Pile sinking method for driving large-diameter steel pipe pile in intertidal zone

A steel pipe pile, large diameter technology, applied in sheet pile walls, ships, special-purpose ships, etc., can solve the problems of short operation time, low measurement accuracy, and difficulty in ensuring construction safety, achieve lifting safety, and save engineering costs. , the effect of reducing the requirement of the maximum lifting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

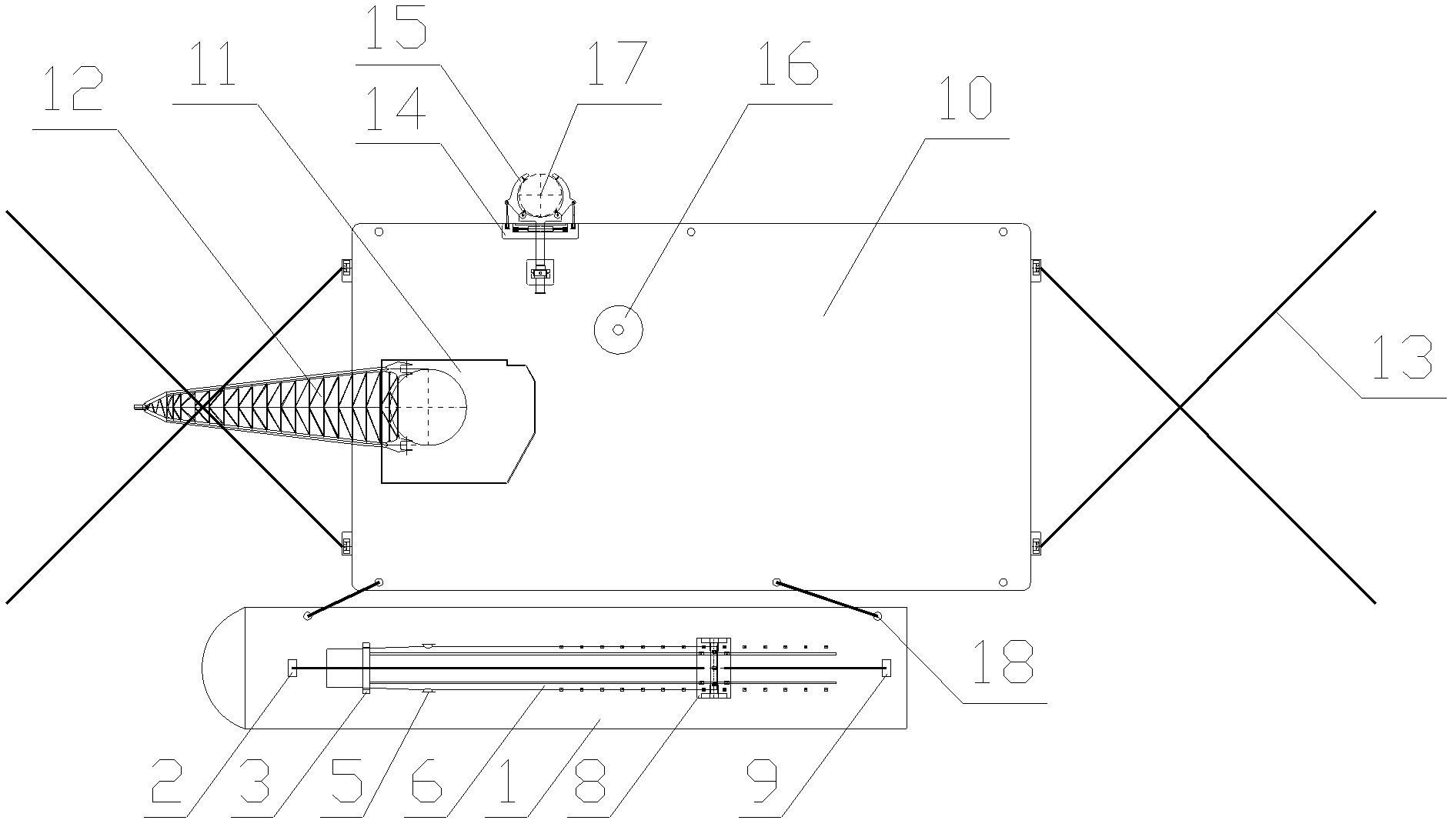

[0039] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a pile sinking method for driving large-diameter steel pipe piles in the intertidal zone, using a special ship for large-diameter steel pipe pile transportation and auxiliary pile-hanging construction to cooperate with a full-turn crane ship with a beach function to realize large-diameter The specific steps of steel pipe pile sinking operation are as follows:

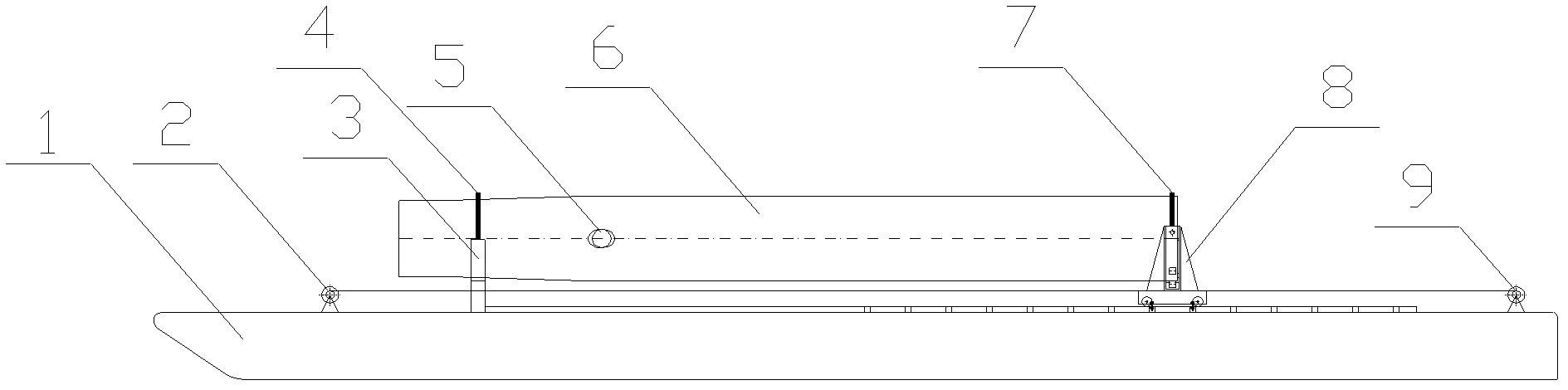

[0040] Step 1: After the steel pipe piles are processed and manufactured, they will be hoisted at the wharf to the special ship for large-diameter steel pipe pile transportation and auxiliary pile lifting construction, and transported to the construction site, such as figure 1 shown.

[0041] Step 2: Follow the attached figure 2 In the manner shown, when the tidal level in the intertidal zone meets the draft requirements o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com