Leakproof airbag cavity tire

A technology of preventing air leakage and cavity, which is applied to the reinforcement layer of pneumatic tires, tire inflation valves, tire parts, etc. The effect of light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

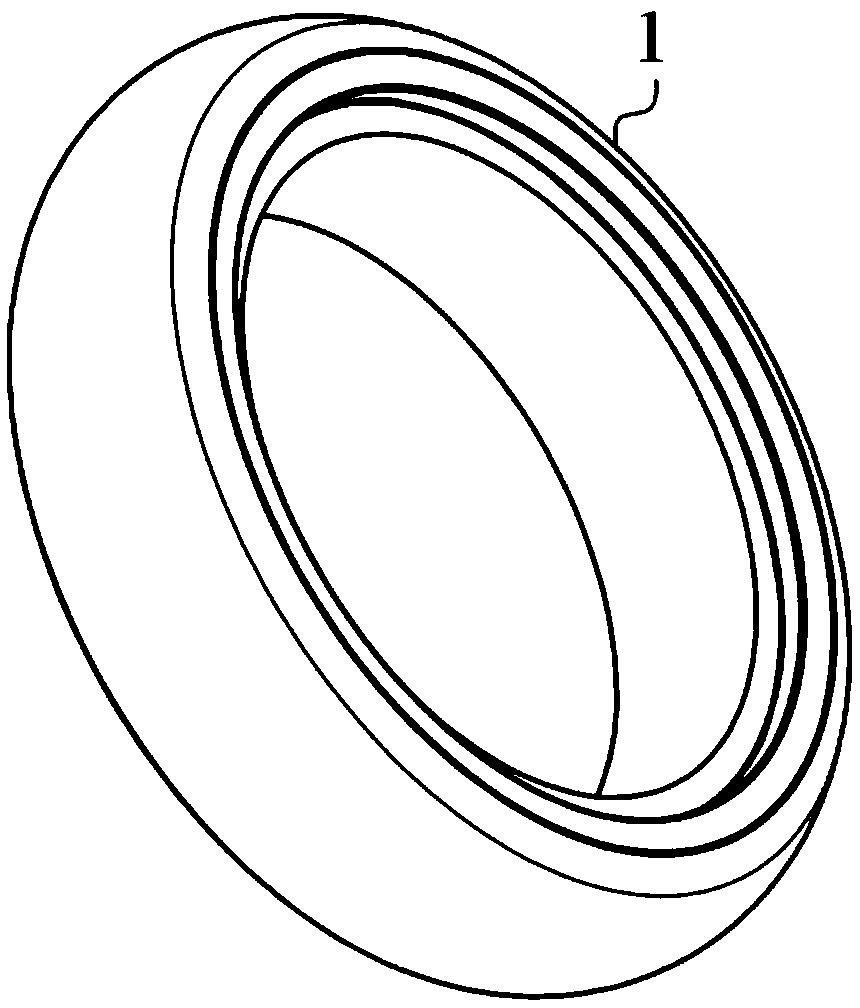

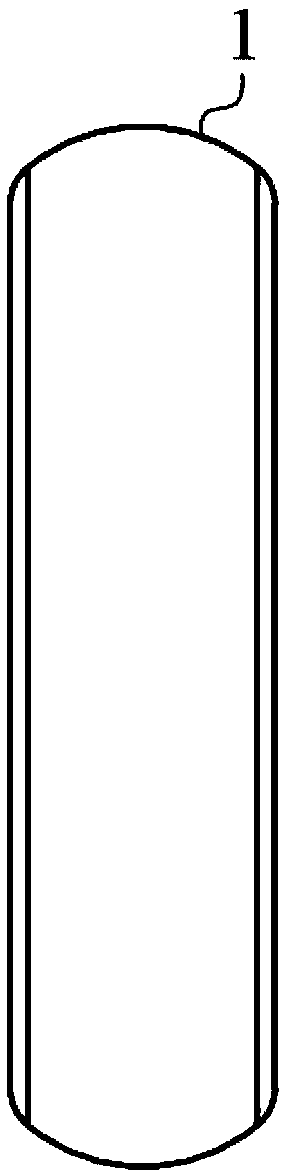

[0052] A kind of anti-leak airbag cavity tire of the present embodiment, as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a carcass 1 and a bladder 10, which is a bladder-shaped cavity opened inside the carcass 1, and adjacent bladders 10 are connected in series through passages.

[0053] In order to effectively solve the problem that the vehicle's center of gravity will be out of control due to tire blowout after air leakage occurs, the present invention improves the shape inside the tire carcass 1. 10 are connected to each other through passages to cover the carcass 1 for a week, and the cystic cavities 10 connected in series constitute the cystic cavity skeleton inside the carcass 1 through the cystic cavity wall, which effectively supports the carcass 1 and strengthens the carcass. The strength of the carcass 1; when the carcass 1 inflated with ordinary tires is punctured, the air pressure in the inner cavity decreases rapidly, causing...

Embodiment 2

[0056] A kind of anti-leakage airbag cavity tire of the present embodiment is further improved on the basis of embodiment 1, such as Figure 7 As shown, a reinforcing hole 12 is opened between the tread of the carcass 1 and the bladder 10 .

[0057] There is a cavity between the cavity 10 and the tread as a reinforcement hole 12, and a reinforced anti-tack layer is formed between the reinforcement hole 12 and the tread. One end of the small head is close to the top of the tread, and the reinforced anti-tack layer formed between the reinforced hole 12 and the big head to the tread can play a very good anti-tack effect. When the car is running, the tread that the tire contacts with the ground is very easy to Punctured by sharp stones and nails, the water drop shape of the reinforced hole 12, and the stress concentration between the small head end and the tread, make it difficult for the tire to puncture the tread when it encounters a sharp object while driving, achieving the ant...

Embodiment 3

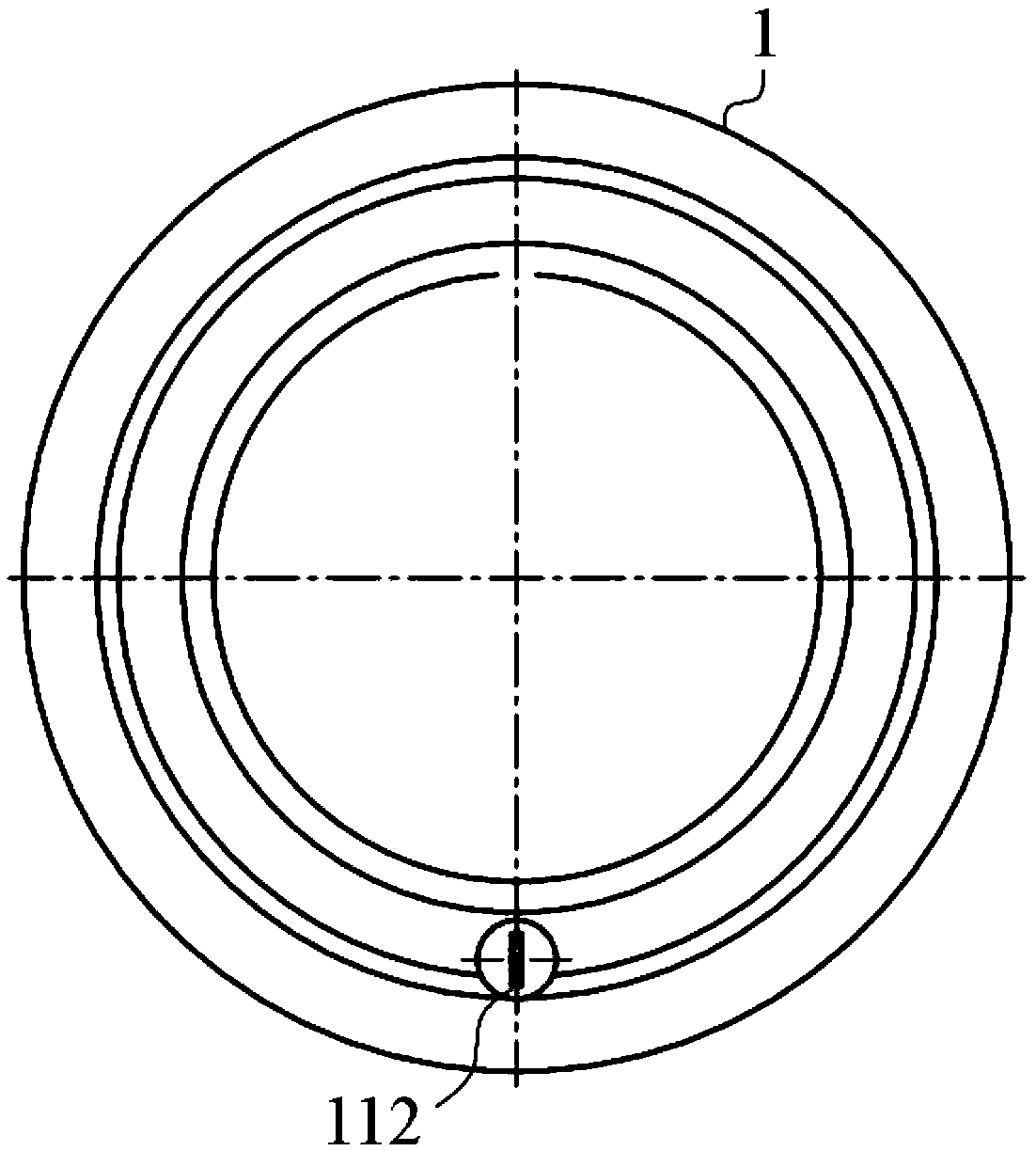

[0059] A kind of anti-leak airbag chamber tire of the present embodiment is further improved on the basis of embodiment 1 or 2, such as image 3 , Figure 4 and Image 6 shown, also includes

[0060] Air valve holes 11, which are opened on the side of the carcass 1, communicate the bladder cavity 10 with the outside of the carcass 1;

[0061] Air valve 110, which is installed in the valve hole 11 and placed on the side of the carcass 1;

[0062] The valve cap 111 is movably connected to the end of the valve 110 to seal the valve 110 .

[0063] A valve hole 11 is provided on the side wall of the carcass 1, and a bladder 10 is communicated with the outside of the carcass. The valve 110 and the valve cap 111 for tire inflation can be placed on the carcass 1 side through the valve hole 11. Now Some valves 110 are mostly installed on the rim of the inner wall of the tire, and a small part are installed in the groove on the side of the rim, which is troublesome to install, requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com