Tire

A technology for tires and treads, which is applied to tire parts, transportation and packaging, and vehicle parts, etc. It can solve problems such as tire rupture or air leakage, affecting driving safety, and requiring frequent replacement, so as to achieve long service life and low probability of tire blowout. Low, not easy to puncture the effect of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

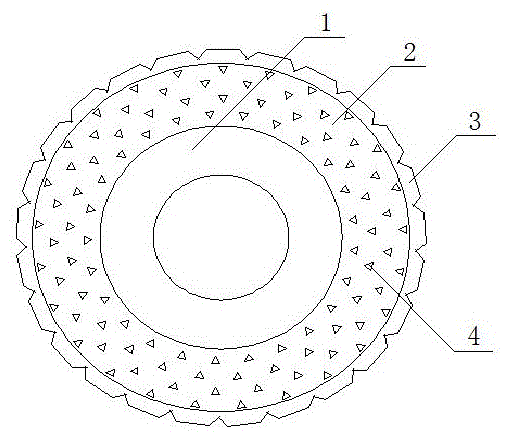

[0014] Such as figure 1 In the shown tire, a heat dissipation layer 2 is provided between the carcass 1 and the tread 3, and the heat dissipation layer 2 is provided with a heat dissipation through hole 4, and the heat dissipation through hole 4 communicates with both sides of the tire.

[0015] The cross-section of the heat dissipation through hole 4 is triangular, circular, elliptical, regular or irregular polygonal. Due to the addition of the heat dissipation layer in the present invention, the heat energy generated by the tread at high speed can be quickly dissipated, and the wear resistance of the tread is increased; and the heat dissipation layer increases the elasticity and bonding ability of the tire, which can be used on roads with poor road conditions. Reduce tire wear and shock absorber pressure; this reduces the rapid degeneration and wear of tires caused by high heat, and effectively protects the shock absorber and prolongs its service life.

[0016] The cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com