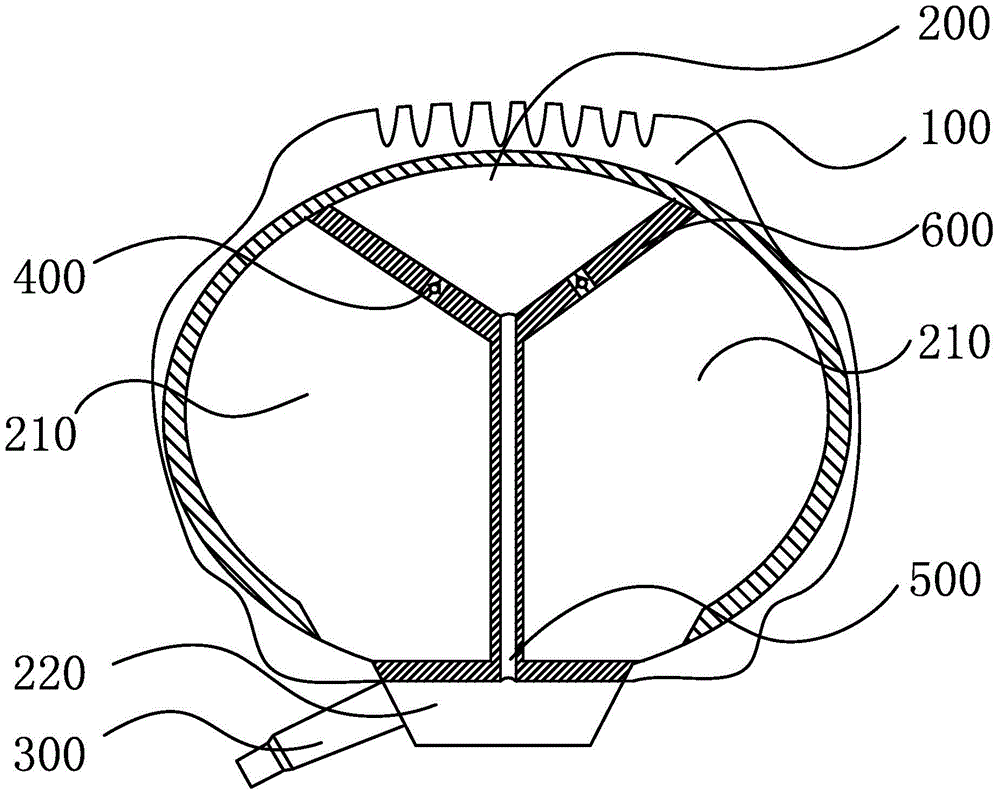

Multiple-air chamber anti-explosion tyre with high-performance one-way valves

A technology of explosion-proof tires and one-way valves, which is applied in the field of tires, can solve the problems of reducing vehicle driving stability, unequal air pressure, and improving vehicle performance, and achieve the effects of reducing the probability of tire blowout, reducing friction and wear, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The piston and the sealing layer of the one-way valve are all made of composite materials, and the components of the composite materials (in mass percentage) are: polytetrafluoroethylene powder: 15%, surface-modified carbon fibers: 8% , modified nano-CaCO 3 : 5%, Nano Si 2 N 4 : 5%, the balance is polyether ether ketone powder.

[0047] Among them, the length of the carbon fiber is 29 mm, and the surface modification can be carried out by the following method: adding the carbon fiber to the compound acidic solution, the molar ratio of the carbon fiber to the compound acidic solution is 1:6, and then under the reaction temperature of 60 ° C Treat for 70 minutes, and dry at 110°C after the treatment is complete. The compound acidic solution is composed of the following components in percentage by weight: 40% of hydrogen peroxide, 60% of sodium sulfate and 10% of sodium formate.

[0048] The nano-CaCO 3 The particle size is 50nm, which can be modified by the following...

Embodiment 2

[0050] The piston and the sealing layer of the one-way valve are all made of composite materials, and the components of the composite materials (in mass percentage) are: polytetrafluoroethylene powder: 12%, surface-modified carbon fiber: 5% , modified nano-CaCO 3 : 8%, Nano Si 2 N 4 : 8%, the balance is polyether ether ketone powder.

[0051] Wherein, the length of the carbon fiber is 40mm, and the surface modification can be carried out by the following method: adding the carbon fiber to the compound acidic solution, the molar ratio of the carbon fiber to the compound acidic solution is 1:6, and then under the reaction temperature of 65°C Treat for 80 minutes, and dry at 105°C after the treatment is complete. The compound acidic solution is composed of the following components in percentage by weight: 35% of hydrogen peroxide, 65% of potassium persulfate and 8% of sodium acetate.

[0052] The nano-CaCO 3 The particle size is 80nm, which can be modified by the following m...

Embodiment 3

[0054] The piston and sealing layer of the one-way valve are all made of composite materials, and the components of the composite materials are composed (by mass percentage): polytetrafluoroethylene powder: 8%, surface-modified carbon fibers: 10% , modified nano-CaCO 3 : 10%, Nano Si 2 N 4 : 1%, the balance is polyether ether ketone powder.

[0055] Wherein, the length of the carbon fiber is 5mm, and the surface modification can be carried out by the following method: adding the carbon fiber to the compound acidic solution, the molar ratio of the carbon fiber to the compound acidic solution is 1:10, and then under the reaction temperature of 50°C Treat for 100 minutes, and dry at 100°C after the treatment is complete. The compound acid solution is composed of the following components in percentage by weight: 50% of hydrogen peroxide, 50% of sodium sulfate and 20% of sodium formate.

[0056] The nano-CaCO 3 The particle size is 25nm, which can be modified by the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com