A kind of recycled asphalt concrete and its preparation method

A technology for recycling asphalt and concrete, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of affecting the service life of asphalt pavement, poor temperature stability of asphalt pavement, and easy heat absorption and melting of asphalt pavement. Achieve the effects of increasing anti-rutting deformation and cracking resistance, improving aging resistance and weather resistance, and preventing rutting deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

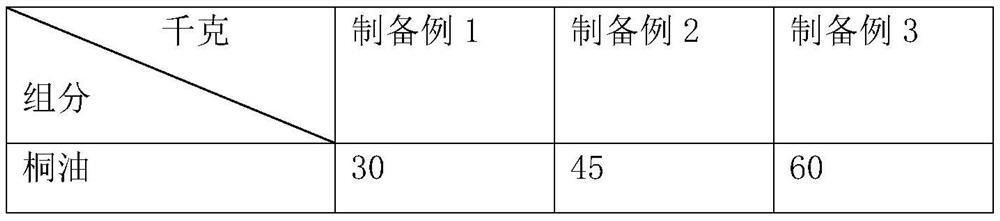

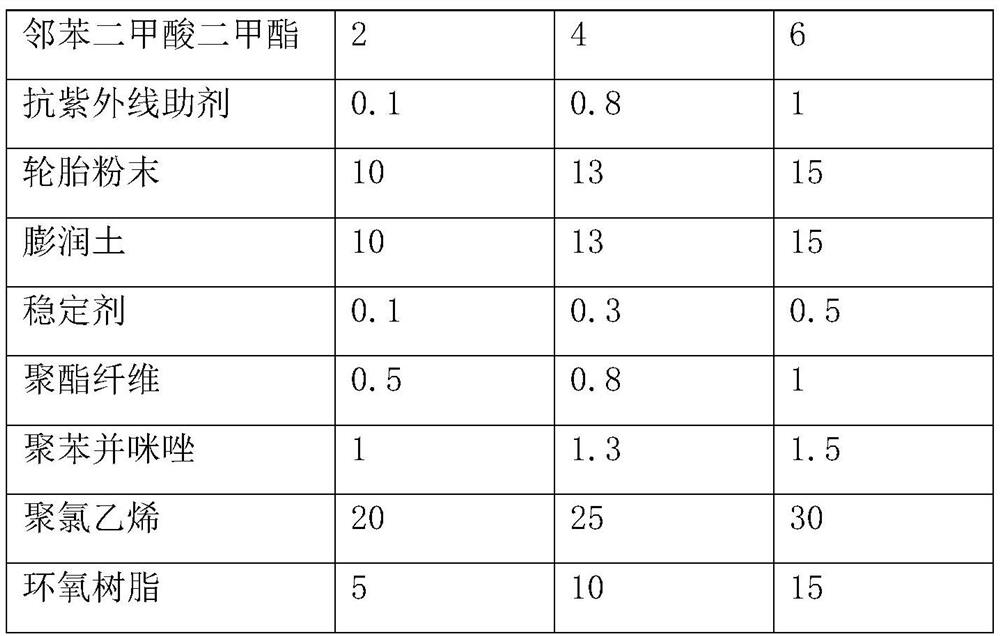

preparation example 1-3

[0039] In the preparation example 1-3, the polyester fiber is selected from the polyester fiber whose article number is 1899 sold by Guangzhou Zhongcheng New Material Technology Co., Ltd., and the ultraviolet absorber is selected from the UV-P type ultraviolet absorber sold by Dongguan Kangjin New Material Technology Co., Ltd. The agent and stabilizer are selected from the XY-620 type stabilizer sold by Weihui Xuyi Plastic Auxiliary Co., Ltd., the tung oil is selected from the lc-0001 type tung oil sold by Shandong Green City Chemical Co., Ltd., and the polybenzimidazole is selected from Suzhou Pinyu Optoelectronics Co., Ltd. The PY5006T polybenzimidazole sold by Technology Co., Ltd., the polyvinyl chloride is selected from the CPM-31 polyvinyl chloride sold by Dongguan Hanzhi Rubber and Plastic Co., Ltd., and the epoxy resin is selected from the E resin sold by Wuxi Qianguang Chemical Raw Materials Co., Ltd. -44 type epoxy resin.

preparation example 1

[0040] Preparation example 1: according to the proportioning in table 1, 0.1kg ultraviolet absorber, 10kg bentonite, 30kg tung oil, 5kg epoxy resin, 0.5kg polyester fiber and 1kg polybenzimidazole are mixed and stirred, and the stirring speed is 1000r / min, stir for 20min, then add 2kg of dimethyl phthalate, 10kg of tire powder, 0.1kg of stabilizer and 20kg of polyvinyl chloride, stir and mix evenly, the rotation speed is 800r / min, stir for 30min, and put in a double Extrude the granular regenerant in the screw extruder, the regenerant particles have a mesh size of 30 mesh, and the tire powder particles have a mesh size of 80 mesh.

[0041] The raw material ratio of regeneration agent in table 1 preparation example 1-3

[0042]

[0043]

preparation example 2

[0044] Preparation example 2: according to the proportioning in table 1, 0.8kg ultraviolet absorber, 13kg bentonite, 45kg tung oil, 10kg epoxy resin, 0.8kg polyester fiber and 1.3kg polybenzimidazole are mixed and stirred, and the stirring speed is 1300r / min, stir for 25min, then add 4kg dimethyl phthalate, 13kg tire powder, 0.3kg stabilizer and 25kg polyvinyl chloride, stir and mix evenly, the speed is 900r / min, stir for 40min, in the temperature of 150℃ Extrude the granular regenerant in the twin-screw extruder, the regenerant particles have a mesh size of 40 mesh, and the tire powder particles have a mesh size of 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com