Glass plate package tool

A glass plate and utensil technology, which is applied in the fields of packaging, glass plate production and storage during transportation, can solve the problems of difficult recycling of plastic products, immature technical point of view, high manufacturing cost, save wood, meet export requirements, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

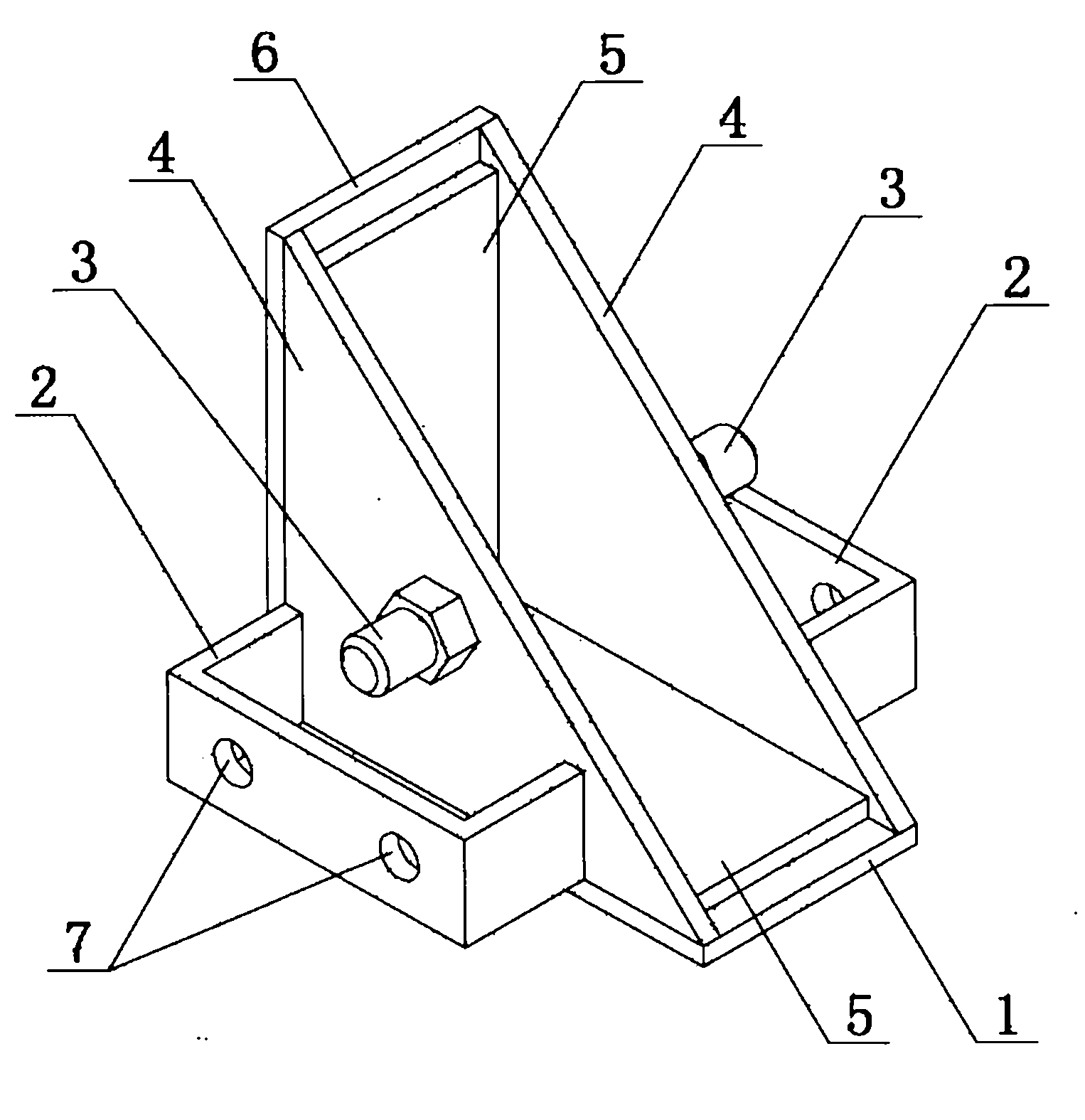

[0030] like figure 1 , Figure 4 Shown is one of the contemplated embodiments of the present invention in which the packaging includes upper and lower corner protectors.

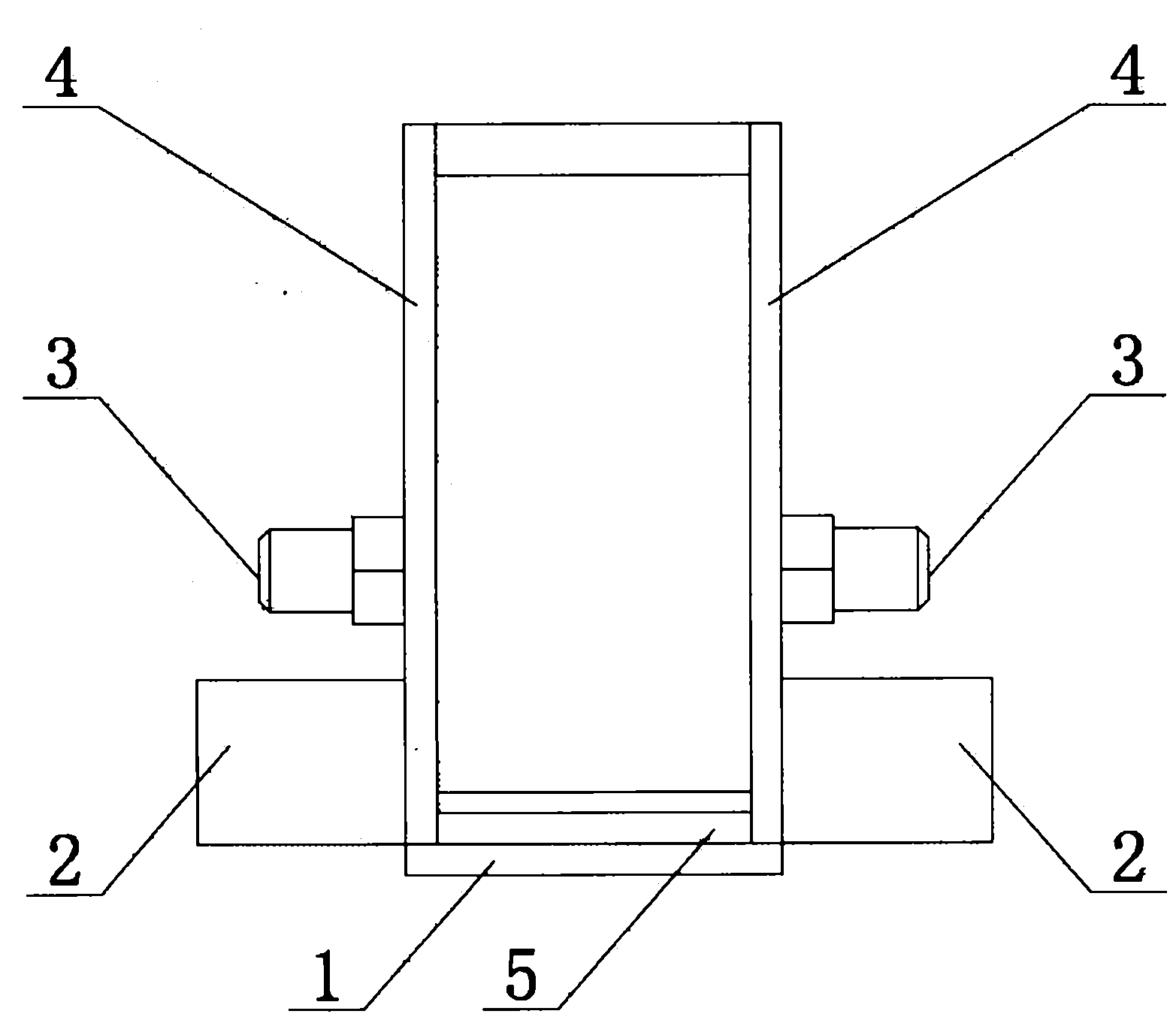

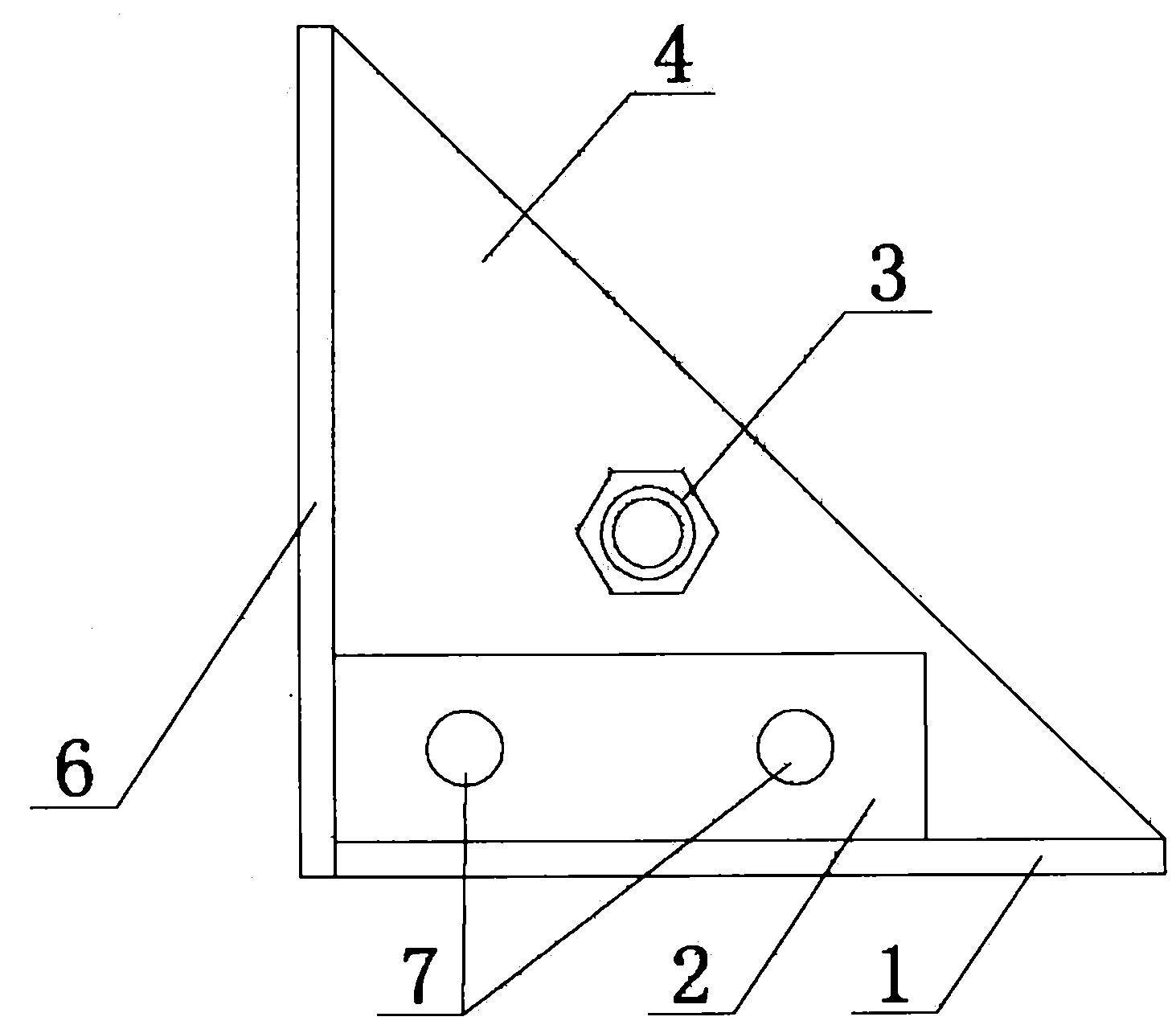

[0031] The structure of the upper corner protection is as follows: figure 1 , figure 2 , image 3 shown.

[0032] like figure 1 , figure 2 , image 3 As shown, the upper corner protector includes a base plate 1, and a back plate 6 is arranged perpendicular to the base plate 1 on one side of the base plate 1, and a three-dimensional right angle between the base plate 1 and the back plate 6 is used as a base to install a The protective plate 4, the protective plate 4 clamps the bottom plate 1 and the back plate 6 to form a glass plate accommodation groove, and the pulling and fixing device 3 protruding from the surface of the protecting plate 4 is installed on the outer surface of the protecting plate 4, the pulling and fixing device 3. During the use of the corner protector, a fixed rope needs to be...

Embodiment 2

[0043] like Figure 10 Shown is the second embodiment of the design of the present invention, different from embodiment 1, in this embodiment the guard plate 4 is a curved plate with a right angle, this design form is the improvement of the structure of the guard plate 4, can The tensile performance of the guard plate 4 is improved, thereby improving the overall mechanical performance of the corner protector.

Embodiment 3

[0045] like Figure 11 , Figure 12Shown is the third embodiment of the design of the present invention, different from embodiment 1, in this embodiment the isolation protection device 2 is a connecting frame with a fixed seat 10, the fixed seat 10 is made of a section of steel pipe, the fixed seat 10 The top of the connecting plate is provided with a connecting plate, with a connecting hole 7 on the connecting plate, and a sealing plate is arranged between the right-angled opposite side of the connecting plate and the guard plate 4, and the sealing plate is formed from the right-angled opposite side of the connecting plate to the guard plate 4 The inclined extension structure, the inclination angle is selected at 45 degrees, and the setting of the sealing plate can prevent the adjacent connecting plate from being stuck in the gap between the connecting plate and the guard plate 4, and the connecting plate is provided with a through hole corresponding to the pulling and fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com