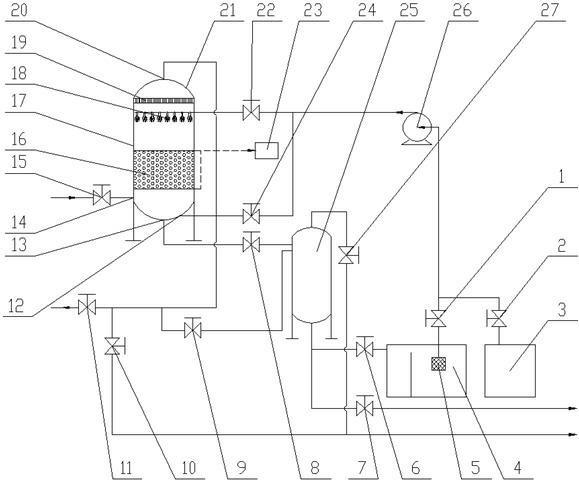

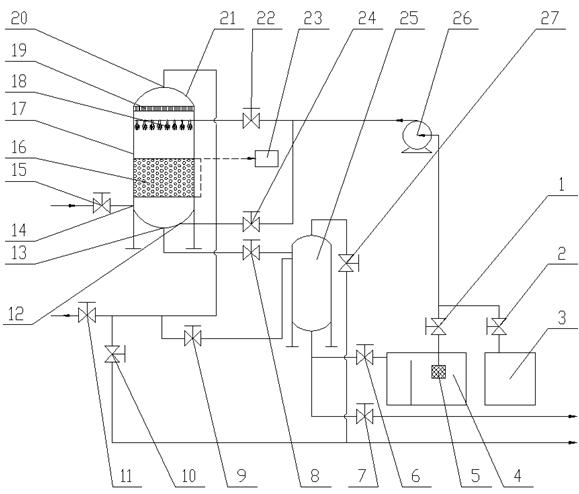

Gas well fine silt ground separation and silt discharge device

A technology of fine silt and ground, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of wear, blockage and erosion of equipment components in gathering and transportation system, and achieve the effect of small impact, high efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] According to the accompanying drawings, a coagulant pool 3 of a gas well fine silt sand ground separation and sand discharge device is equipped with a coagulant; Settling tank 4 is divided into two parts, left and right, and the middle is separated by a partition to form a structure of a connector. The left side of the settling tank 4 is the inlet of the sedimentation liquid, and a filter 5 is arranged on the upper right side of the inside of the settling tank 4. The sand-containing sedimentary liquid is settled by gravity and Under the action of filter 5, it can be recycled as sand washing liquid; the inner lower end of the separator 21 of the fine silt separation device is a settling zone, and the top of the settling zone is a turbulent ball turbulence zone composed of turbulent balls 16 with a diameter of 1 cm. Two sets of nozzles 18 are evenly distributed in the middle and upper cross-section of the interior of 21, mist catcher 19 is arranged above the interior of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com