Light shock-absorbing solid tire and preparation method thereof

A technology of solid tires and flexibility, applied in the direction of road transportation emission reduction, rolling resistance optimization, etc., can solve the problems of solid tires bulky shock absorption effect, reduce tire quality, etc., to reduce the probability of tire blowout, prolong tire life, good The effect of damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

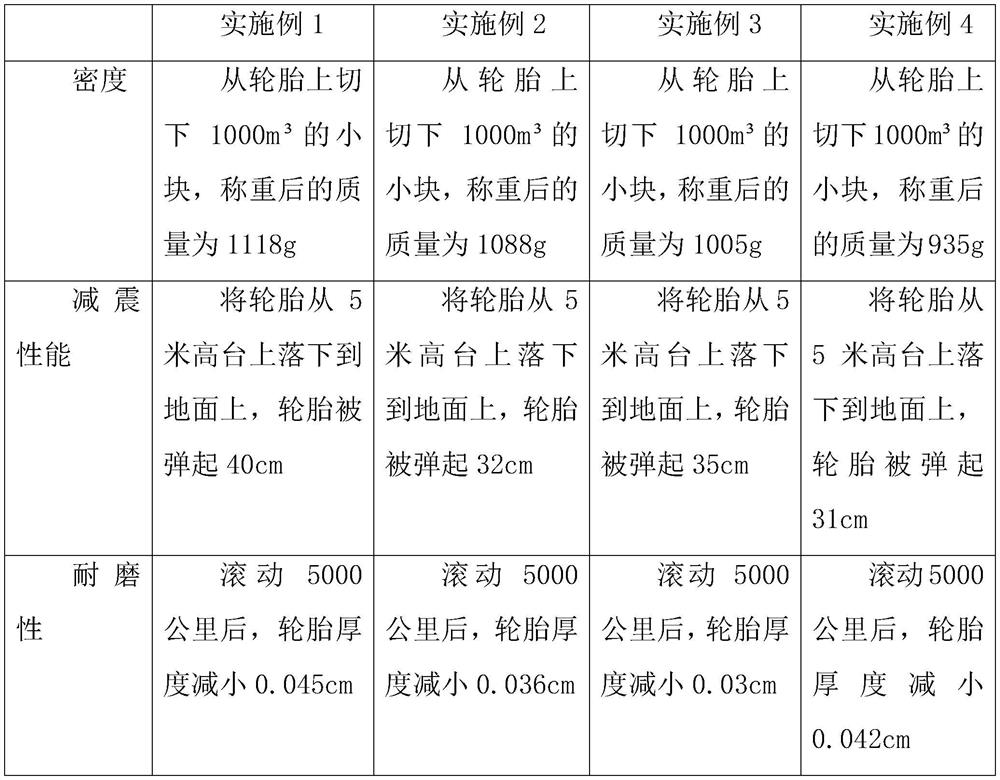

Embodiment 1

[0027] A light-weight shock-absorbing solid tire and a preparation method thereof provided by the invention include main materials and auxiliary materials, the main materials include natural rubber and butadiene rubber, and the auxiliary materials include antioxidants, zinc oxide, coumarone resin, Sulfur, activated carbon fiber, foaming agent, coupling agent, glass fiber, stearic acid, accelerator, white carbon black, foam stabilizer;

[0028] Further, it is prepared from the following raw materials in parts by weight:

[0029] Natural rubber: 90 parts, butadiene rubber: 40 parts, antioxidant: 0.1 parts, zinc oxide: 2 parts, coumarone resin: 1 part, sulfur: 0.9 parts, activated carbon fiber: 2 parts, foaming agent: 3 parts Parts, coupling agent: 0.9 parts, glass fiber: 1 part, stearic acid: 4 parts, accelerator: 0.2 parts, white carbon black: 3.5 parts, foam stabilizer: 3.5 parts;

[0030] Further, the accelerators are accelerator BZ, accelerator D and accelerator NS with a m...

Embodiment 2

[0038] A light-weight shock-absorbing solid tire and a preparation method thereof provided by the invention include main materials and auxiliary materials, the main materials include natural rubber and butadiene rubber, and the auxiliary materials include antioxidants, zinc oxide, coumarone resin, Sulfur, activated carbon fiber, foaming agent, coupling agent, glass fiber, stearic acid, accelerator, white carbon black, foam stabilizer;

[0039] Further, it is prepared from the following raw materials in parts by weight:

[0040] Natural rubber: 100 parts, butadiene rubber: 50 parts, antioxidant: 0.2 parts, zinc oxide: 5 parts, coumarone resin: 1.02 parts, sulfur: 1.0 parts, activated carbon fiber: 3.5 parts, foaming agent: 4 parts Parts, coupling agent: 1.2 parts, glass fiber: 1.8 parts, stearic acid: 5 parts, accelerator: 0.3 parts, white carbon black: 4.5 parts, foam stabilizer: 4.5 parts;

[0041] Further, the accelerators are accelerator BZ, accelerator D and accelerator N...

Embodiment 3

[0049] A light-weight shock-absorbing solid tire and a preparation method thereof provided by the invention include main materials and auxiliary materials, the main materials include natural rubber and butadiene rubber, and the auxiliary materials include antioxidants, zinc oxide, coumarone resin, Sulfur, activated carbon fiber, foaming agent, coupling agent, glass fiber, stearic acid, accelerator, white carbon black, foam stabilizer;

[0050] Further, it is prepared from the following raw materials in parts by weight:

[0051] Natural rubber: 110 parts, butadiene rubber: 60 parts, antioxidant: 0.3 parts, zinc oxide: 8 parts, coumarone resin: 1.1 parts, sulfur: 1.1 parts, activated carbon fiber: 5 parts, blowing agent: 5 parts Parts, coupling agent: 1.5 parts, glass fiber: 2.7 parts, stearic acid: 6 parts, accelerator: 0.4 parts, white carbon black: 5.5 parts, foam stabilizer: 4.5 parts;

[0052] Further, the accelerator is accelerator BZ, accelerator D and accelerator NS wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com