Anti-vibration, buffering and anti-explosion tire

A technology for run-flat tires and tires, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as affecting people's normal work and life, delaying people's travel, and losing stability of vehicles, and increasing shock resistance. and buffering effect, slowing down the phenomenon of tire jumping, and increasing the effect of driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

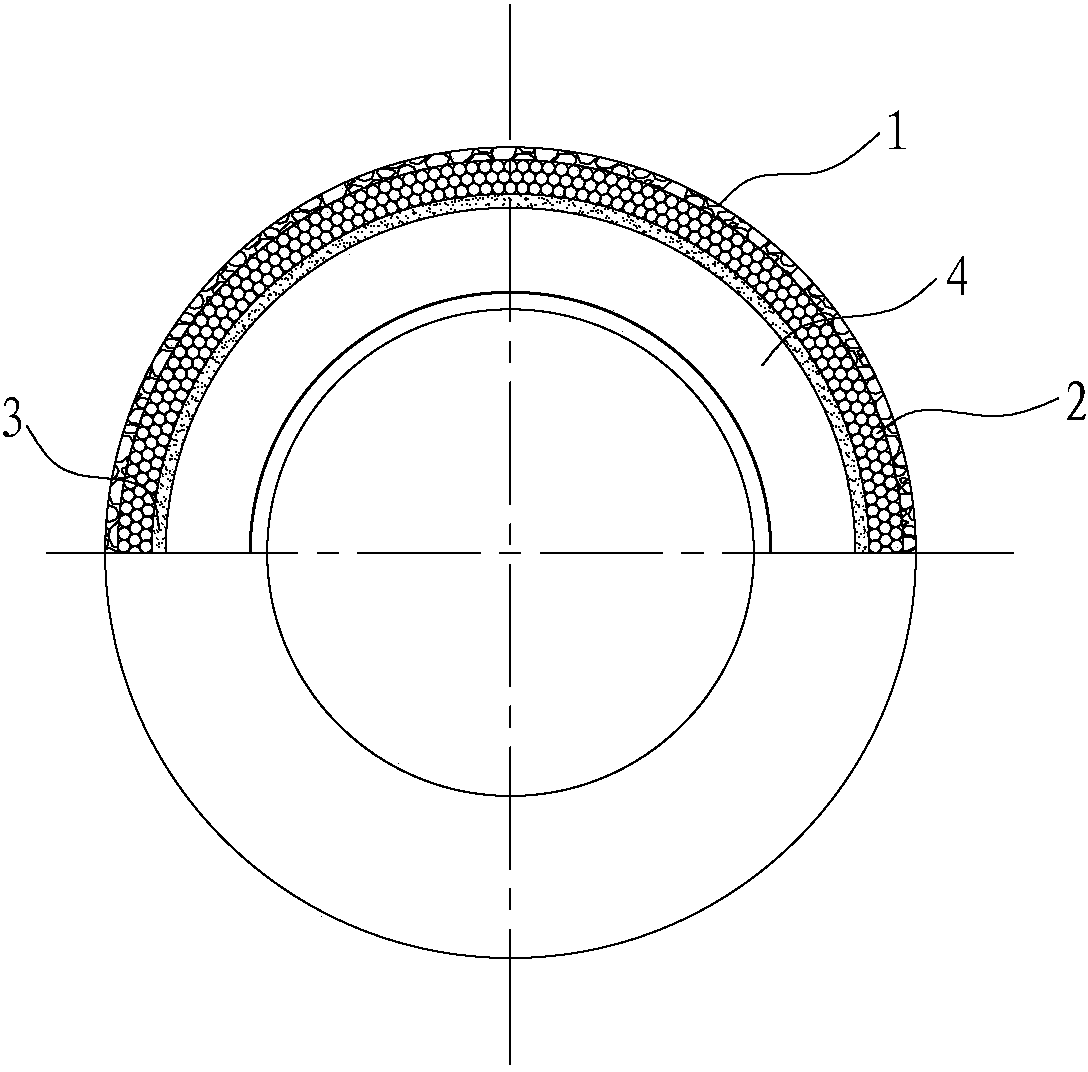

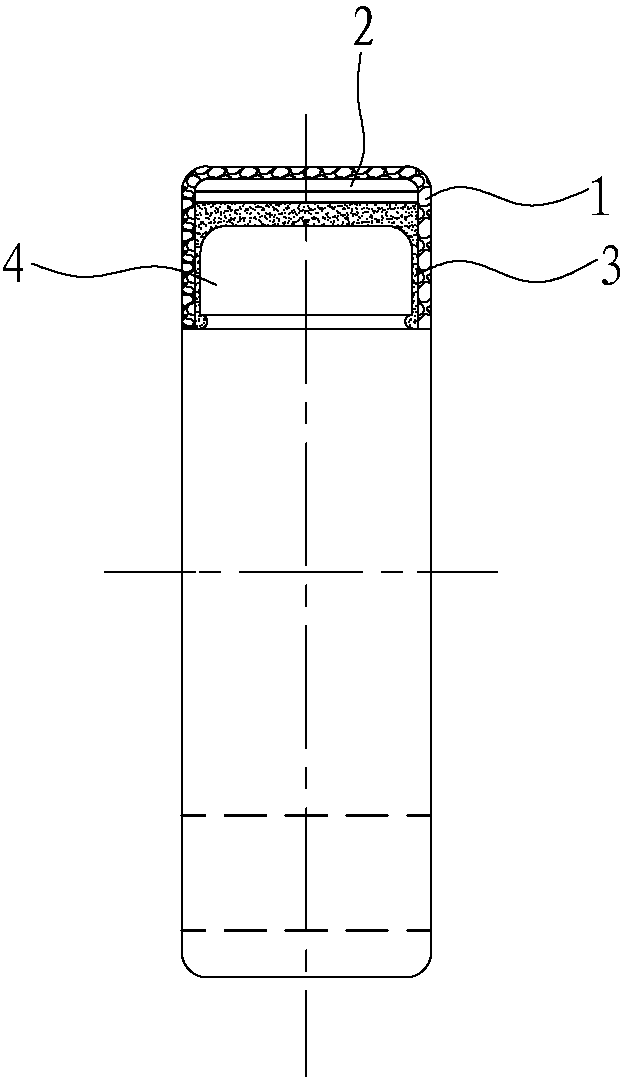

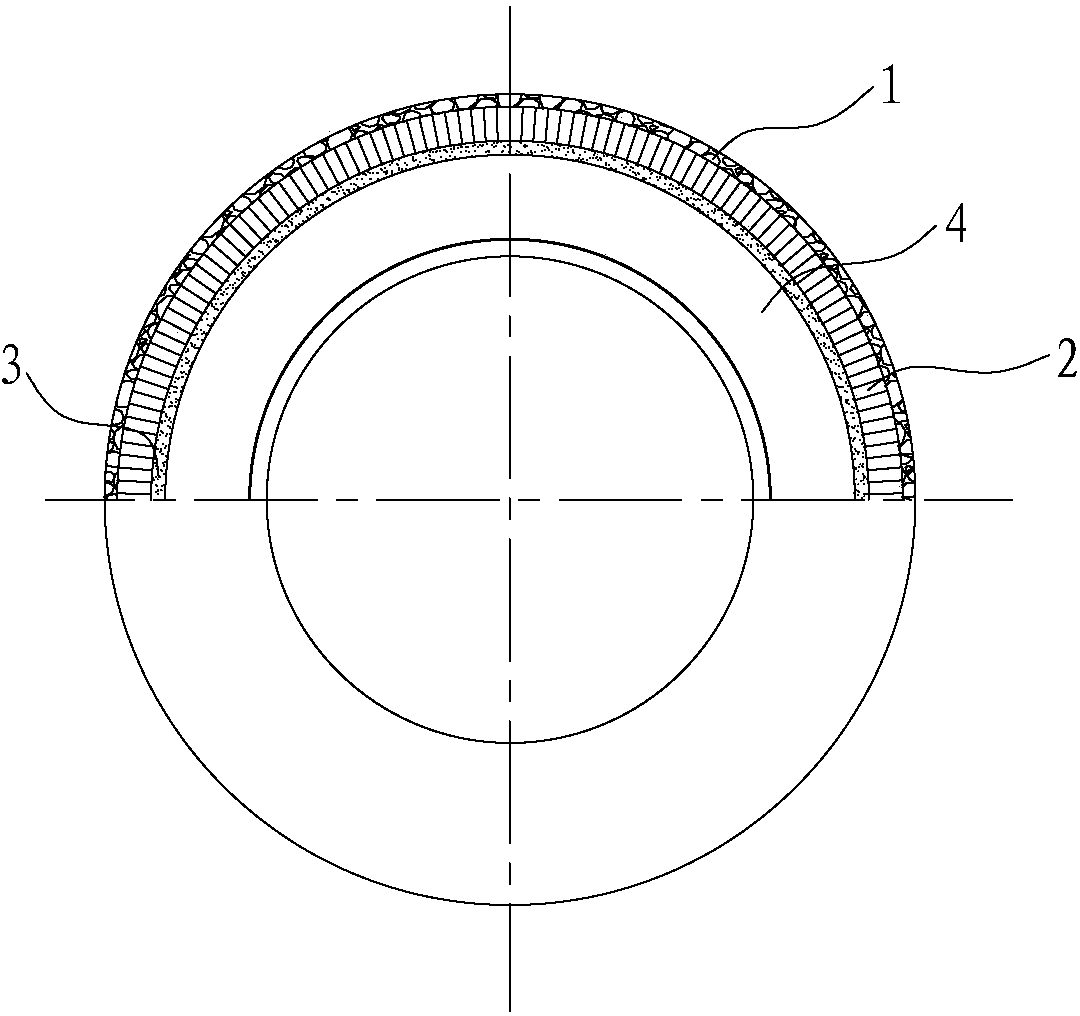

[0024] What the present invention discloses is a kind of anti-vibration buffer explosion-proof tire, such as Figure 1 to Figure 4 Shown is the preferred embodiment of the present invention. The tire is directly installed on the rim (not shown in the figure), and the tire includes an outer tread rubber layer 1, a honeycomb buffer layer 2 and an inner carcass steel wire layer 3, and the honeycomb buffer layer 2 is located on the outer tire Between the surface rubber layer 1 and the inner carcass steel wire layer 3 , within the inner carcass steel wire layer 3 is an air chamber 4 . The honeycomb buffer layer 2 is a structural layer with several honeycomb holes made of elastic buffer material, which can be arranged only on the crown or on the crown and shoulders.

[0025] After the honeycomb buffer layer 2 is added between the outer tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com