Conveying vehicle and tire

A tire and distance technology, applied to tire parts, tire sidewalls, vehicle components, etc., can solve problems such as hidden dangers buried by sidewall tire blowouts, contact with curbs, soft tire damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

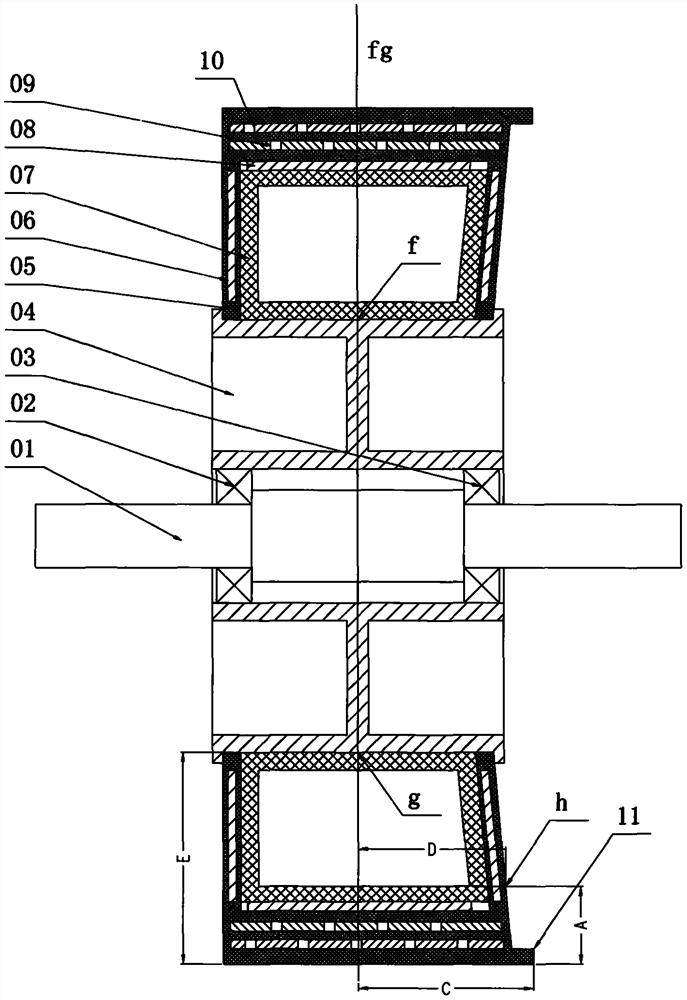

[0023] like Figure 1-Figure 5 , the radial shield is a closed circular tube, the mandrel (01) is fixed with a bearing (02) and a bearing (03), the bearing (02) and the bearing (03) are fixed with a rim (04), and the rim ( 04) There are outer tires (05) and inner tires (07), and radial shields (09) and radial shields (10) are arranged inside the outer tires (05), radial shields (09) and radial shields The blocking piece (10) is two stainless steel tubes. In order to increase the bonding force with the outer tire (05), there are holes on the radial blocking piece (09) and the radial blocking piece (10), and the holes can be filled with glue to enhance bonding Effect, the hole of radial shield (09) and the hole of radial shield (10) are staggered, in order to prevent nail from piercing tire along hole from vertical direction. The thickness of the steel pipe is determined according to the diameter of the steel pipe, which does not affect the physical properties of the tire, such...

Embodiment 2

[0025] like Image 6 , the radial shield is a coil spring-shaped part. Its front view is the same as that of the radial shield of the first embodiment. Better resistance to punctures thanks to multiple layers of protection.

[0026] When the radial barrier is made of metal, its thickness depends on the actual use. If the tire is required to have a wider contact surface, a thinner thickness is required to reduce the influence of the rigidity of the radial barrier. A radial shield with higher hardness can have better performance in preventing punctures.

[0027] The plastic part of the tire may use natural rubber, neoprene, butyl rubber, polyurethane, silicone rubber, nylon, etc. on different occasions.

[0028] The radial blocking member can be made of ordinary hardened steel, such as No. 45 steel.

[0029] If the same metal material is used for the radial shield and the side shield, the radial shield and the side shield can be treated without penetration gaps, such as weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com