Transportation box and packaging method for solar battery assembly semi-products

A technology of solar cells and packaging methods, which is applied in the directions of transportation and packaging, packaging, and containers for preventing mechanical damage, etc., can solve the problems of high cost, heavy weight, and inconvenient transportation, and achieve safe and convenient transportation, large number of packaging, and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

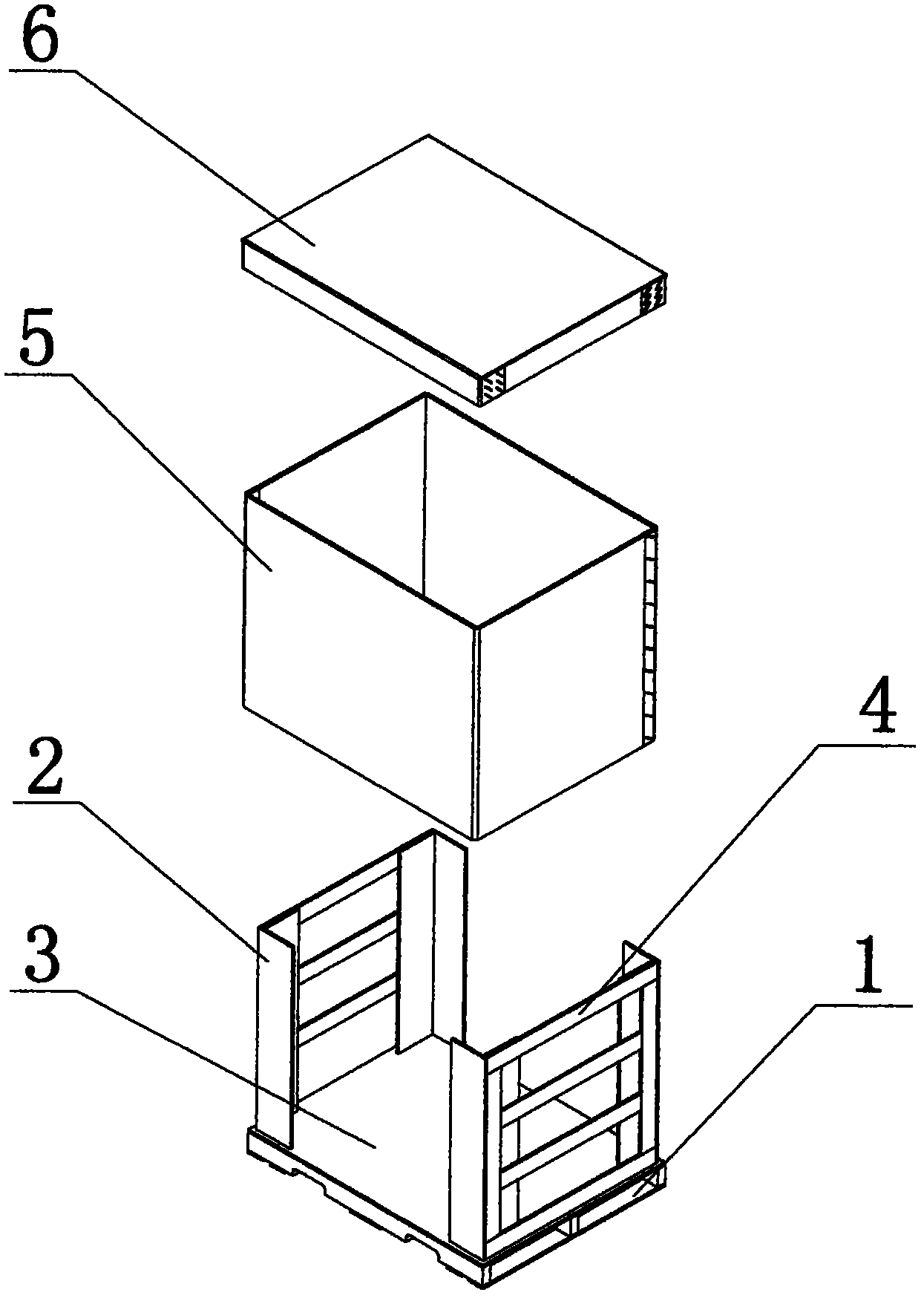

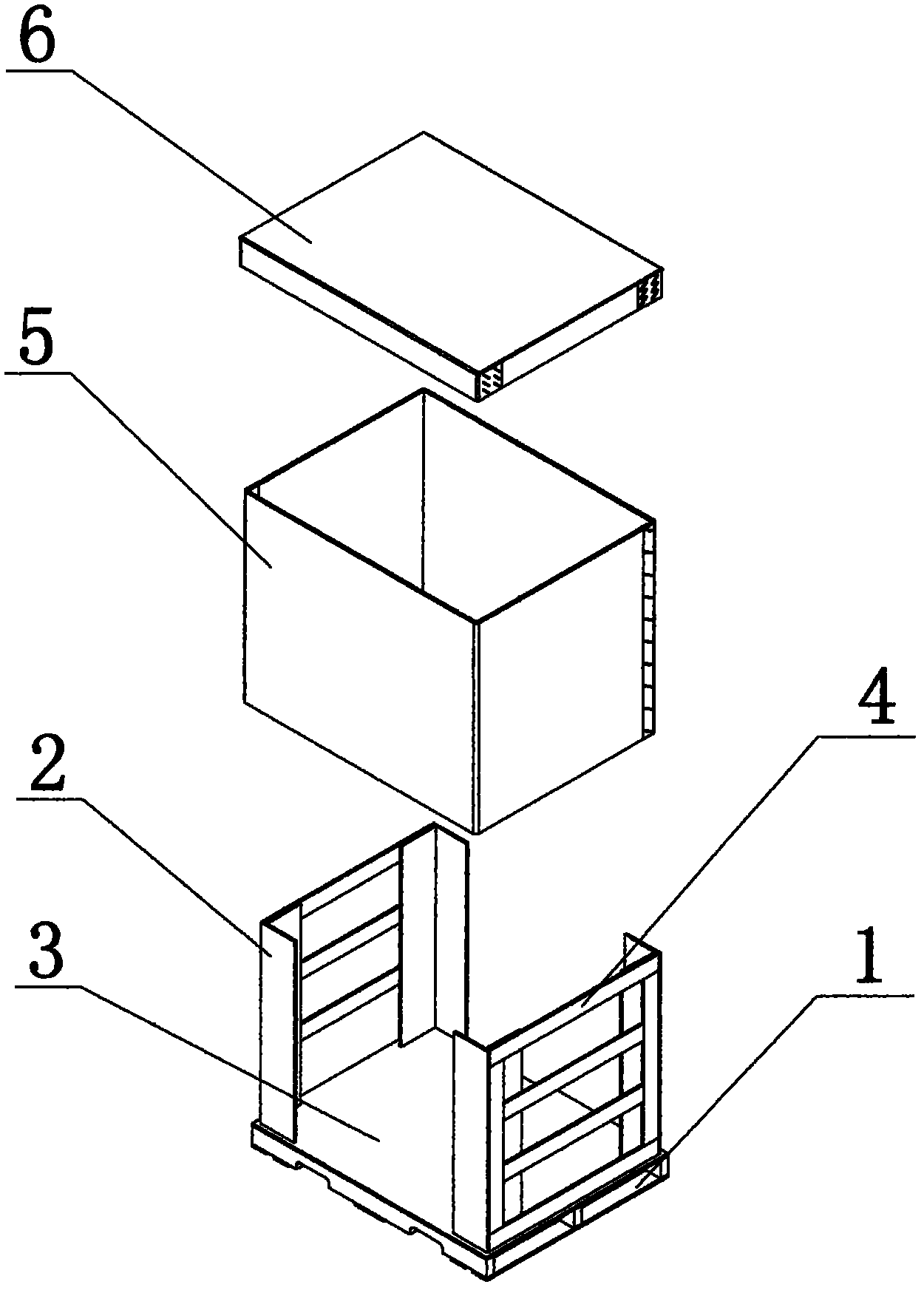

[0017] A transfer box and packaging method for semi-finished solar cell modules. The transfer box is positioned on the pallet 1 during operation. What is important is that the structure of the transfer box includes: positioning at four corners of an integrated chassis 3 The positioning bolt 2, the side plate cover 5, and the top plate 6 are as follows:

[0018] A. Pave the first buffer layer on the chassis 3 of the transfer box;

[0019] B. Place buffer devices on the inside of the four positioning bolts 2;

[0020] C. Place the back sheet glass of the semi-finished solar cell module face down on the first buffer layer;

[0021] D. Spread the middle buffer layer on the components;

[0022] E. Repeat steps C-D until the transfer box is full, and place a second buffer layer on the final semi-finished solar cell module;

[0023] F. Put on the side plate cover 5 of the transfer box and cover the top plate 6;

[0024] G. Bundle the entire transfer box with a strap to complete the packaging of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com