Low-temperature-resistant and high-speed-resistant tire self-repairing liquid as well as preparation method and application thereof

A repair fluid and low-temperature-resistant technology, applied in the field of tire repair, can solve problems such as high cost, unbalanced body, poor latex homogeneity, etc., and achieve the effects of reducing the probability of tire blowout, slowing down tire aging, and slowing down rim corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

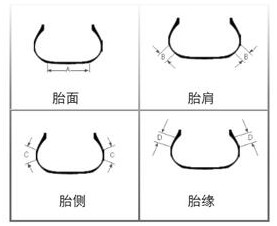

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0038] 1. Formula:

[0039] 1. Raw material introduction:

[0040] A rubber latex: Natural rubber latex (NR) is used as the main component of the tire repair glue, in order to avoid the problem of protein allergy to the user during the use of the glue and the problem of odor caused by protein corruption during storage, and to avoid the problem caused by ammonia In order to solve the problem of corrosion damage to steel cords, ammonia-free natural latex is used. Natural rubber latex is the main component of tire sealant and the main material for hole plugging, so it is the most important raw material.

[0041] B Surfactant: Anionic surfactant is used, which can enha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com