Shock-absorbing and bumping-preventing burst-proof low-speed tire

A low-speed, anti-bump technology, applied in the direction of tires, non-pneumatic tires, tire inflation valves, etc., can solve the problem that low-speed tires are difficult to meet the shock absorption, anti-bump and explosion-proof performance at the same time, and achieve strong grip, good stability and comfort. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

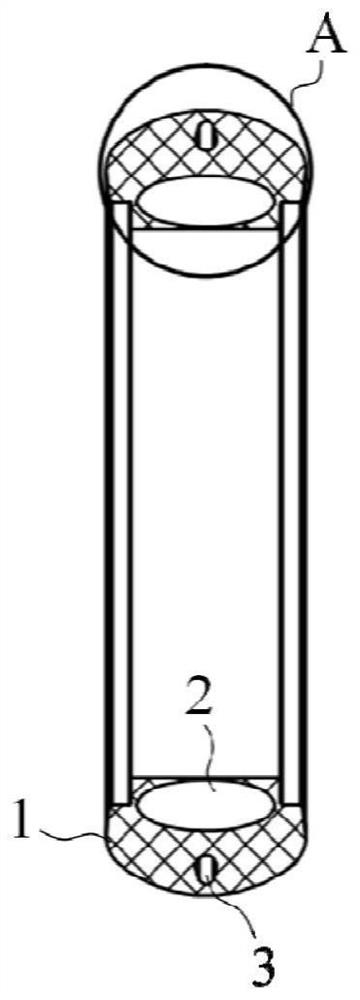

[0069] A kind of shock-absorbing anti-bump anti-explosion low-speed tire of the present embodiment, such as figure 1 shown, including

[0070] Carcass 1;

[0071] Inner cavity 2, which is an annular cavity opened inside the carcass 1;

[0072] Also includes:

[0073] An anti-puncture cavity 3, which is a cavity opened between the tread of the carcass 1 and the inner cavity 2;

[0074] There is a thin layer between the end of the inner cavity 2 away from the anti-puncture cavity 3 and the end of the carcass 1 contacting the rim.

[0075] Tubeless tires and solid tires have large weight and high rolling resistance. When used as low-speed tires on bicycles, electric bicycles and other driving tools, it will make riding more strenuous, increase the power consumption of driving tools, and have poor elasticity and poor shock absorption effect. When the traditional inner tube tires are under-inflated, driving is laborious and power-intensive. When the tire pressure is sufficient,...

Embodiment 2

[0084] The shock-absorbing anti-bump anti-explosion low-speed tire of the present embodiment is applied to the front wheels of two-wheeled vehicles, including

[0085] Carcass 1;

[0086] Inner cavity 2, which is an annular cavity opened inside the carcass 1;

[0087] Also includes:

[0088] An anti-puncture cavity 3, which is a cavity opened between the tread of the carcass 1 and the inner cavity 2;

[0089] There is a thin layer between the end of the inner cavity 2 away from the anti-puncture cavity 3 and the end of the carcass 1 contacting the rim.

[0090] When a two-wheeled vehicle is riding, the center of gravity is concentrated on the rear wheels, which causes the front wheels to float, especially when the front wheels are traditional inner tires, the front wheels have insufficient grip, and it is difficult to control the balance of the vehicle on bumpy roads If you use solid tires or non-pneumatic tires instead, the problem of insufficient grip can be solved, but t...

Embodiment 3

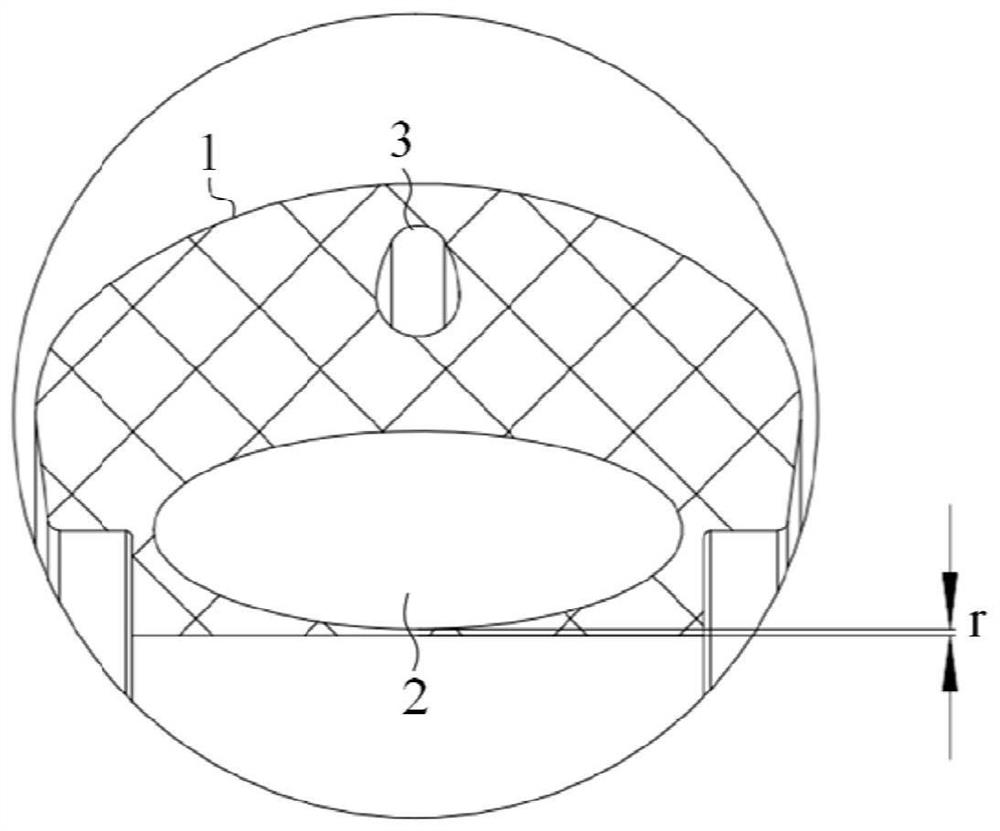

[0093] The shock-absorbing anti-bump anti-explosion low-speed tire of the present embodiment is further improved on the basis of embodiment 1 or 2, such as figure 2 As shown, the distance between the end of the inner cavity 2 away from the anti-puncture cavity 3 and the end of the carcass 1 in contact with the rim is r, 1mm≤r≤5mm.

[0094] The thickness of the thin layer between the end of the inner cavity 2 and the rim should not be too thin or too thick. The cross-section of the inner cavity 2 is approximately circular. It is constantly compressed and rebounded during shock absorption, and the thin layer is prone to cracks due to stress. After the cracks appear, with the use of the tire, the cracks are easy to expand, thereby affecting the service life of the tire, and the appearance of cracks will also affect the inner chamber 2. When the thickness of the thin layer is greater than 5mm, the distance between the inner cavity 2 and the tread is too small, which weakens the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com