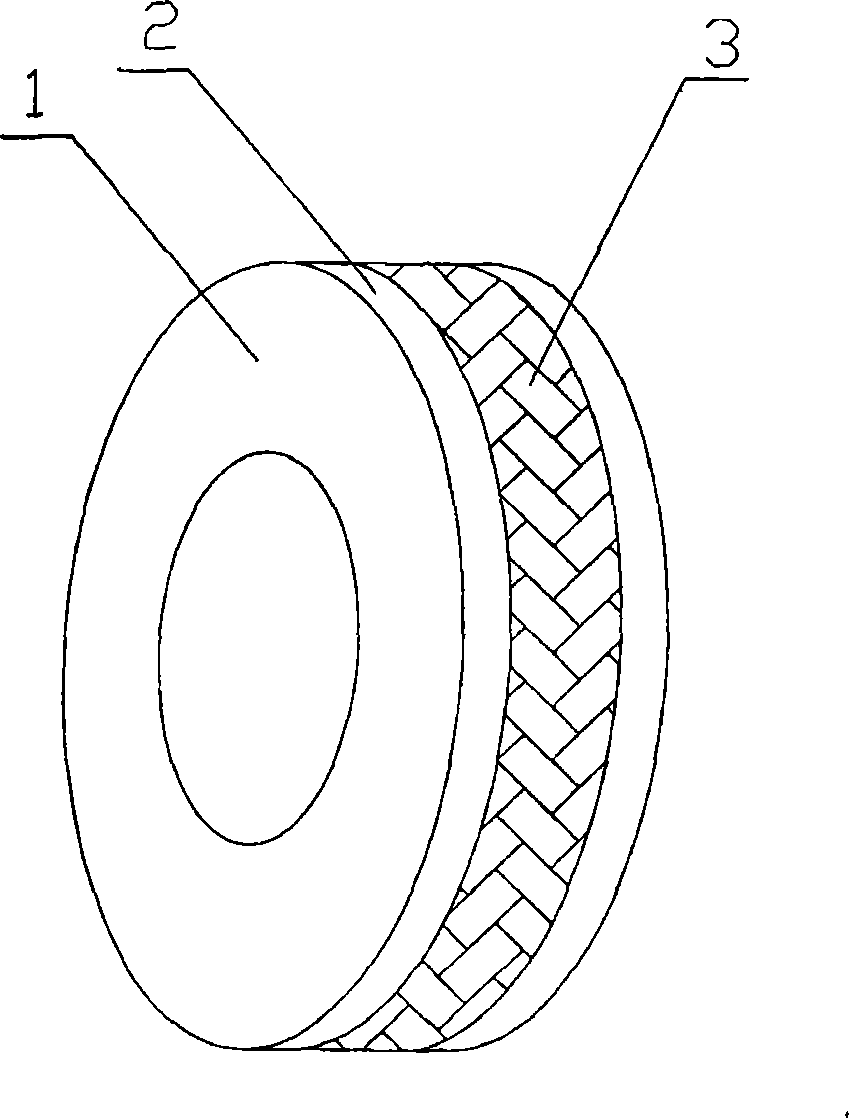

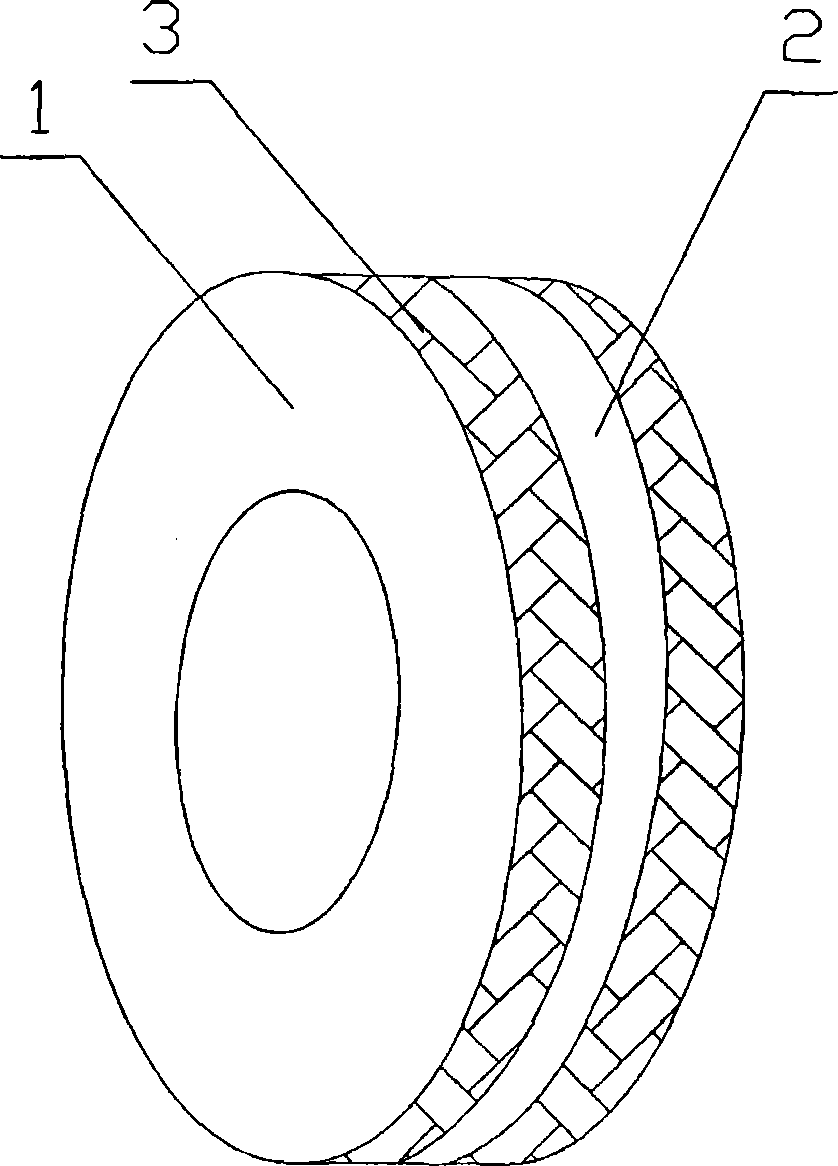

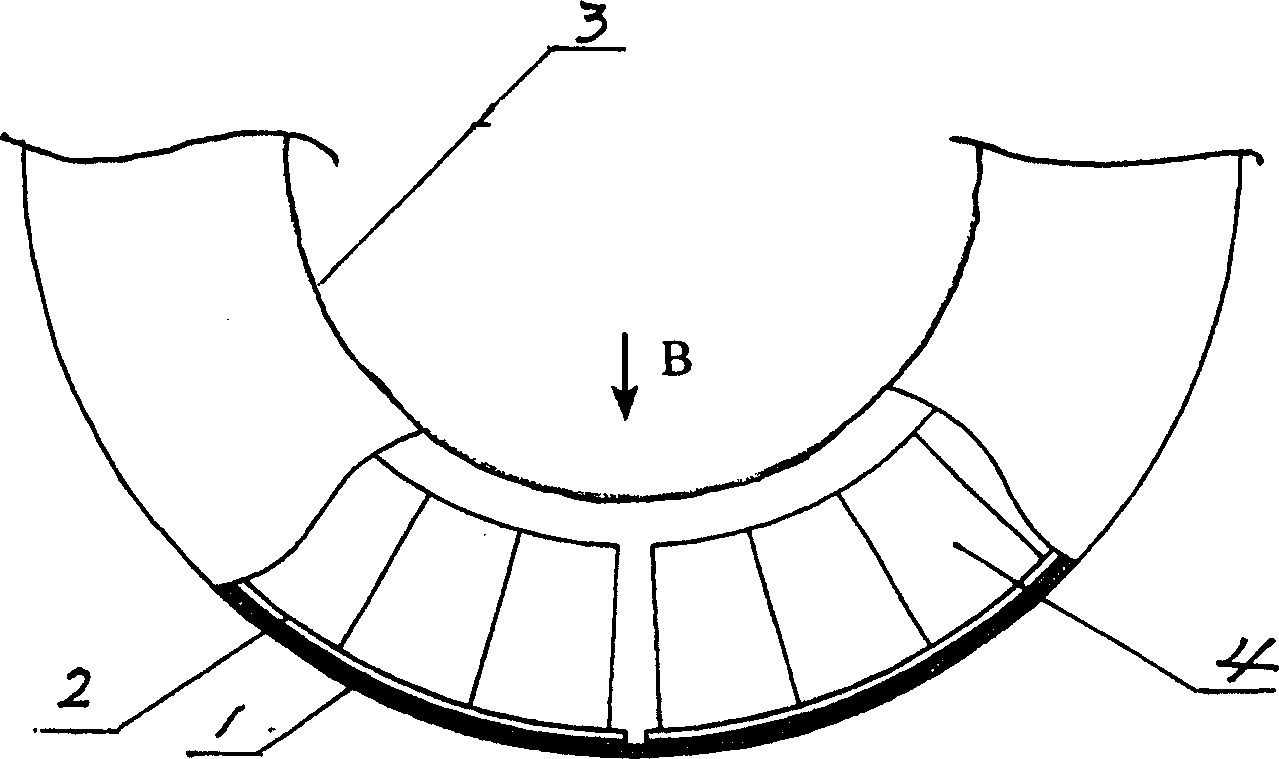

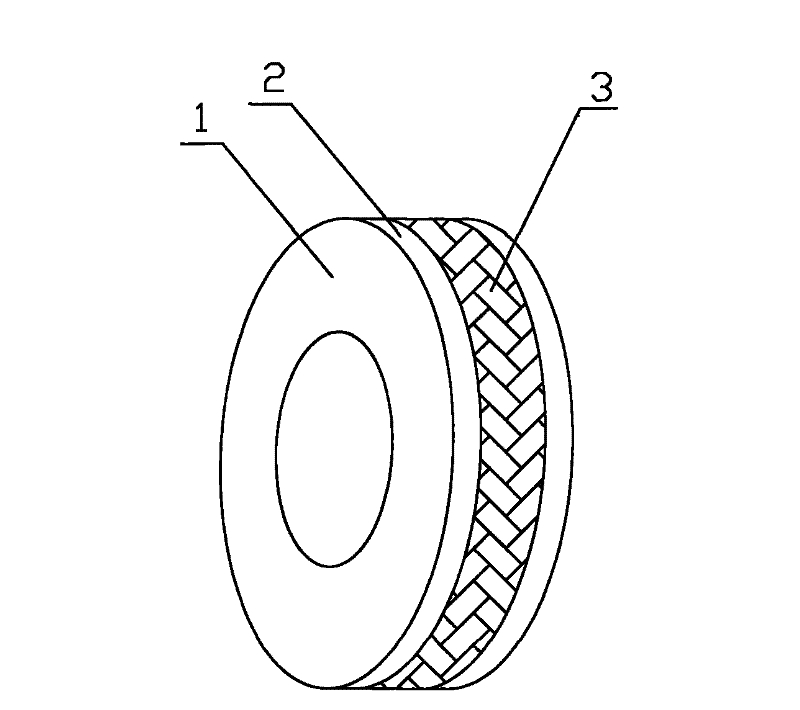

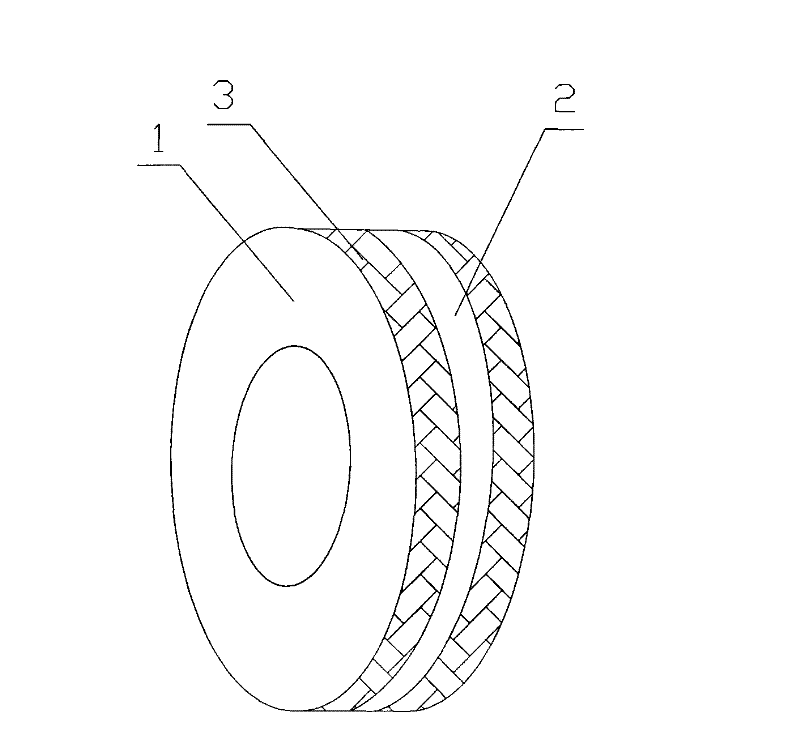

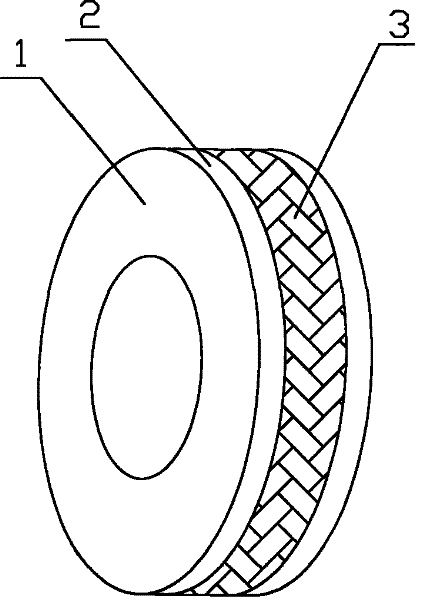

Penetration prevention safe tyre cyclic chain sheet belt

ActiveCN1754708AGuaranteed safe operationLess chance of blowoutPneumatic tyre reinforcementsTruckEngineering

Owner:HUNAN ZHONGMAN TIRE TECH CO LTD

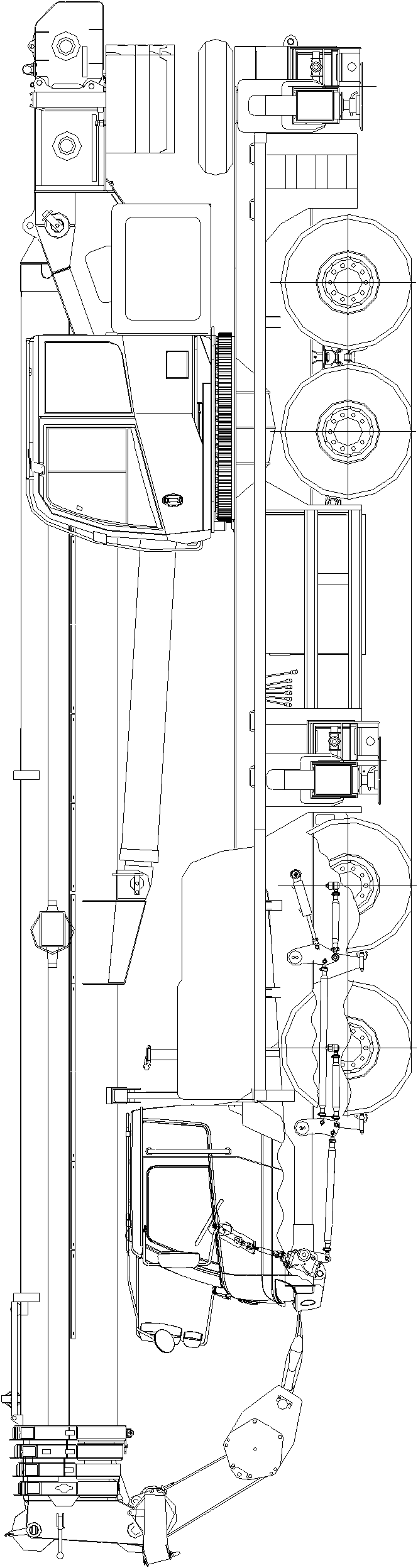

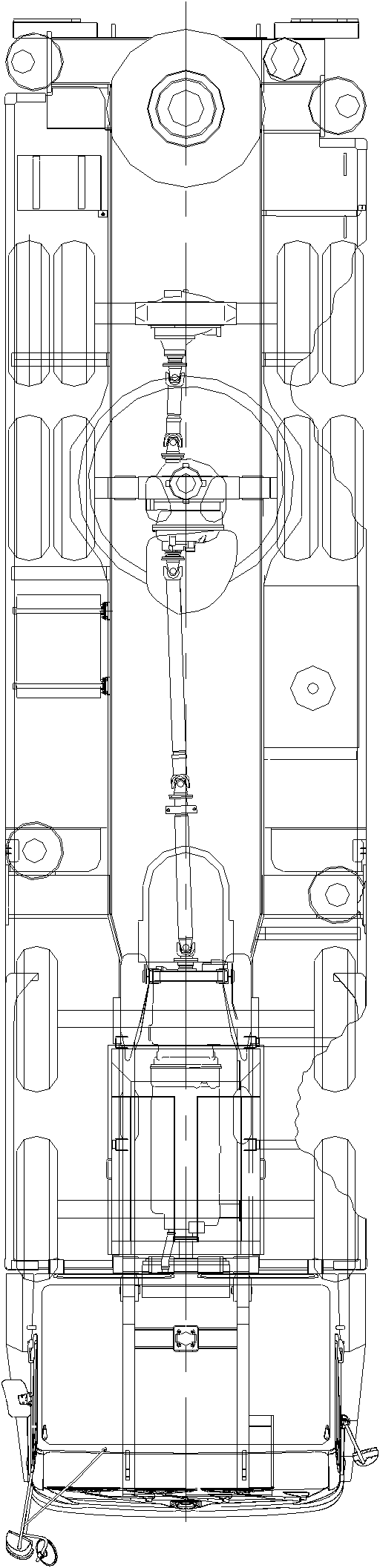

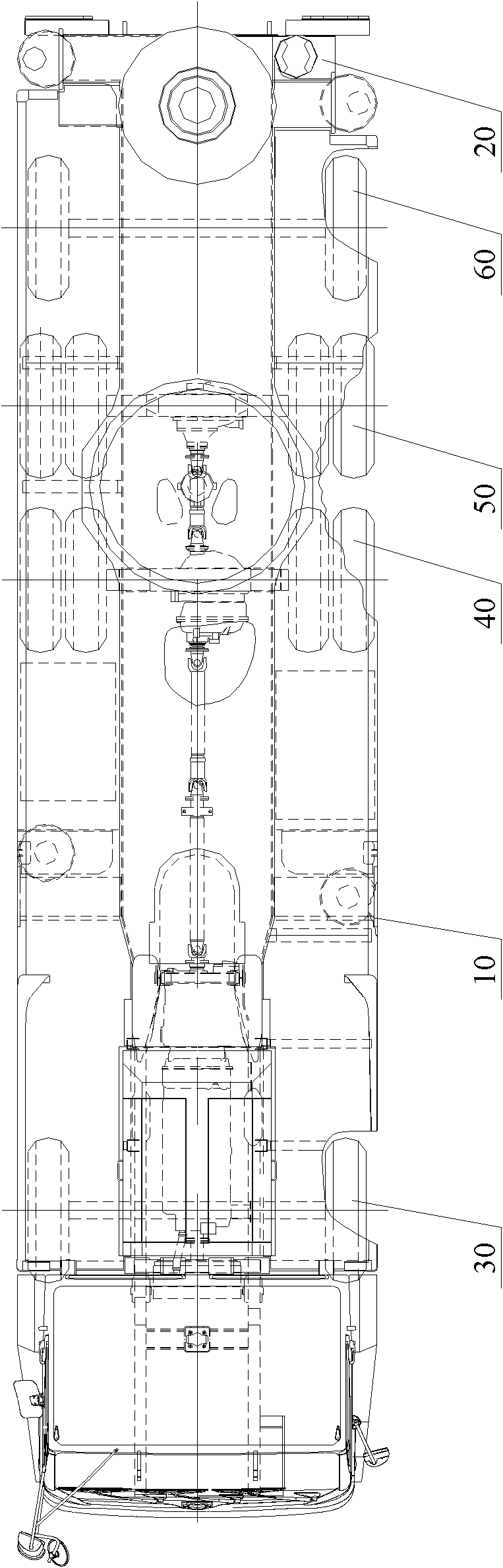

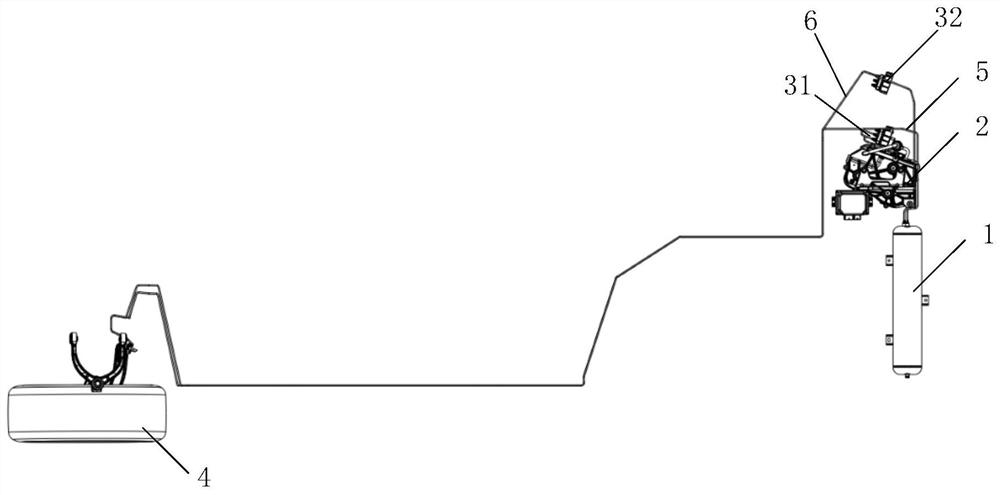

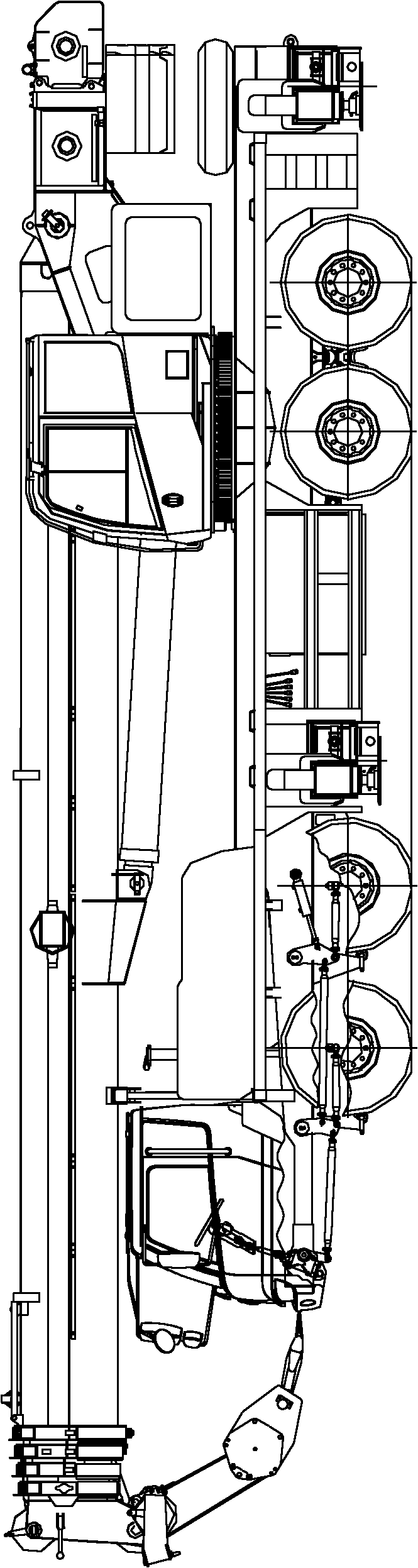

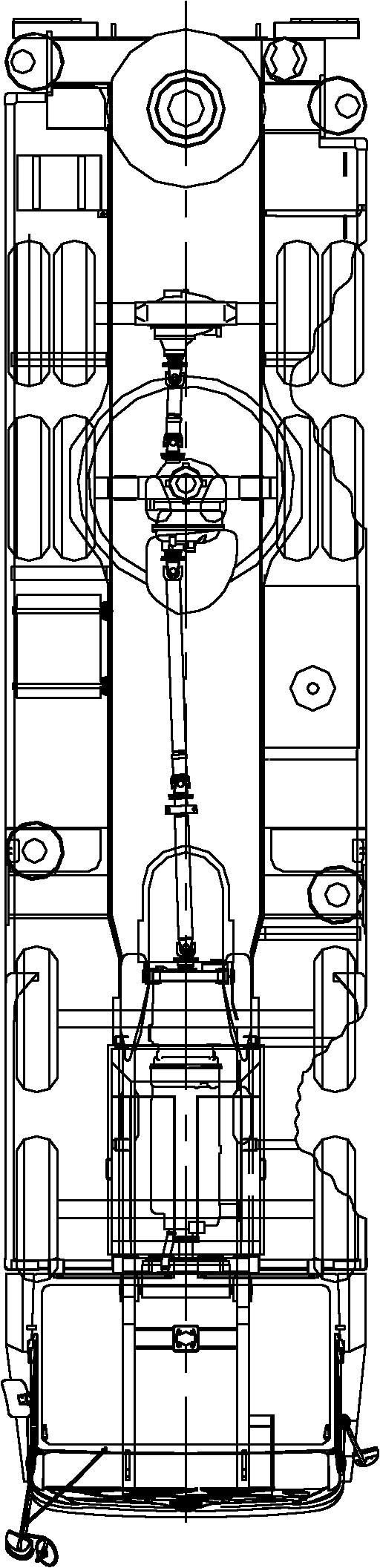

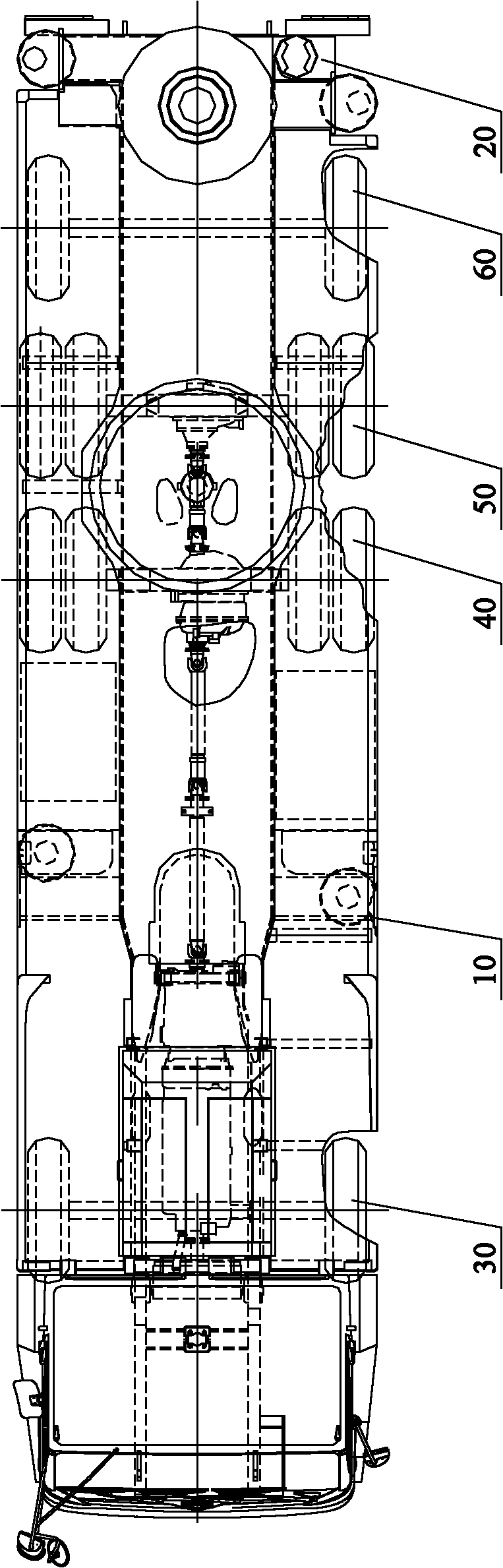

Four-axle automobile chassis and automobile crane with same

ActiveCN102424001AIncreased overall carrying capacityImprove carrying capacitySteering linkagesFluid steeringRolling chassisWheel and axle

The invention discloses a four-axle automobile chassis, which is provided with four axles, a front fixing support leg and a back fixing support leg, wherein the first axle is arranged at the front side of the front fixing support leg, the second axle, and the third axle and the fourth axle are arranged between the front fixing support leg and the back fixing support leg, wherein the first axle and the fourth axle are steering axles, and the second axle and the third axle are driving axles. Preferably, the first axle adopts a mechanical steering device and a steering assistor for driving the steering, and the fourth axle adopts a follow-up assistor for driving the steering. The four-axle automobile chassis provided by the invention can effectively balance the work load of each axle, so the carrying capability of the whole machine is improved, and simultaneously, the transition operation efficiency is further improved. On the basis, the invention also provides a four-axle automobile crane adopting the chassis.

Owner:XUZHOU HEAVY MASCH CO LTD

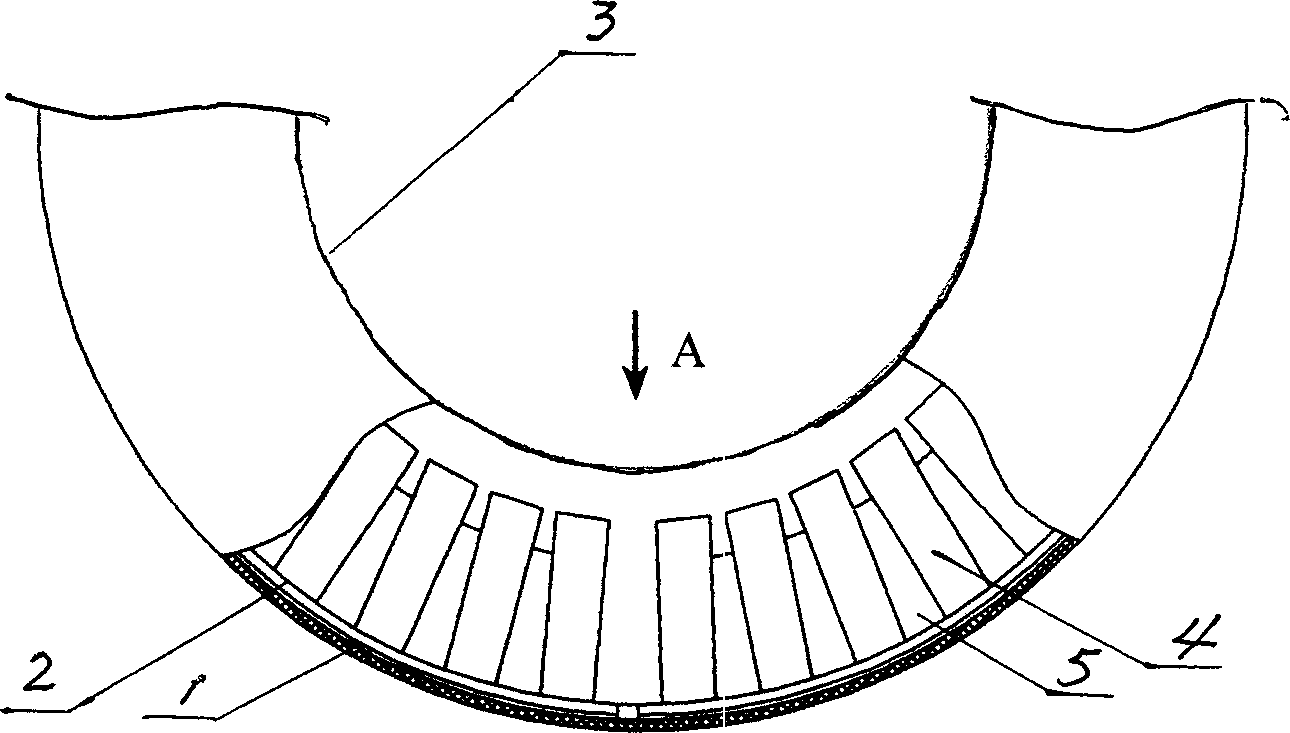

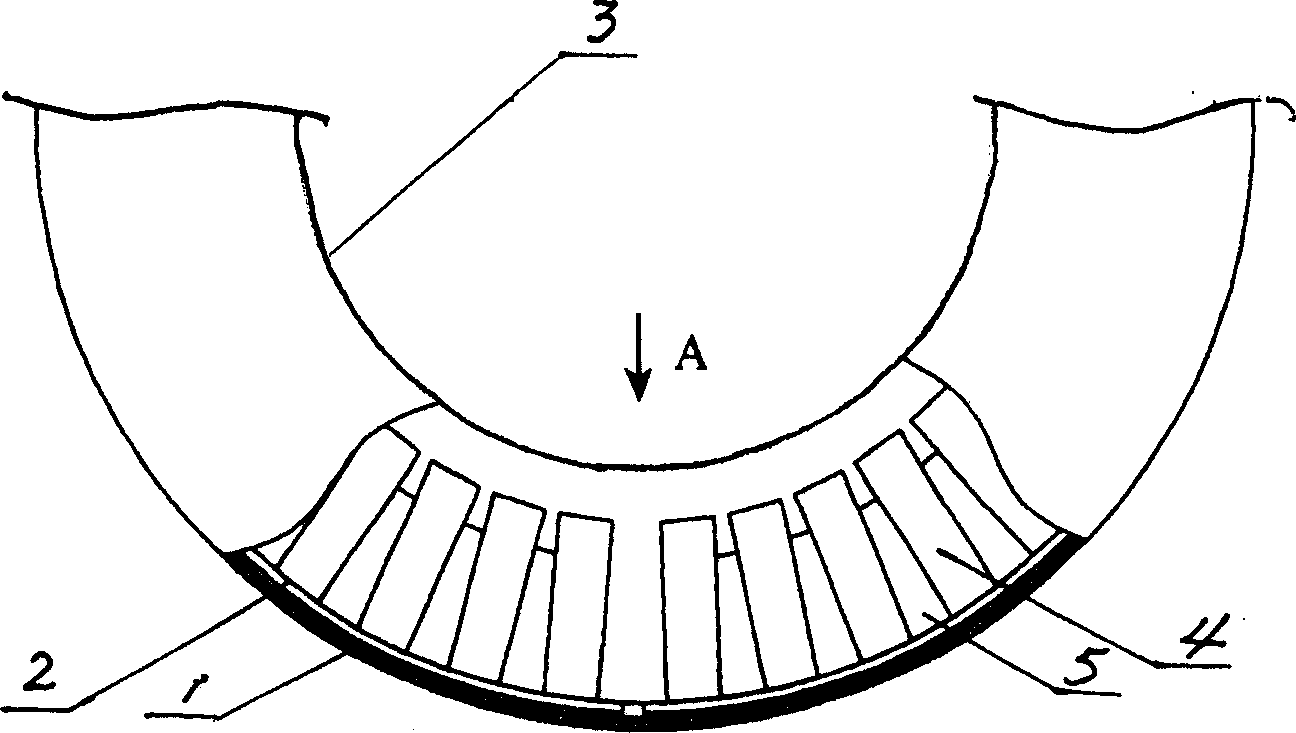

Method of retreading tyre

InactiveCN101549565AWithout breaking the balanceImprove handling comfortTyresMechanical engineeringTread

The invention relates to a method of retreading the old and useless full steel wire tyre by the meridian, comprising the steps as follow: milling the tyre surface, removing the vitiated tyre face and roughening the surface of the steel wire tyre by milling; gluing by coating the plasmagel on surface of the tyre; winding the new glued steel wire curtain cloth on the tread of tyre and adhering with the middle pad glue; adhering the matched type face glue on the tread of tyre, which wound by the glued steel wire curtain cloth, after the tyre face is adhered with glue; then sulphrizing in the tank that is sulphrizing the reinforced tread bracing layer into the sulphrizing tank. The invention will not damage the equilibrium of tyre, improve the controlling amenity, increase the anti-piercing and anti-explosion capability of the tread of tyre, prevent the skeleton of tyre from deforming and improve the retreading rate of tyre. The thickness of glue steel wire curtain cloth installed with the middle pad glue increase the cementation effect between tyre body and the tyre face, improve the anti-tearing capacity of tread block, decrease chunking and improve the bearing and buffer capacity of the tyre.

Owner:张乐平

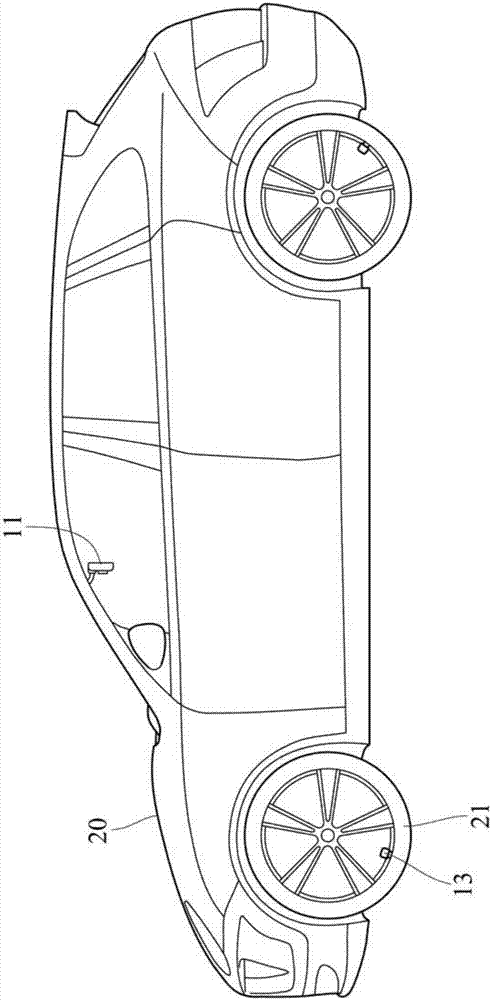

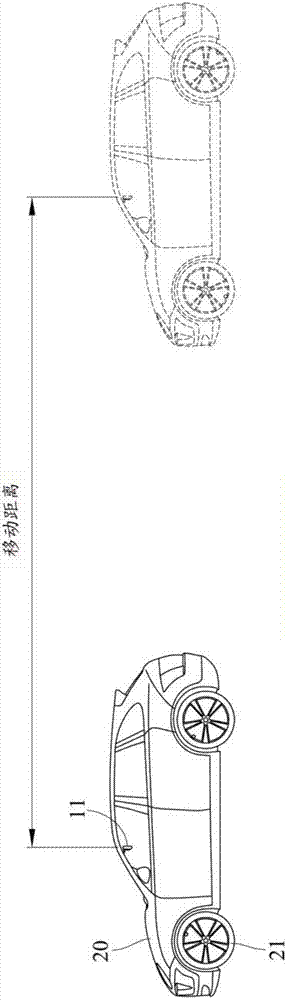

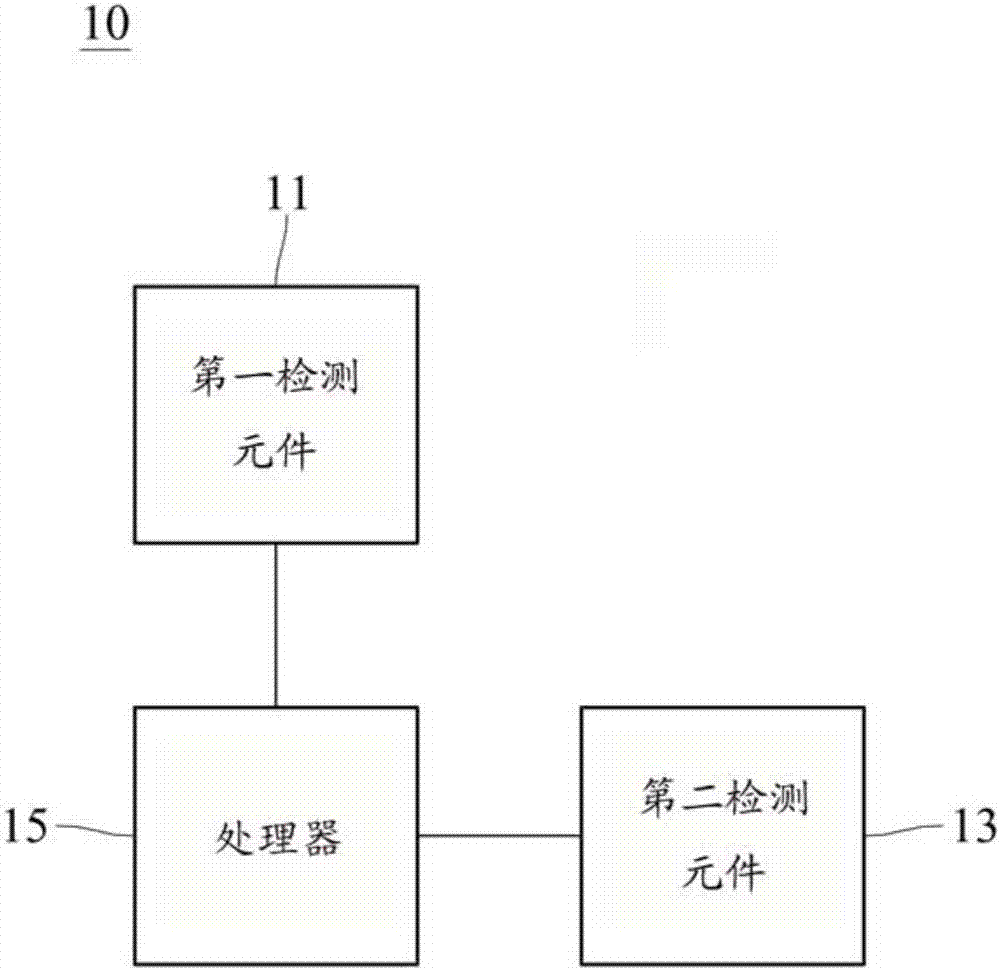

Method, system, and computer-readable medium for detecting wheel tread depth

ActiveCN107153008AReduce the chance of a flat tireMechanical depth measurementsTyre measurementsTreadAutomotive engineering

A method, a system and a computer-readable medium for detecting a wheel tread depth include a first detector, a second detector and a processor. The first detector is configured to detect a moving distance of a vehicle moved by at least one wheel. The second detector is configured to detect a number of tunes of the wheel while the vehicle moves the moving distance. The processor is electrically connected to the first detector and the second detector. The processor is configured to compute a current diameter of the wheel according to the moving distance and the number of tunes of the wheel and determine a parameter of the tread pattern of the wheel according to the current diameter of the wheel and a reference value.

Owner:WISTRON CORP

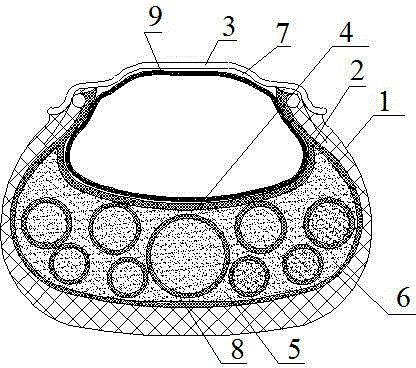

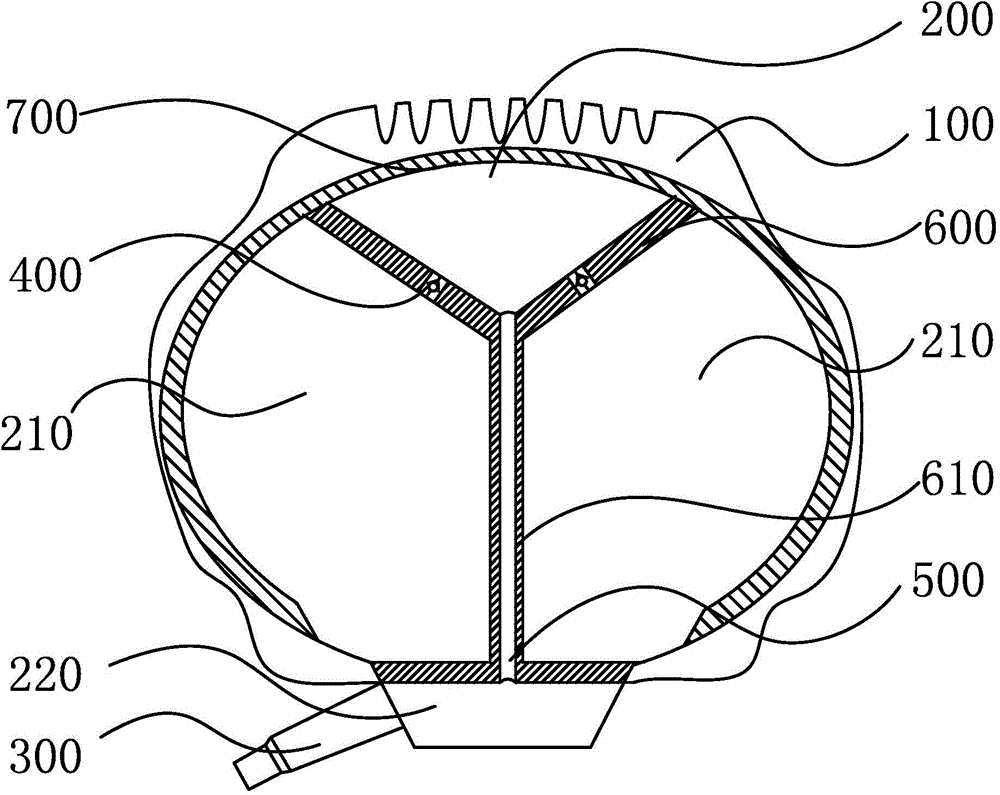

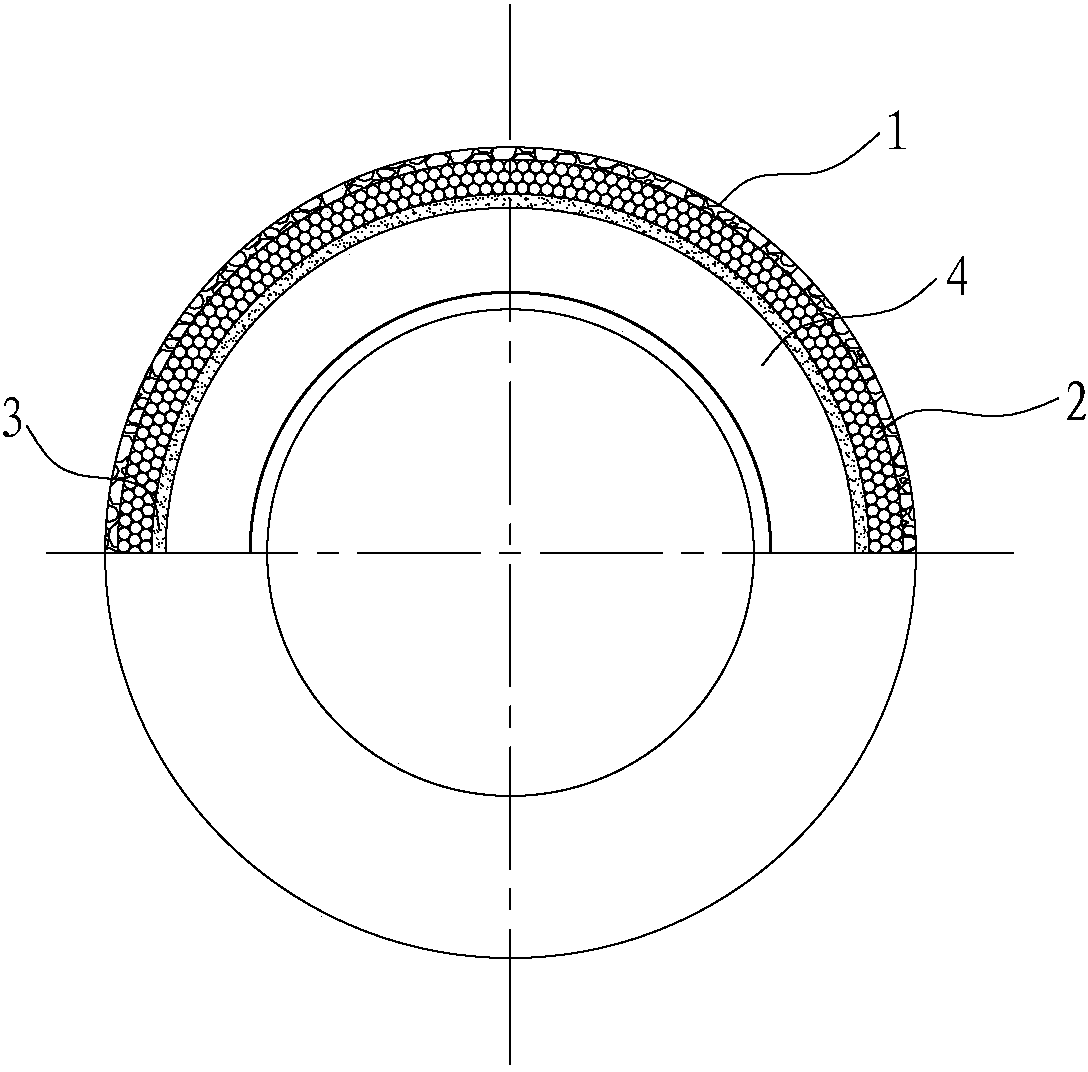

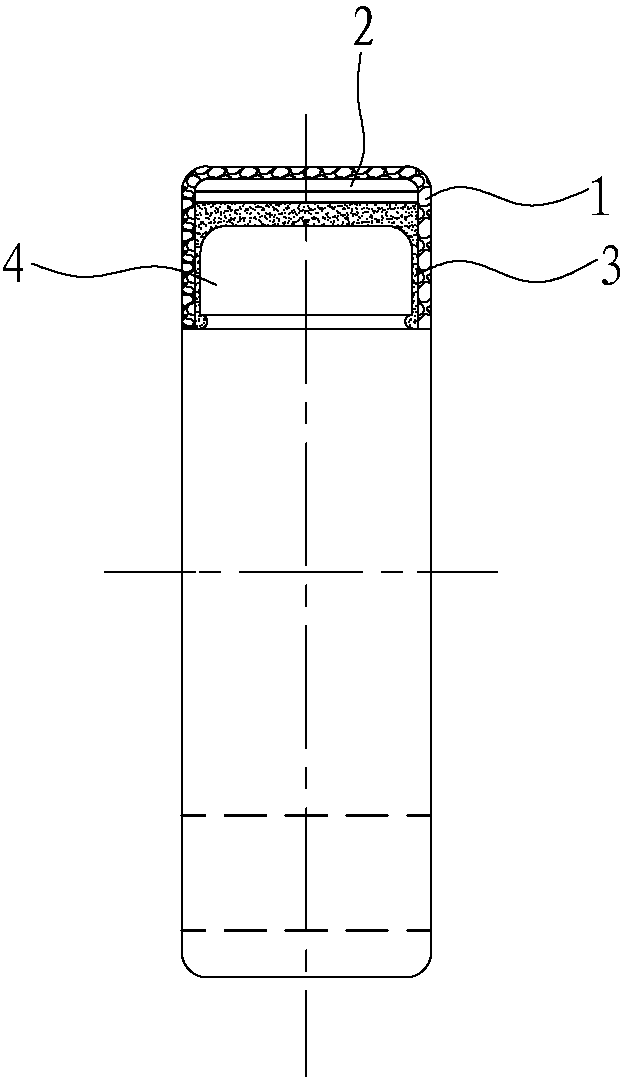

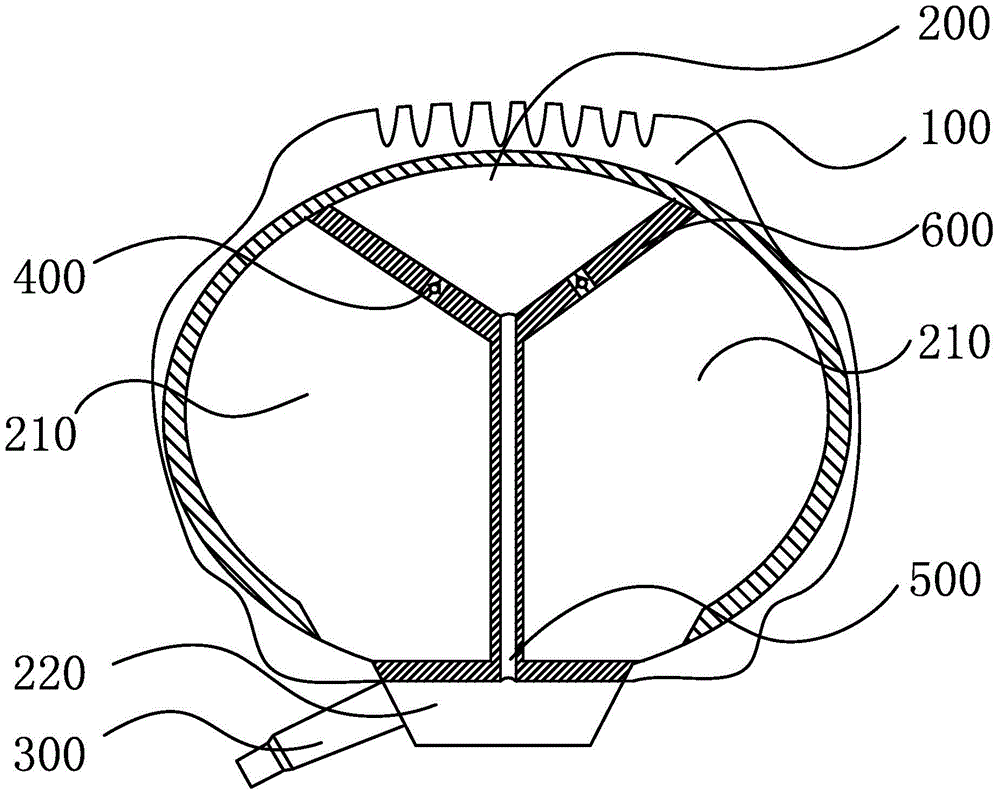

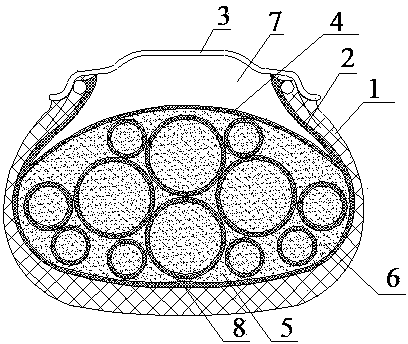

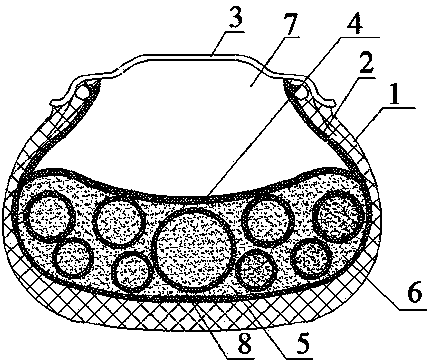

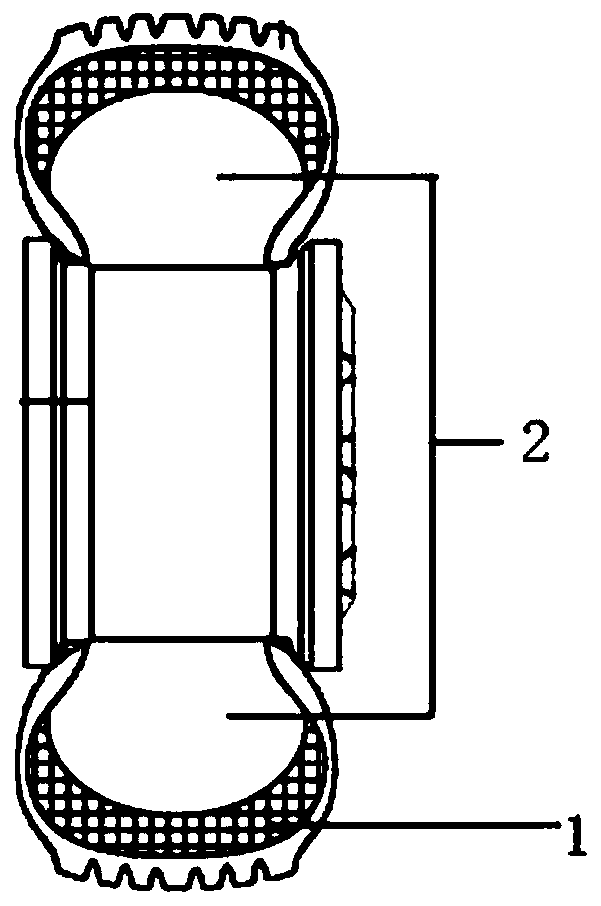

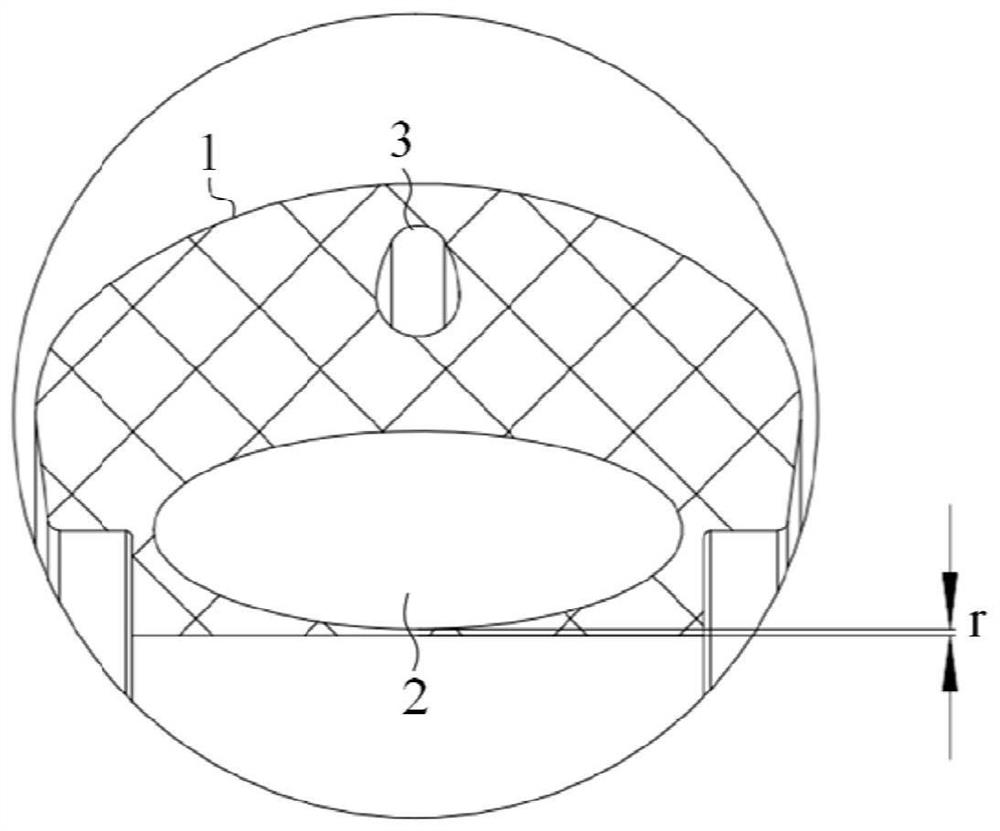

Reinforced anti-puncture run-flat composite tire

InactiveCN104149551AReduce damage rateDoes not affect drivingTyresPneumatic tyre reinforcementsComposite materialAir chamber

The invention discloses a reinforced anti-puncture run-flat composite tire which comprises an outer tire, an airtight inner rubber layer, an airtight rubber spacing, a reinforced foamed solid inner tire, an annular rubber pipe and an independent air-filled inner tire, wherein the airtight inner rubber layer is adhered to the inner wall of the outer tire; the airtight rubber spacing is transversely arranged in the middle of the airtight inner rubber layer; the space between the upper part of the airtight rubber spacing and the lower part of a hub is an air chamber; the independent air-filled inner tire is arranged in the air chamber; the reinforced foamed solid inner tire is arranged below the airtight rubber spacing; the annular rubber pipe is longitudinally arranged in the reinforced foamed solid inner tire; the reinforced foamed solid inner tire and the annular rubber pipe are filled with elastic foam materials. Compared with the prior art, the reinforced anti-puncture anti-explosion composite tire is simple in structure, easy to process, anti-puncture and run-flat; a tire after air leakage is the same as a tire with reduced air, so that normal driving of vehicles is completely not influenced; the composite tire is safe and durable, and has very good promotion and application values.

Owner:JINAN GAODA INFORMATION TECH

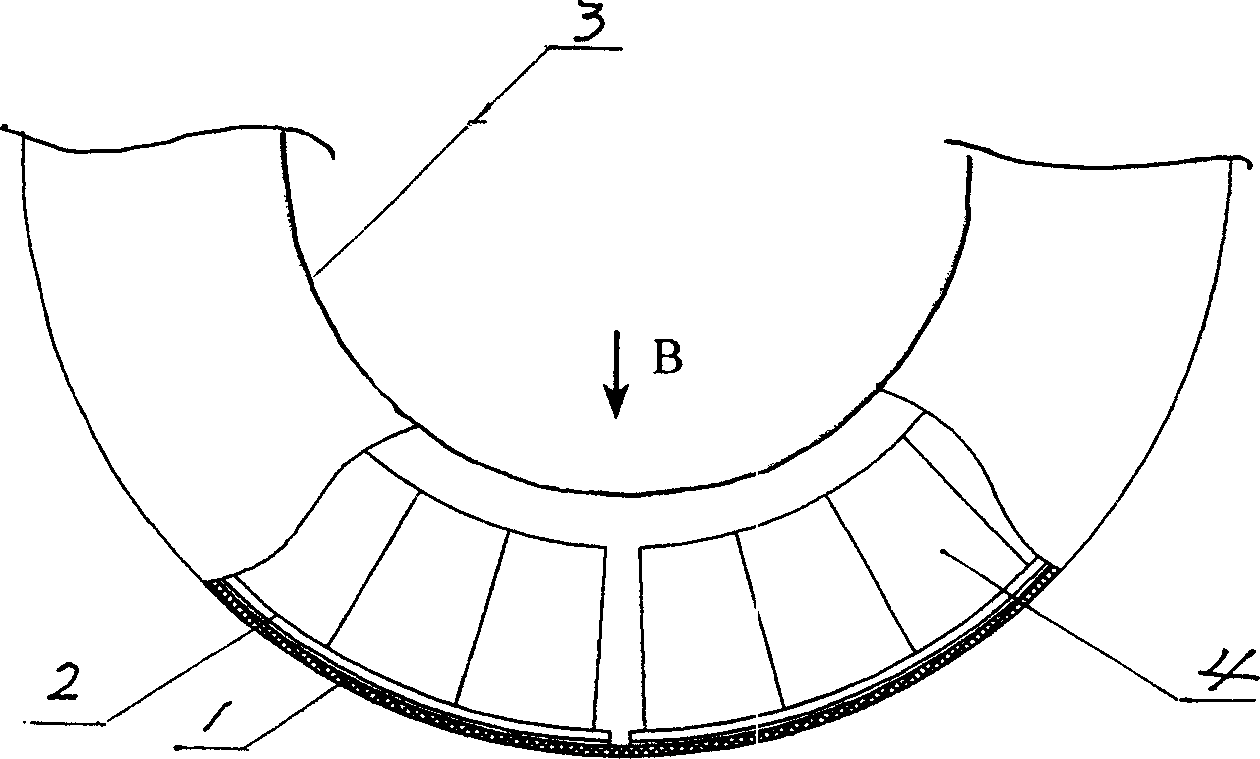

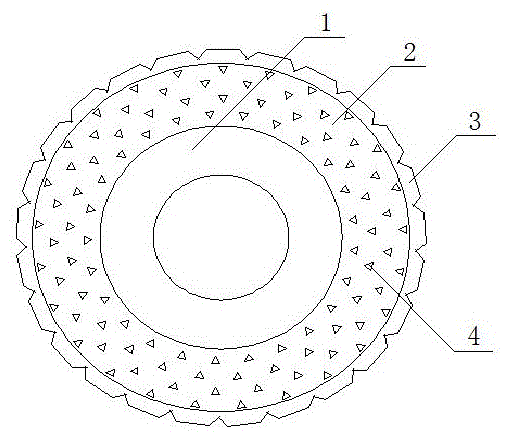

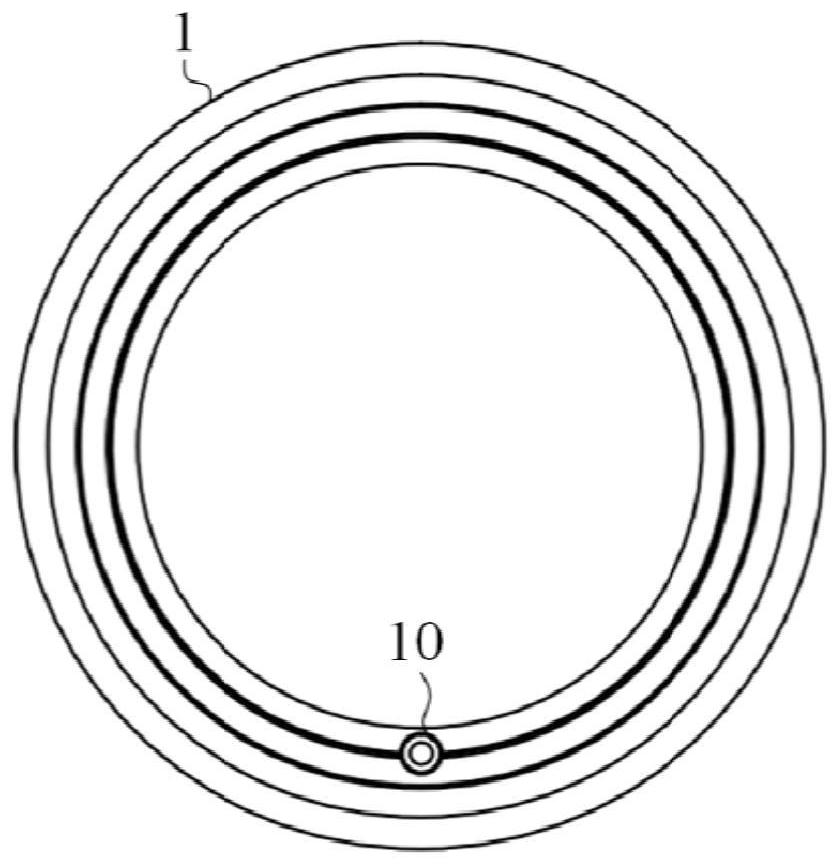

Multi-air-chamber explosion-proof tyre

ActiveCN104589924AIncrease volumeImprove stabilityWith separate inflatable insertsWith multiple inflatable chambersEngineeringStearic acid

The invention relates to a multi-air-chamber explosion-proof tyre and belongs to the technical field of tyres. The multi-air-chamber explosion-proof tyre comprises a tire body and a plurality of chambers, wherein the chambers comprise an inflating chamber and a plurality of air storing chambers; a first separation layer is arranged between the inflating chamber and each air storing chamber; a check valve is arranged on each first separation layer; a second separation layer is arranged between every two adjacent air storing chambers; the tyre further contains a tyre inner wall; the tyre inner wall is prepared into a strip-shaped body from a layer of macromolecular composite material, wherein the macromolecular composite material is composed of the following components: (A) 15.5-17.0% of butadiene styrene rubber, 0.25%-0.35% of a plasticizer, and 0.1%-0.5% of a softening agent, (B) 6%-10% of petroleum resin, 10%-13% of rosin pentaerythritol, 2%-5.5% of nano graphite, 4%-11% of carboxymethylcellulose and 52%-59% of de-ionized water, and (C) 0.05%-0.5% of stearic acid and 0.05%-0.3% of lauryl sodium sulfate. The tyre has a simple structure and long service life.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +1

Explosion-proof tyre

InactiveCN1597372AReduce the chance of a flat tireExtended service lifeNon-inflatable tyresBlow outElectrical and Electronics engineering

Owner:李靖

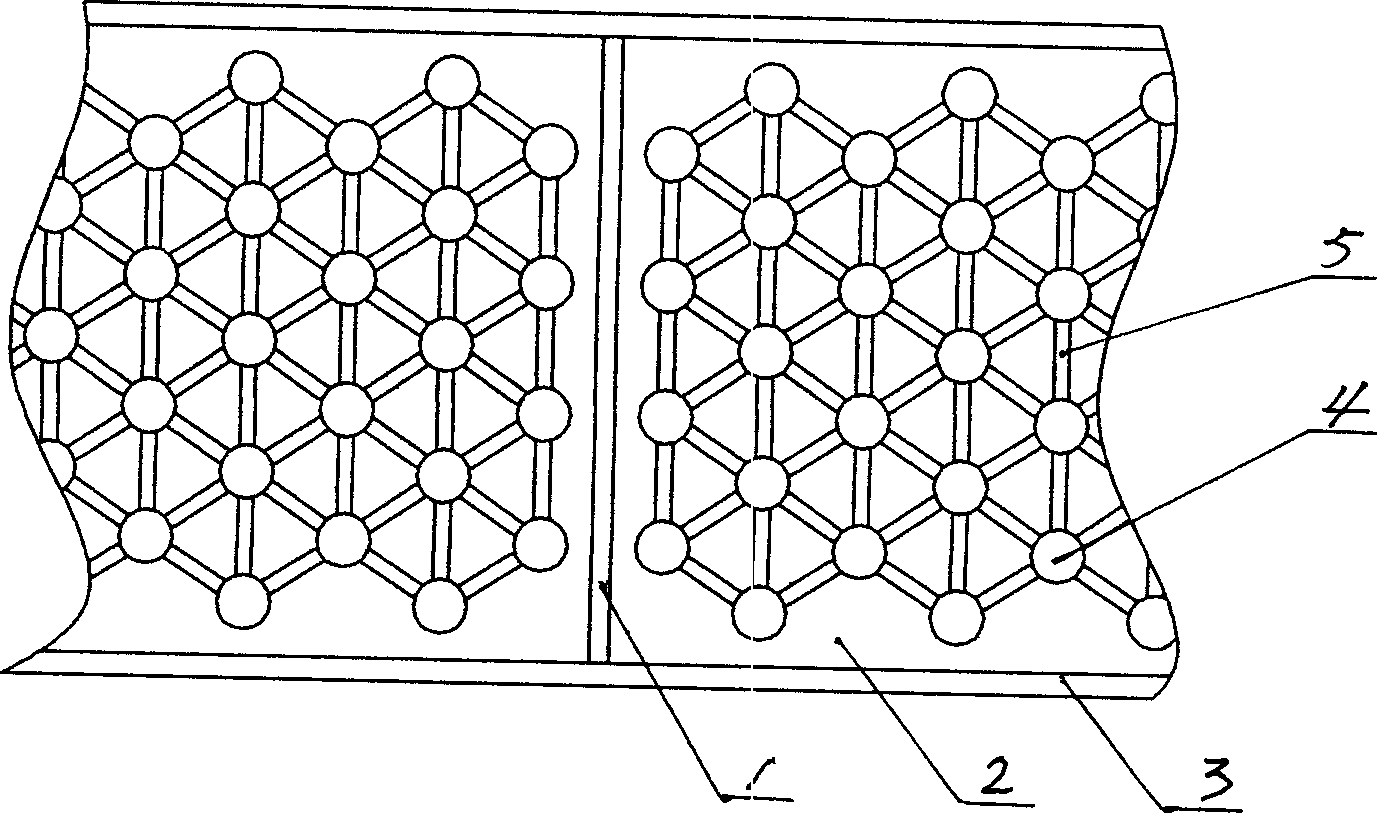

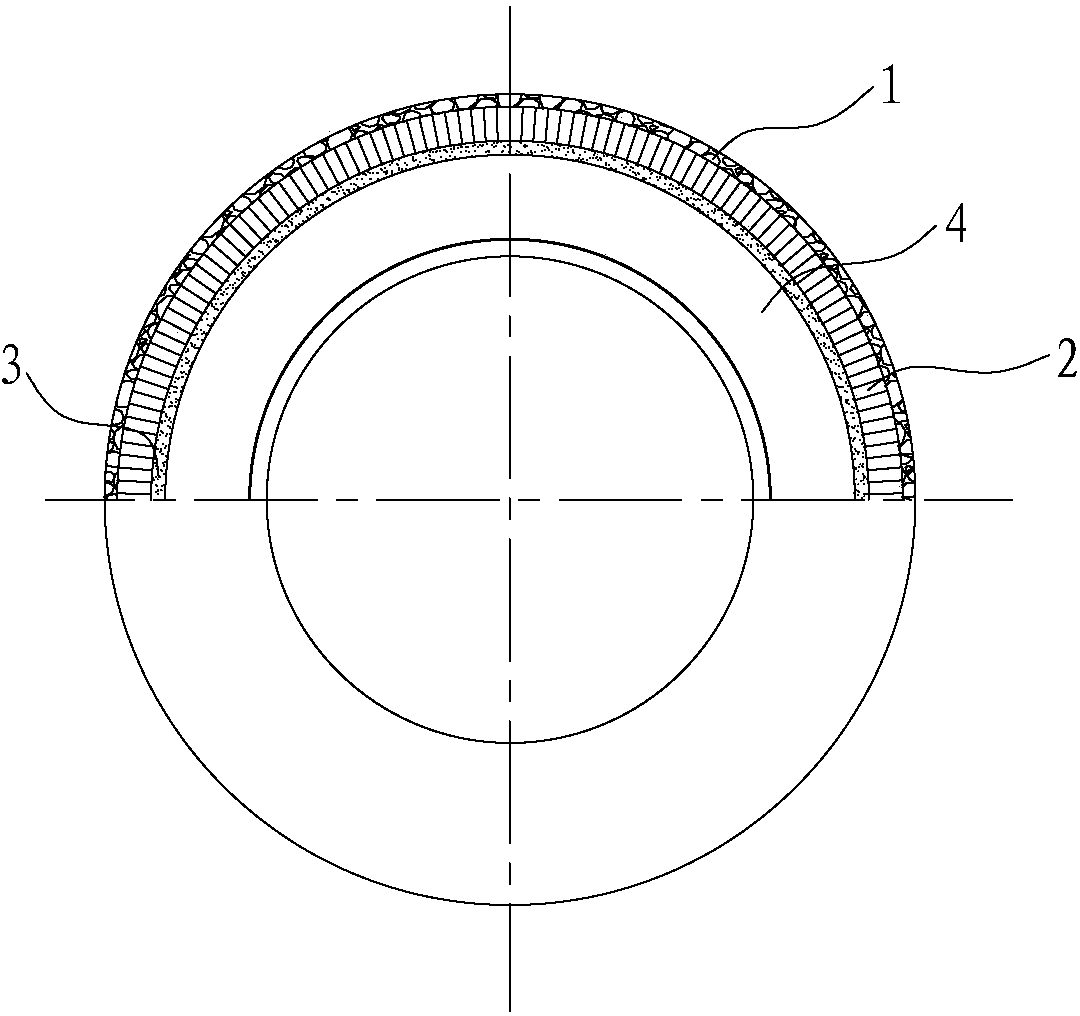

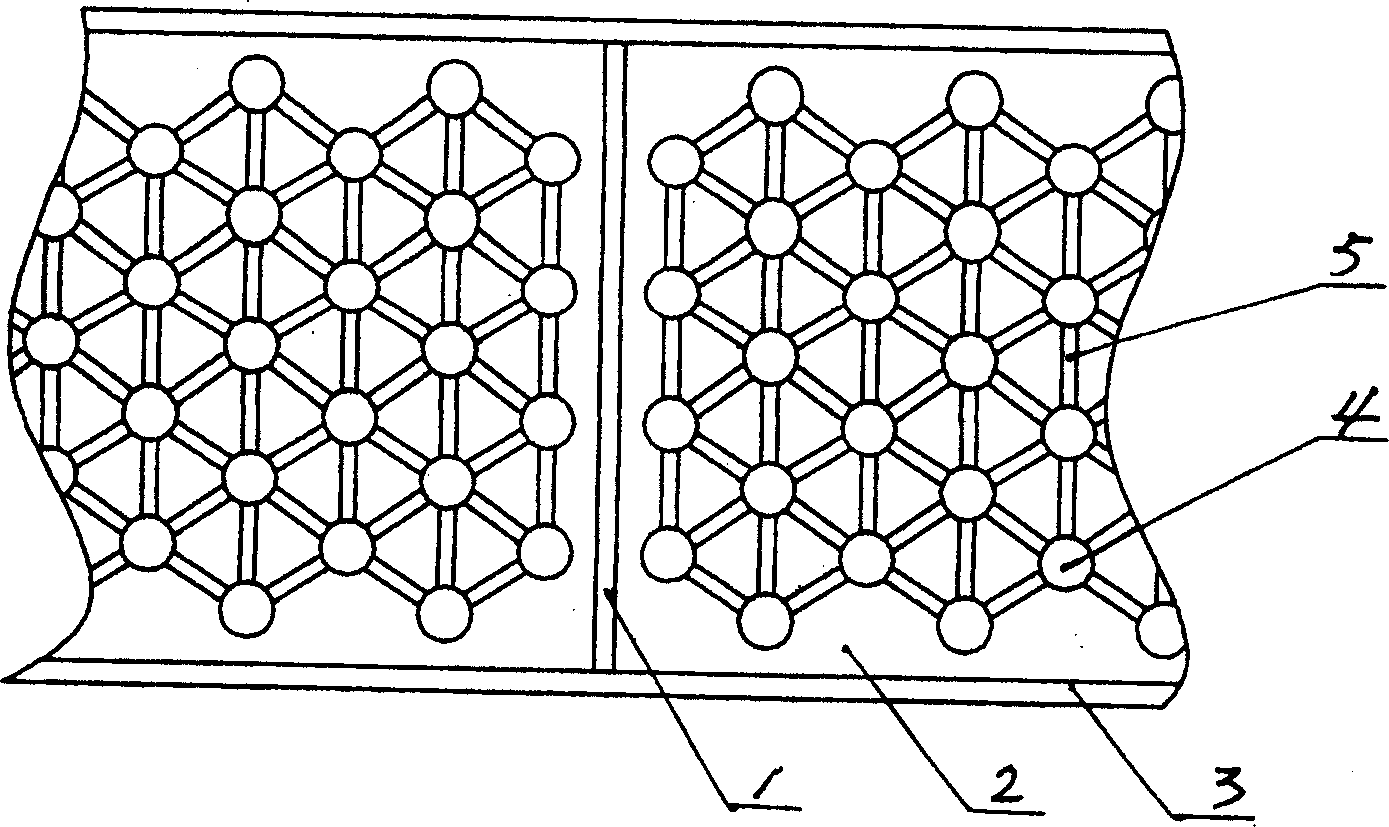

Anti-vibration, buffering and anti-explosion tire

InactiveCN103381738AIncrease elasticityReduce vibrationPneumatic tyre reinforcementsHoneycombRoad surface

The invention discloses an anti-vibration, buffering and anti-explosion tire which comprises an outer layer tread adhesive layer and an inner layer carcass steel wire layer, wherein a honeycomb buffering layer is arranged between the outer layer tread adhesive layer and the inner layer carcass steel wire layer, and an inflation chamber is formed in the inner layer carcass steel wire layer. The honeycomb buffering layer is a structural layer made of elastic buffering materials and is provided with a plurality of honeycomb holes. Air sealed in the honeycomb holes can increase elasticity of tires, reduce vibration, improve the buffering performance and avoid jumping caused by excessive inflation. Meanwhile, the anti-vibration, buffering and anti-explosion tire can improve protection for vehicles and reduce road surface damage.

Owner:XIAMEN UNIV OF TECH

Leakproof airbag cavity tire

PendingCN109591519AReduce the chance of a flat tireStable supportTyresPneumatic tyre reinforcementsVulcanizationEngineering

The invention discloses a leakproof airbag cavity tire, and belongs to the field of tires. The leakproof airbag cavity tire comprises a tire body and further comprises bag cavities which are bag-shaped cavities formed inside the tire body; the adjacent bag cavities are connected in series through a channel; reinforcing holes are formed between a tire face of the tire body and the bag cavities; a valve hole formed in the side face of the tire body, an inflating valve installed in the valve hole, an inflating valve cap movably connected to the end of the inflating valve and a sealing plug are further included, and the bag cavities communicate with the outside of the tire body; the inflating valve is placed on the side face of the tire body; the inflating valve cap seals the inflating valve;the sealing plug is fixedly connected to the tail end of the inflating valve cap; and the inner surface of each bag cavity is provided with an airtight layer. According to the leakproof airbag cavitytire, the bag cavities which are connected in series through the channels are arranged inside the tire body, the degree of air leakage when the tire is punctured is greatly reduced, and tire burst caused when the air leaks is prevented; and according to the tire, mastication, mold assembly, injection, mold opening, secondary mold assembly, air injection, vulcanization, pressure relief, airtight layer preparation and secondary mold opening are carried out for direct molding, and production and manufacturing are easy.

Owner:ANHUI GVG NEW MATERIAL CO LTD

Used tire retreading method

The invention relates to a used tire retreading method. The method comprises the following steps: selecting a tire body capable of being retreated; cutting and grinding the surface of the tire body; sewing a crack, and reinforcing the crack by utilizing a liner; smearing adhesive onto the tread under a vacuum state; press-fitting a tread adhesive strip onto the tread of the tire body; finally vulcanizing. The used tire retreading method has beneficial effects that by adopting the retreading method, the waste of resource is greatly reduced, the retreaded tire is good in quality, high in balance quality and low in flat tire rate, the tire body is subject to high temperature and high pressure in the retreading process, factors causing the aging of the tire body can be reduced, the retreading times of the tire body can be increased, and the service life of the tire body can be prolonged.

Owner:JINAN LISHEN TIRE CYCLIC UTILIZATION TECH CO LTD

Multiple-air chamber anti-explosion tyre with high-performance one-way valves

ActiveCN104589923AImprove stabilityReduce the chance of a flat tireWith separate inflatable insertsWith multiple inflatable chambersFiberCarbon fibers

The invention relates to a multiple-air chamber anti-explosion tyre with high-performance one-way valves and belongs to the technical field of tyres. The tyre comprises a tyre body and a plurality of cavities, wherein the cavities comprise air inflation cavities and a plurality of air storage cavities; a first separation layer is arranged between the air inflation cavity and the air storage cavities; the one-way valve is arranged on the first separation layer; a second separation layer is arranged between two adjacent air storage cavities; the one-way valve comprises a valve body, a piston, a pressing cap and a seal layer between the valve body and the pressing cap; the piston and the seal layer of the one-way valve are made of a composite material; and the composite material comprises the following components: 8-20% of polytetrafluoroethylene powder, 0.5-10% of surface modified carbon fiber, 0.5-10% of modified nanometer CaCO3, 0.5-10% of nanometer Si2N4 and the balance of polyetheretherketone powder. The tyre is simple in structure, air pressures of the air cavities are equal, the one-way valves are made of the composite material, the probability of tyre burst of a vehicle is reduced, and the service life of the tyre is prolonged.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Penetration prevention safe tyre cyclic chain sheet belt

Owner:HUNAN ZHONGMAN TIRE TECH CO LTD

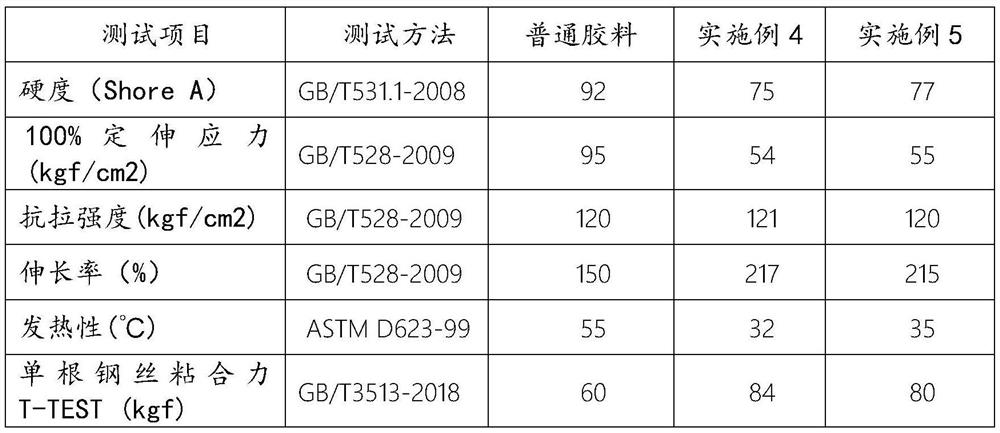

Enhanced anti-puncture and flat-resistant semisolid tyre

The invention discloses an enhanced anti-puncture and flat-resistant semisolid tyre. The enhanced anti-puncture and flat-resistant semisolid tyre structurally comprises an outer tyre, an inner tyre, an air-tight gap, a semisolid inner tyre and ring-shaped rubber pipes, wherein the inner tyre is attached on the inner wall of the outer tyre in an air-tight manner; the air-tight gap is horizontally formed in the middle of the inner tyre; the space between the position above the air-tight gap and the position under a hub is an air chamber of the inner tyre; the semisolid inner tyre is arranged under the air-tight gap and is internally and longitudinally provided with the ring-shaped rubber pipes; and the semisolid inner tyre and the ring-shaped rubber pipes are internally filled with elastic foam materials. Compared with the prior art, the enhanced anti-puncture and flat-resistant semisolid tyre disclosed by the invention has the beneficial effects that the structure is simple, the processing is easy, the puncture and the flat can be prevented, the tyre with air leakage is same as the tyre with air shortage, and normal driving of a vehicle is not influenced at all, so that the safe and durable effects are achieved, and the promotion and use values are good.

Owner:JINAN GAODA INFORMATION TECH

Tire retreading method

InactiveCN103831987AWithout breaking the balanceImprove handling comfortTyresRough surfacePuncture resistance

The invention relates to a method for retreading and recycling a radial all-steel wire waste tire. The method comprises the following steps: grinding the surface of a tire body, namely grinding the steel wire tire to remove the polluted and damaged tire surface and enable the surface to be a threaded rough surface; gluing, namely brushing a mixture of glue paste and glass steel resin onto the tire surface; winding a brand-new glue steel wire tire fabric onto a tire crown and fitting cushion rubber; after gluing the tire surface, fitting matched tread rubber onto the tire crown wound with the steel wire fabric; vulcanizing in a tank, namely feeding the tire with an enhanced belt layer into a vulcanizing tank for vulcanizing. According to the method, the balance of the tire cannot be destroyed and the operating comfortableness can be improved; the puncture resistance and the burst resistance of the tire crown are improved, a framework of the tire body of the tire is kept non-deformed, and the re-retreading probability of the tire is increased; due to the glue steel wire fabric and the thickness of the cushion rubber, the effect of bonding between the tire body and the tire surface is enhanced, the tear resistance of a pattern block is improved, the chunking situation is reduced, and the bearing and buffering capabilities of the tire are improved.

Owner:山东忠诚橡胶有限公司

Manufacturing method for aluminium alloy automobile hub with high performance and big size

InactiveCN101579818BImprove fuel economyImprove riding performanceOther manufacturing equipments/toolsWhole bodyPressure casting

A manufacturing method for an aluminium alloy automobile hub with high performance and big size relates to the mechanical manufacturing method. The semi-solid state thixocasting is used for extruding an alloy automobile spoke with the designed shape and diameter, high mechanical property and fatigue performance on a large scale extruder; aluminium alloy plank stuff is rolled and spun to be a wheelfelloe with the definite shape and diameter; after precision work and amendment, the spoke and the wheel felloe are welded together by inert-gas arc welding or laser-inert-gas arc welding to form a whole body and superficially processed. The aluminium alloy automobile hub has the advantages of light weight, high mechanical property and fatigue performance and the like, can replace a steeliness welding cartwheel used by a commercial vehicle for the moment and a low-pressure casting aluminium alloy cartwheel used by a passenger car, simultaneously increases the fuel economical efficiency and structural strength, is suitable for the cartwheel manufacture of all automobiles and motorcycles and especially suitable for large scale light car wheels and custom car wheels.

Owner:马鸣图 +6

Tire

The invention discloses a tire. A heat dissipation layer is arranged between a casing and a tread, and heat dissipation through holes are formed in the heat dissipation layer and communicated with the two sides of the tire. As the heat dissipation layer is added, heat energy generated during high-speed rotation of the tread is quickly dissipated, so that the wear resistance of the tread is improved; the heat dissipation layer improves the elasticity and the fitting capability of the tire, so that abrasion of the tire and pressure of a shock absorber are reduced on pavement with poor road conditions; owing to the heat dissipation layer, the probability of rupture or air leakage of the tire, caused by sharp objects, is greatly reduced; therefore, the tire is wear-resistant, long in service life, low in burst probability and low in probability of being punctured to leak, and can be maintained through attaching a tread layer to be recycled so as to reduce resource waste.

Owner:安徽皖鹏新能源车辆制造有限公司

Low-temperature-resistant and high-speed-resistant tire self-repairing liquid as well as preparation method and application thereof

The invention discloses a low-temperature-resistant and high-speed-resistant tire self-repairing liquid. The liquid comprises the following components in percentage by weight: 45-55% of natural rubber latex, 1.5-2.5% of a surfactant, 28-32% of an anti-freezing agent, 17.5% of a tackifier and 0.5% of an anti-aging agent. The invention further discloses a corresponding preparation method. The invention further discloses application of the self-service repair liquid, and the self-service repair liquid can adapt to professional car repair, autonomous emergency car repair and tire puncture prevention. The natural latex and the reinforced polymer used in the self-repairing liquid have the same property as the tire, always exist in the tire in a liquid form, cannot be solidified, can be used for a long time at the temperature of minus 40 DEG C to 80 DEG C, are non-corrosive, non-toxic, non-combustible and non-explosive to the tire, have the quality guarantee period as long as 5 years, have no pollution to the environment and are very convenient to use.

Owner:HUANGSHAN BANQIU AUTOMOBILE PARTS CO LTD

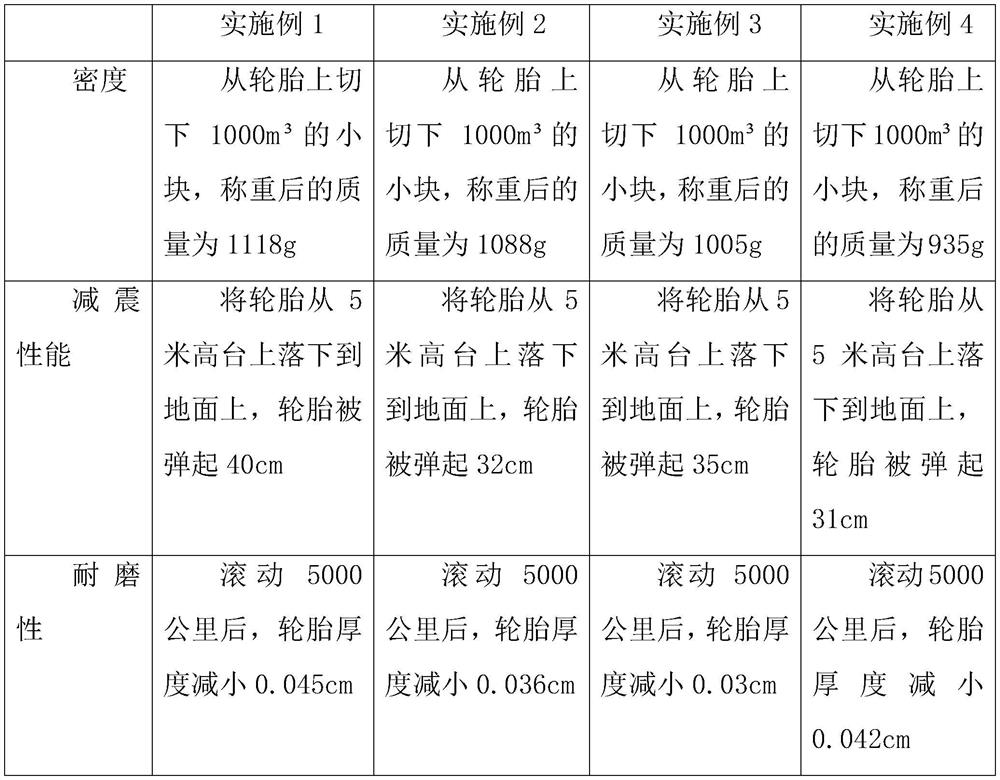

Light shock-absorbing solid tire and preparation method thereof

InactiveCN112480490ALight in massImprove shock absorptionRolling resistance optimizationFiberVulcanization

The invention discloses a light shock-absorbing solid tire and a preparation method thereof. According to the technical scheme, the light shock-absorbing solid tire comprises a main material and an auxiliary material, the main material comprises natural rubber, and the auxiliary material comprises an accelerant, an antioxidant, zinc oxide, sulfur, a foaming agent, a coupling agent, activated carbon fibers, glass fibers, stearic acid, coumarone resin, white carbon black and a foam stabilizer. The light shock-absorbing solid tire and the preparation method thereof have the beneficial effects that the accelerator ZS, the accelerator CZ and the accelerator DM are added according to a proper proportion, so that the tire has good elasticity and toughness and is environment-friendly, the heat conduction performance of the tire is greatly improved by adding the zinc oxide according to a proper proportion into the natural rubber, and the service life of the tire is prolonged. The tire burst probability is reduced in the tire using process; a proper proportion of sulfur is added, so that the vulcanization performance is improved; the glass fibers and the tear-resistant resin are added according to a proper proportion, so that the tire is good in ageing resistance, low in rolling resistance and stable in performance.

Owner:芜湖集拓实心胎有限公司

Anti-puncturing tire of common family car

InactiveCN110626127APrevent tire punctureReduce the chance of a flat tireWith separate inflatable insertsWith multiple inflatable chambersFlat tirePuncturing

The invention discloses an anti-puncturing tire of a common family car. The tire is formed by a grounded solid tire tread and an inflation cavity. The thickness of the grounded solid tire tread is 6 cm, and multiple independent air cavities are formed in the grounded solid tire tread. By means of the anti-puncturing tire, the phenomenon that the tire is punctured can be effectively avoided, the tire cannot leak air even though sharp objects puncture or scratch the tire, and due to the fact that the thickness is increased through the grounded tire tread of the tire, the tire cannot be puncturedgenerally. Meanwhile, the flat tire probability is effectively reduced when the tire runs at a high speed for a long time.

Owner:YANTAI VOCATIONAL COLLEGE

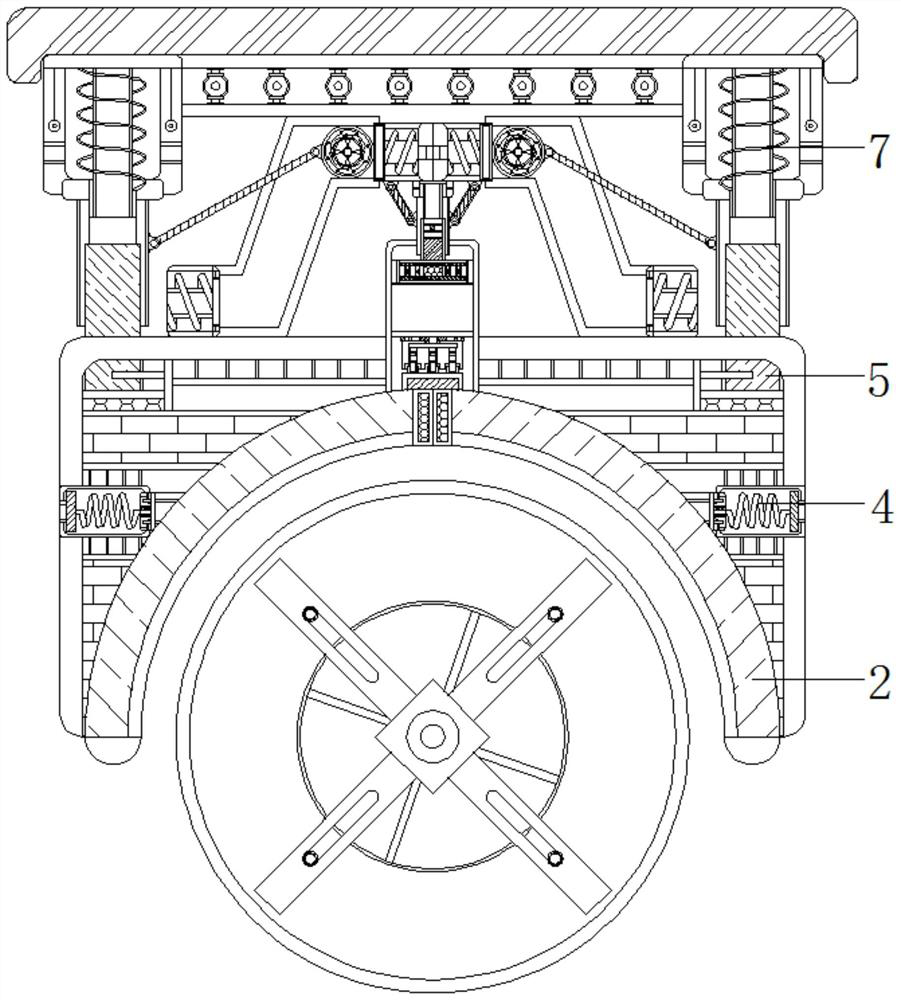

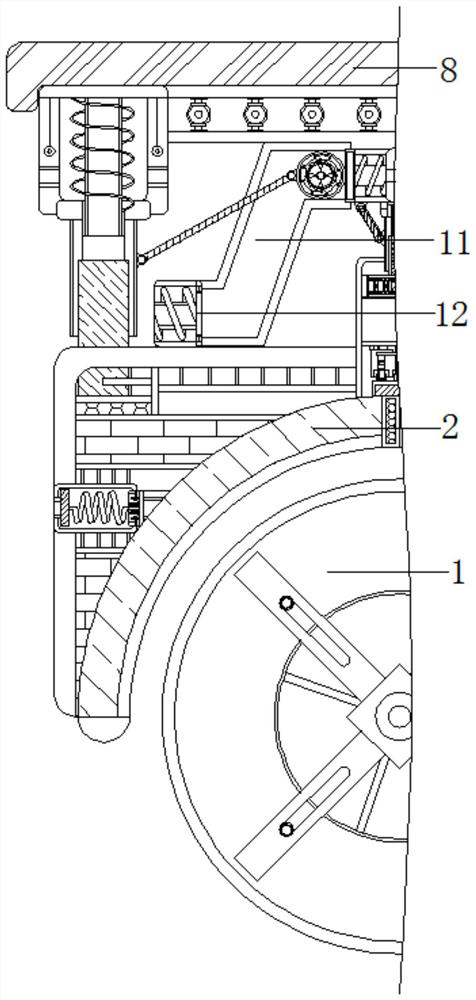

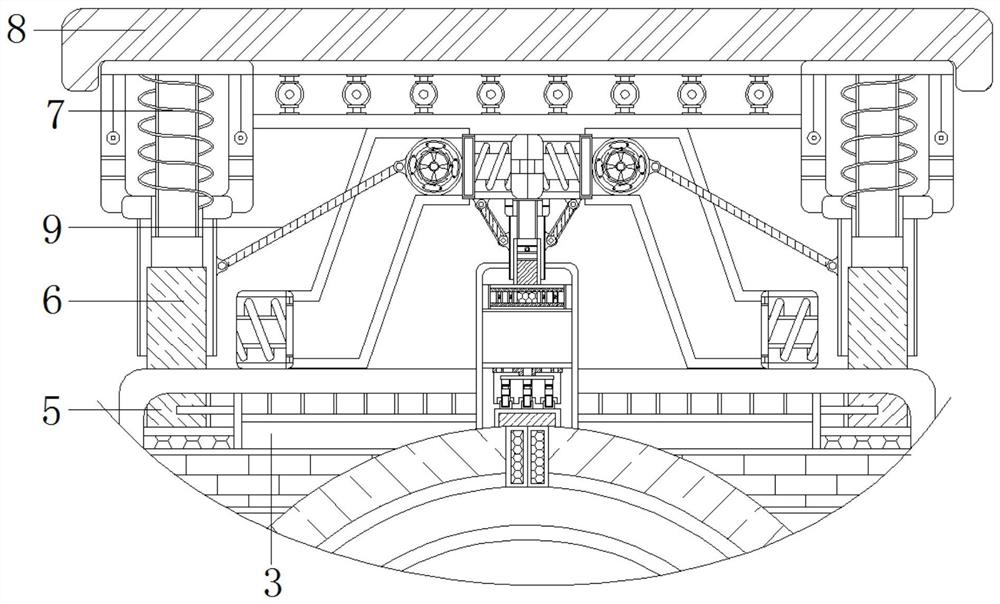

Auxiliary device for reducing dirt adhesiveness and automatically cleaning for automobile mudguard

PendingCN113306631AReduce dirt adhesionReduce adhesionSuperstructure subunitsFenderIndustrial engineering

The invention relates to the technical field of automobile parts, and discloses an auxiliary device for reducing dirt adhesiveness and automatically cleaning for an automobile mudguard, the auxiliary device comprises wheels, a baffle plate is movably connected with the outside of the wheels, a connecting seat is movably connected with the outside of the baffle plate, a vibration spring is movably connected with the bottom of the connecting seat, inserting frames are fixedly connected with the left side and the right side of the connecting seat correspondingly, supporting rods are fixedly connected with the tops of the inserting frames, supporting springs are movably connected with the tops of the supporting rods, and the number of adhesion on the surface of the baffle plate is increased, so that the supporting rods are driven to move after the supporting springs are stretched, and the supporting rods move to pull knocking balls to move in limiting grooves; at the moment, the knocking balls can roll downwards along the limiting grooves to collide with the top of the connecting seat, so that a large shaking force is generated, the adsorption force of dirt is reduced, the dirt is separated from the baffle plate, and the effects of automatically reducing the adhesiveness of the dirt and automatically cleaning the dirt are achieved.

Owner:李港

A multi-chamber run-flat tire with high-performance one-way valve

ActiveCN104589923BImprove stabilityReduce the chance of a flat tireWith separate inflatable insertsWith multiple inflatable chambersFiberCarbon fibers

The invention relates to a multiple-air chamber anti-explosion tyre with high-performance one-way valves and belongs to the technical field of tyres. The tyre comprises a tyre body and a plurality of cavities, wherein the cavities comprise air inflation cavities and a plurality of air storage cavities; a first separation layer is arranged between the air inflation cavity and the air storage cavities; the one-way valve is arranged on the first separation layer; a second separation layer is arranged between two adjacent air storage cavities; the one-way valve comprises a valve body, a piston, a pressing cap and a seal layer between the valve body and the pressing cap; the piston and the seal layer of the one-way valve are made of a composite material; and the composite material comprises the following components: 8-20% of polytetrafluoroethylene powder, 0.5-10% of surface modified carbon fiber, 0.5-10% of modified nanometer CaCO3, 0.5-10% of nanometer Si2N4 and the balance of polyetheretherketone powder. The tyre is simple in structure, air pressures of the air cavities are equal, the one-way valves are made of the composite material, the probability of tyre burst of a vehicle is reduced, and the service life of the tyre is prolonged.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

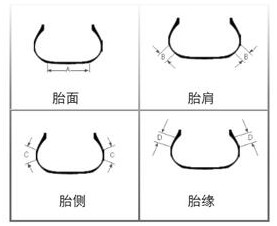

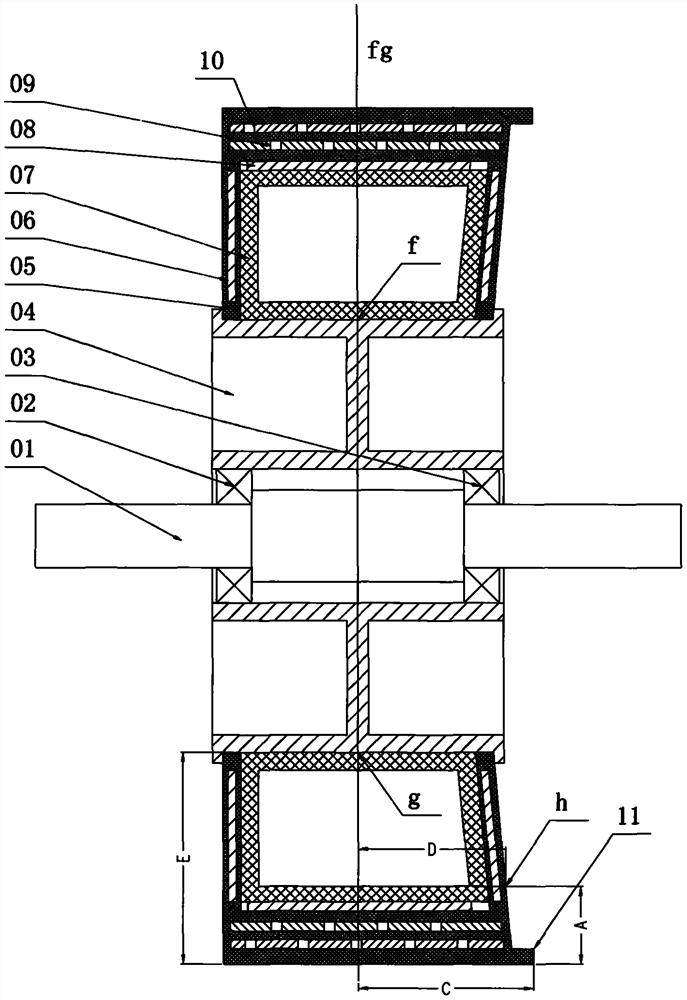

Conveying vehicle and tire

InactiveCN111823788AExtend your lifeSmall squeeze forceTyre sidewallsControl theoryMechanical engineering

The invention provides a conveying vehicle and a tire. According to the tire, a distance D is not larger than a distance C. Due to presence of the structure, when the tire is in contact with a curb, athick tire side close to a tread is in contact with the curb, a weak side wall of the tire is small in deformation, an extrusion force borne by the weak side wall is much smaller, a possibility of tire burst is reduced, service life of the tire is prolonged, and the weak side wall in the middle of the tire does not make contact with the curb as much as possible.

Owner:石强

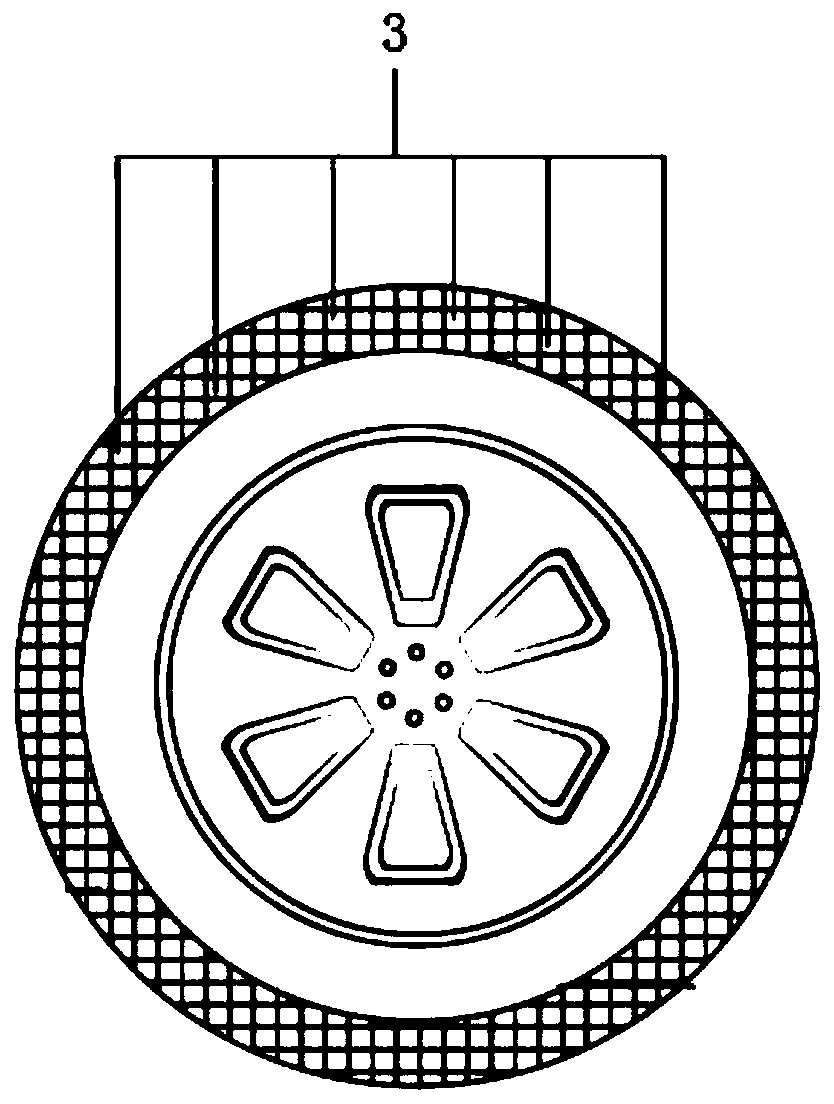

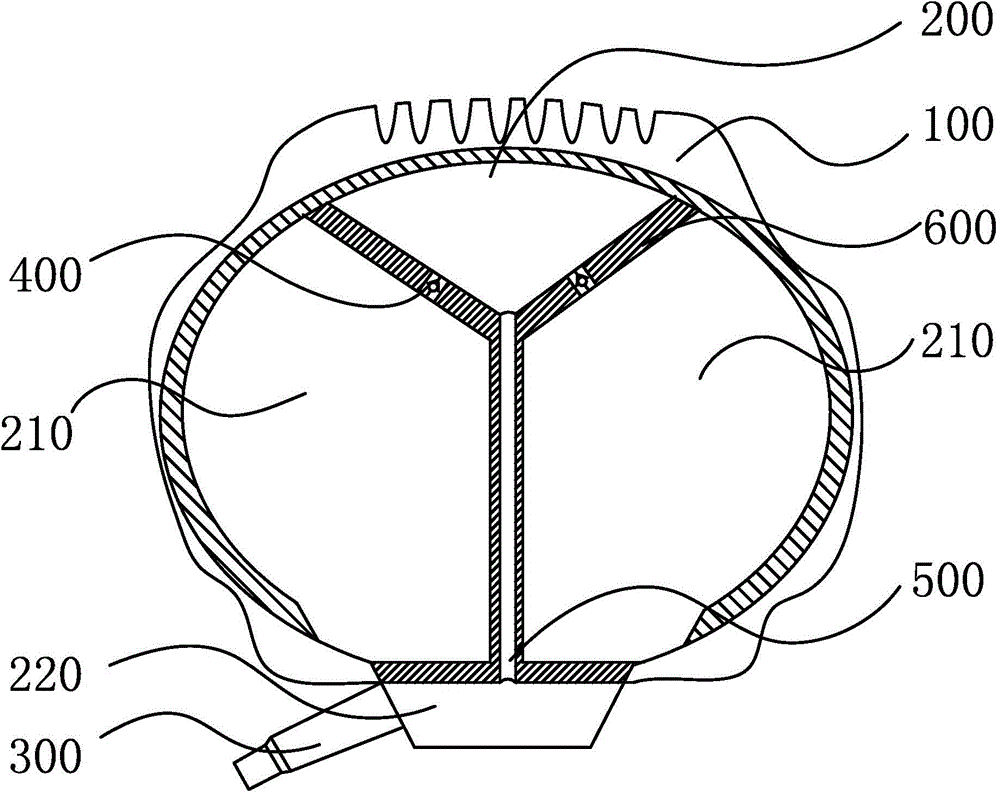

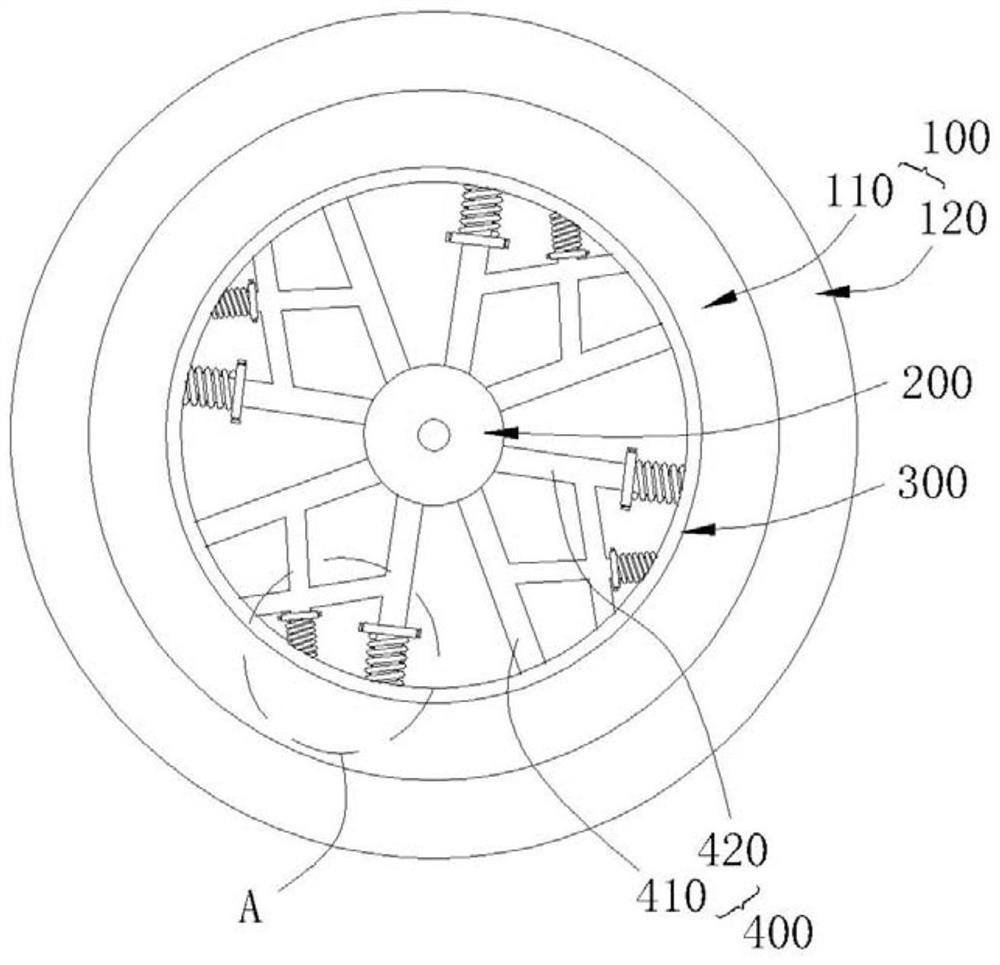

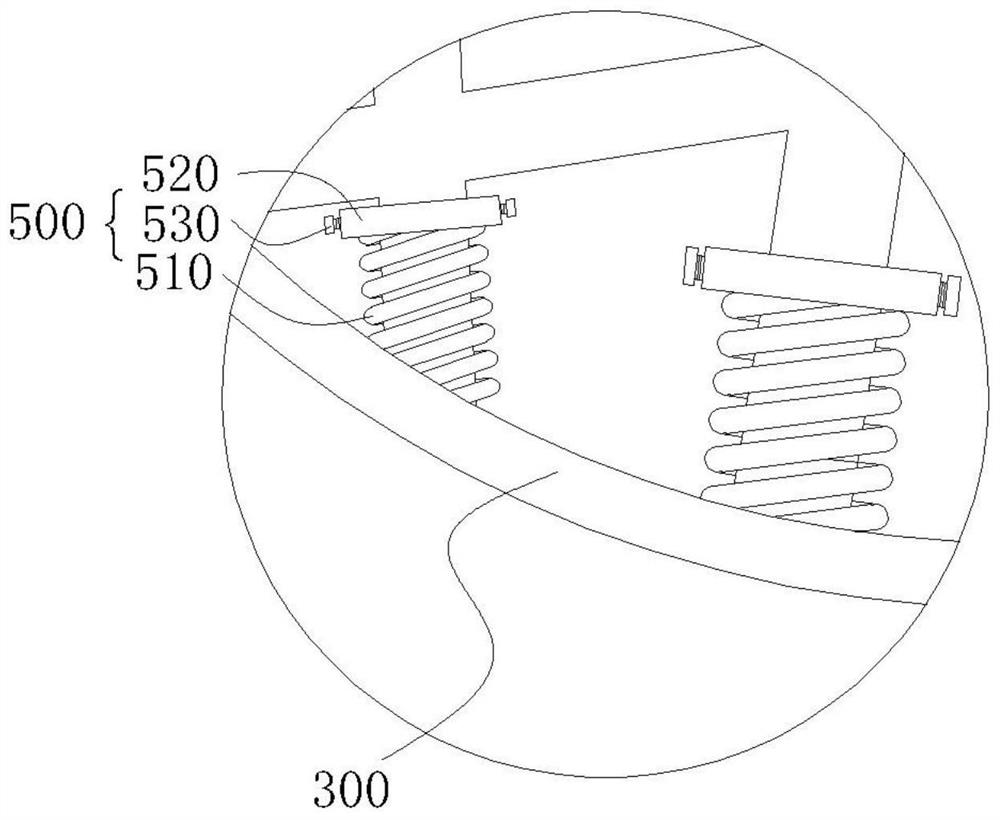

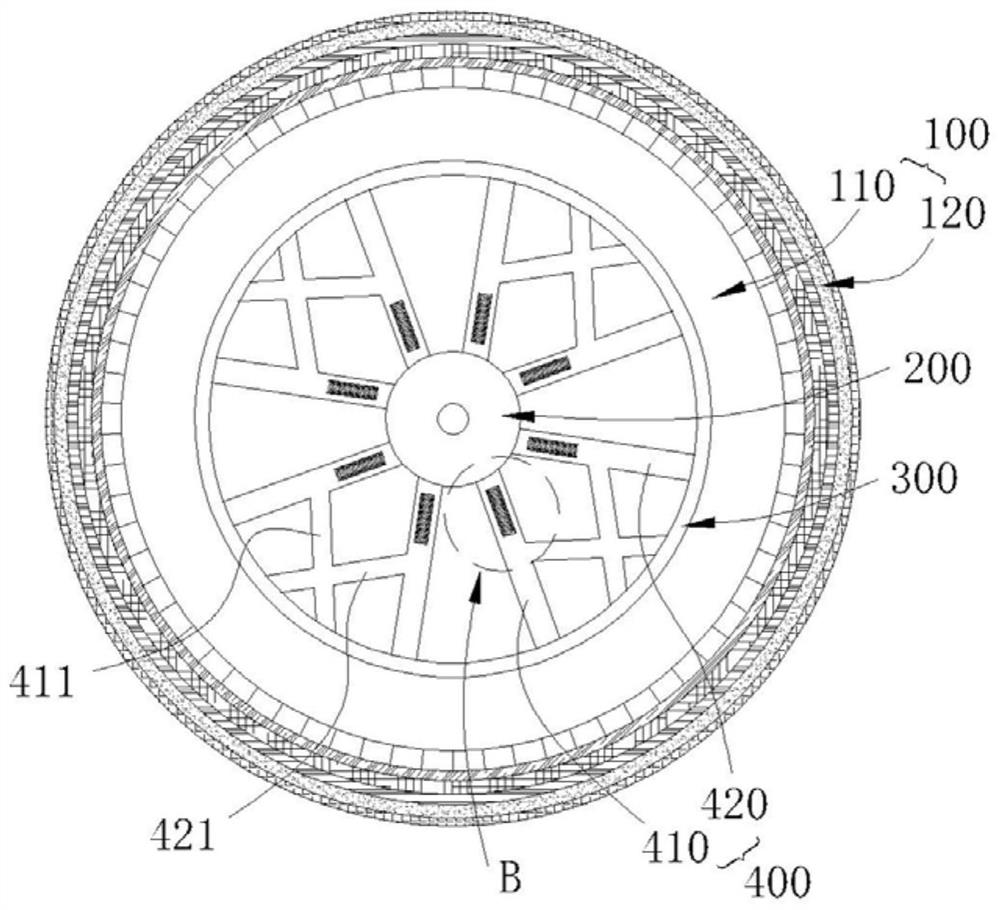

a safety wheel

ActiveCN108482005BReduce the chance of a flat tireNot easy to blow outNon-inflatable tyresInflatable tyresMechanical engineeringTread

The invention discloses a safety wheel. The safety wheel comprises a tire, a hub, a rim and a plurality of spoke groups. The tire comprises an outer tube and an inner tube. The outer tube is arrangedon the outer side of the inner tube. The inner tube is arranged on the outer side of the rim in a sleeving mode. The inner tube is an inflatable tire. The outer tube is an inflatable-free tire. The outer tube comprises a tread layer, a buffer layer, a belt layer, a steel mesh skeleton plastic composite layer and an inner lining layer, wherein the tread layer, the buffer layer, the belt layer, thesteel mesh skeleton plastic composite layer and the inner lining layer are sequentially overlapped. A groove is formed in the outer tube along the circumference. An opening of the groove faces to theinner tube. A honeycomb supporting structure is arranged in the groove. According to the safety wheel, the structures of the spoke groups enable the whole hub and rim to be more stable, the tire is acombination of an inflatable-free solid outer tube and an inflatable hollow inner tube, the inner tube is arranged on the inner side of the outer tube, so that the inflatable tire is not prone to being punctured, and the tire-bursting are not prone to existing, a multi-layer buffer is arranged on the outer tube, the received impact and shock can be absorbed, probability of tire bursting is reduced, and the safety is improved.

Owner:湖北银瑞车轮锻压制造有限公司

Explosion-proof tyre

InactiveCN1282556CReduce the chance of a flat tireExtended service lifeNon-inflatable tyresTraffic accidentRadial projection

Owner:李靖

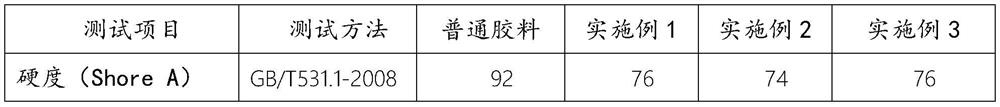

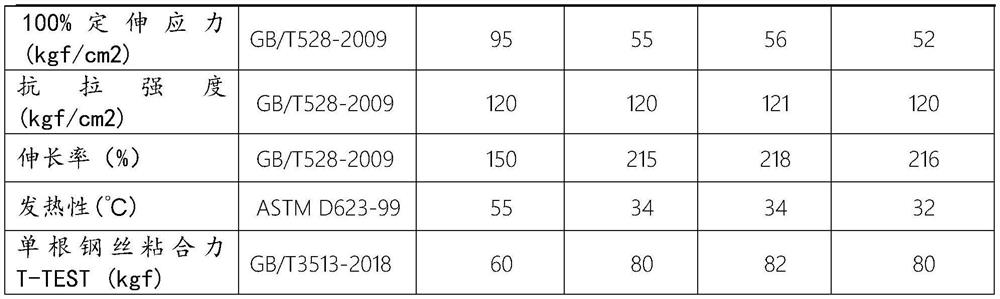

High-performance automobile tire wire rubber and preparation method thereof

ActiveCN111825891AImprove adaptabilityImprove bindingSpecial tyresRolling resistance optimizationTire beadActive agent

The invention discloses high-performance automobile tire wire rubber. The high-performance automobile tire wire rubber comprises (by weight): 20-23% of natural rubber, 17-23% of styrene butadiene rubber SBR 1502, 35-40% of universal furnace black, 7-9% of processing oil, 0.6-1.0% of an active agent ZnO, 3-5% of an active agent SA, 1.5-2.0% of a tackifier WS-27, 1.5-2.0% of a tackifier 1102, 1.5-2.0% of a tackifier HRJ10420, 1.0-3.0% of a vulcanizing agent OT-20, 1.0-2.0% of a vulcanizing agent CLS-B, 0.3-0.8% of an accelerator NS and 0.06-0.1% of a scorch retarder, wherein the sum of the contents of the components is 100%. The invention further provides a preparation method of the high-performance automobile tire wire rubber; in this way, the adaptability of the prepared product to a hub is higher during tire mounting, the shape of a tire bead can be well recovered after the tire bead is stressed, meanwhile, the bonding viscosity of the tire bead and a steel wire is effectively improved, and the service life is greatly prolonged.

Owner:KENDA RUBBER CHINA

Shock-absorbing and bumping-preventing burst-proof low-speed tire

InactiveCN111688412AEnhanced shock absorption and anti-bump performanceIncrease resistanceBicycle tyresNon-inflatable tyresAutomotive engineeringMechanical engineering

The invention discloses a shock-absorbing and bumping-preventing burst-proof low-speed tire, and belongs to the field of tires. The shock-absorbing and bumping-preventing burst-proof low-speed tire comprises: a tire body; an inner cavity, which is an annular cavity formed in the tire body; an anti-pricking cavity, which is a hole cavity formed between the tire tread of the tire body and the innercavity; and a thin layer, which is reserved between the end, away from the anti-pricking cavity, of the inner cavity and the end, making contact with the rim, of the tire body. The anti-pricking cavity is formed between the tire tread of the tire body and the inner cavity, sharp objects are effectively prevented from pricking into the tire body to damage the inner tire, the burst-proof effect is achieved, the inner cavity is formed close to the end, making contact with the rim, of the tire body, and the road holding force of the tire is enhanced while the shock-absorbing and bumping-preventingperformance of the tire is guaranteed; the shock-absorbing and bumping-preventing burst-proof low-speed tire is directly formed through plastication, mold closing, injection, mold opening, secondarymold closing, gas injection, vulcanization, pressure relief, airtight layer preparation and secondary mold opening, and is easy to produce and manufacture.

Owner:ANHUI GVG NEW MATERIAL CO LTD

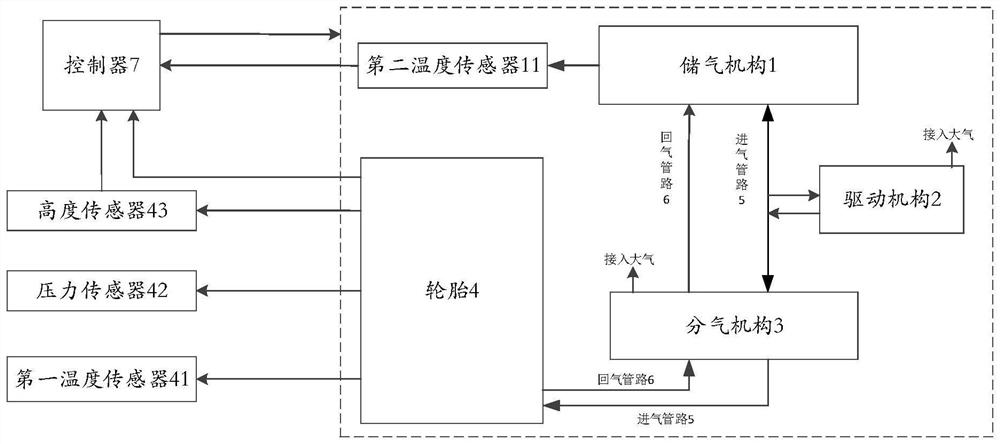

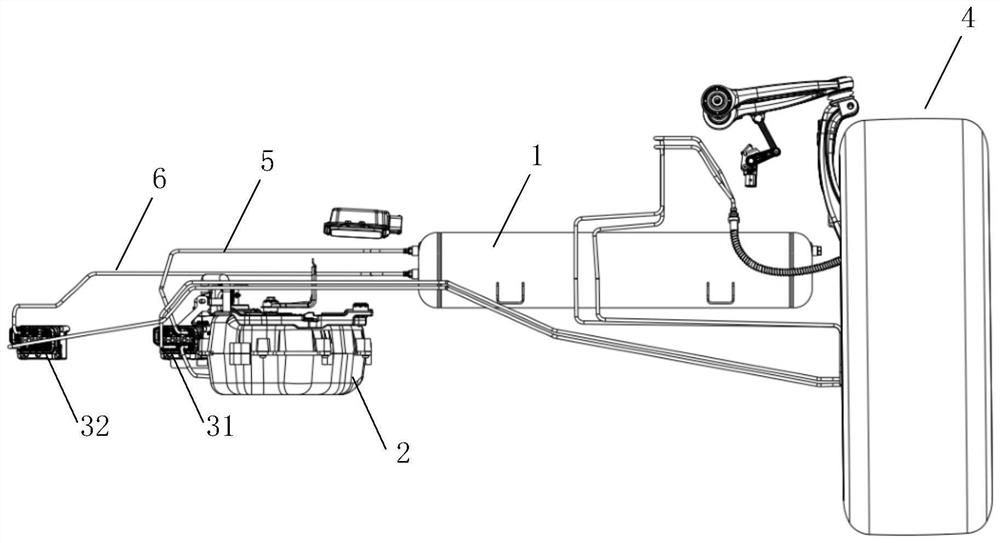

Vehicle and tire pressure adjusting device thereof

ActiveCN114801597AReduce air pressureAvoid safety hazardsTyre measurementsControl theoryMechanical engineering

The invention discloses a vehicle and a tire pressure adjusting device thereof. The adjusting device comprises a driving mechanism, a gas distributing mechanism, a gas storing mechanism, a first temperature sensor, a pressure sensor and a controller. An air outlet of the air storage mechanism, the air distribution mechanism and an air inlet of a tire are sequentially connected in series through an air inlet pipeline, and the driving mechanism is connected between the air storage mechanism and the air distribution mechanism; an air outlet of the tire, the air distribution mechanism and an air inlet of the air storage mechanism are sequentially connected in series through an air return pipeline; the first temperature sensor and the pressure sensor are arranged in the tire; the controller is used for controlling the gas distribution mechanism and the driving mechanism to drive the gas in the tire to circularly flow between the tire and the gas storage mechanism when the temperature of the gas in the tire exceeds a first set temperature; the adjusting device can adjust the air pressure of the tire and the air temperature in the tire in time, the tire burst probability is reduced, and the driving safety is guaranteed.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Four-axle automobile chassis and automobile crane with same

ActiveCN102424001BIncreased overall carrying capacityImprove carrying capacitySteering linkagesFluid steeringEngineeringRolling chassis

The invention discloses a four-axle automobile chassis, which is provided with four axles, a front fixing support leg and a back fixing support leg, wherein the first axle is arranged at the front side of the front fixing support leg, the second axle, and the third axle and the fourth axle are arranged between the front fixing support leg and the back fixing support leg, wherein the first axle and the fourth axle are steering axles, and the second axle and the third axle are driving axles. Preferably, the first axle adopts a mechanical steering device and a steering assistor for driving the steering, and the fourth axle adopts a follow-up assistor for driving the steering. The four-axle automobile chassis provided by the invention can effectively balance the work load of each axle, so the carrying capability of the whole machine is improved, and simultaneously, the transition operation efficiency is further improved. On the basis, the invention also provides a four-axle automobile crane adopting the chassis.

Owner:XUZHOU HEAVY MASCH CO LTD

Method of retreading tyre

InactiveCN101549565BWithout breaking the balanceImprove handling comfortTyresEngineeringMechanical engineering

The invention relates to a method of retreading the old and useless full steel wire tyre by the meridian, comprising the steps as follow: milling the tyre surface, removing the vitiated tyre face and roughening the surface of the steel wire tyre by milling; gluing by coating the plasmagel on surface of the tyre; winding the new glued steel wire curtain cloth on the tread of tyre and adhering withthe middle pad glue; adhering the matched type face glue on the tread of tyre, which wound by the glued steel wire curtain cloth, after the tyre face is adhered with glue; then sulphrizing in the tankthat is sulphrizing the reinforced tread bracing layer into the sulphrizing tank. The invention will not damage the equilibrium of tyre, improve the controlling amenity, increase the anti-piercing and anti-explosion capability of the tread of tyre, prevent the skeleton of tyre from deforming and improve the retreading rate of tyre. The thickness of glue steel wire curtain cloth installed with themiddle pad glue increase the cementation effect between tyre body and the tyre face, improve the anti-tearing capacity of tread block, decrease chunking and improve the bearing and buffer capacity ofthe tyre.

Owner:张乐平

Solid tire with high flexibility and preparation method thereof

The invention relates to a solid tire with high flexibility and a preparation method thereof. According to the technical scheme, the solid tire comprises a main material and an auxiliary material, the main material comprises natural rubber, and the auxiliary material comprises an accelerant, an antioxidant, zinc oxide, sulfur, a foaming agent, a coupling agent, a brightening agent, an anti-fatigue agent, stearic acid, coumarone resin, carbon black and an anti-wear agent. The solid tire with high flexibility and the preparation method have the beneficial effects that the accelerant ZS, the accelerant CZ and the accelerant DM are added according to a proper proportion, so that the tire has good elasticity and toughness and is environment-friendly, and the heat conduction performance of the tire is greatly improved by adding the zinc oxide into the natural rubber according to a proper proportion; the tire burst probability is reduced in the tire using process; a proper proportion of sulfur is added, so that the vulcanization performance is improved; the anti-fatigue agent and the tear-resistant resin are added according to a proper ratio, so that the tire is good in aging resistance, low in rolling resistance and stable in performance.

Owner:芜湖集拓实心胎有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com