Anti-pulling universal rolling supporting base

A technology of rolling bearings and bearings, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of excessive bearing area and insufficient vertical bearing capacity, achieve clear and reasonable force transmission, facilitate manufacture and installation, and improve The effect of the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

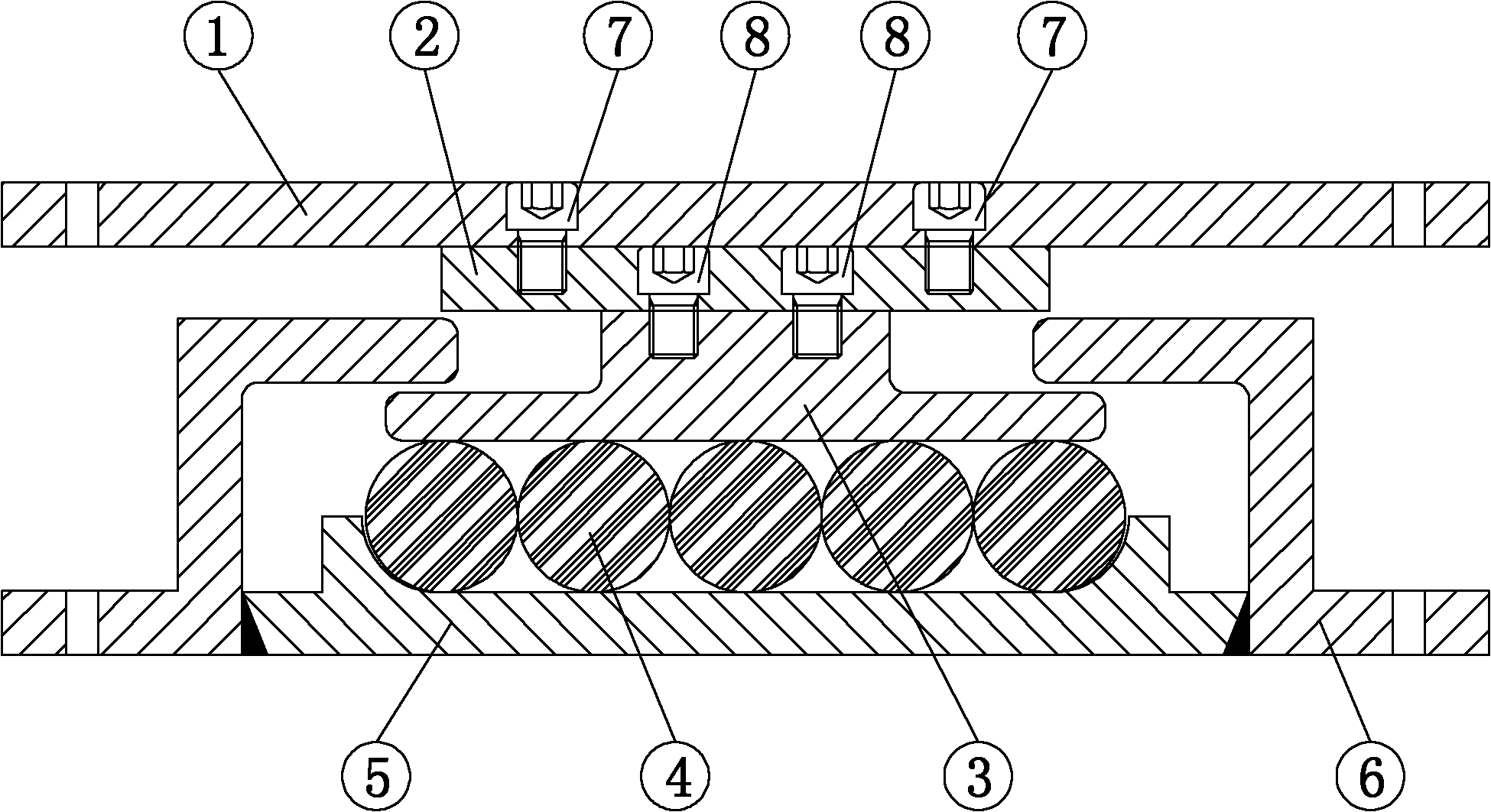

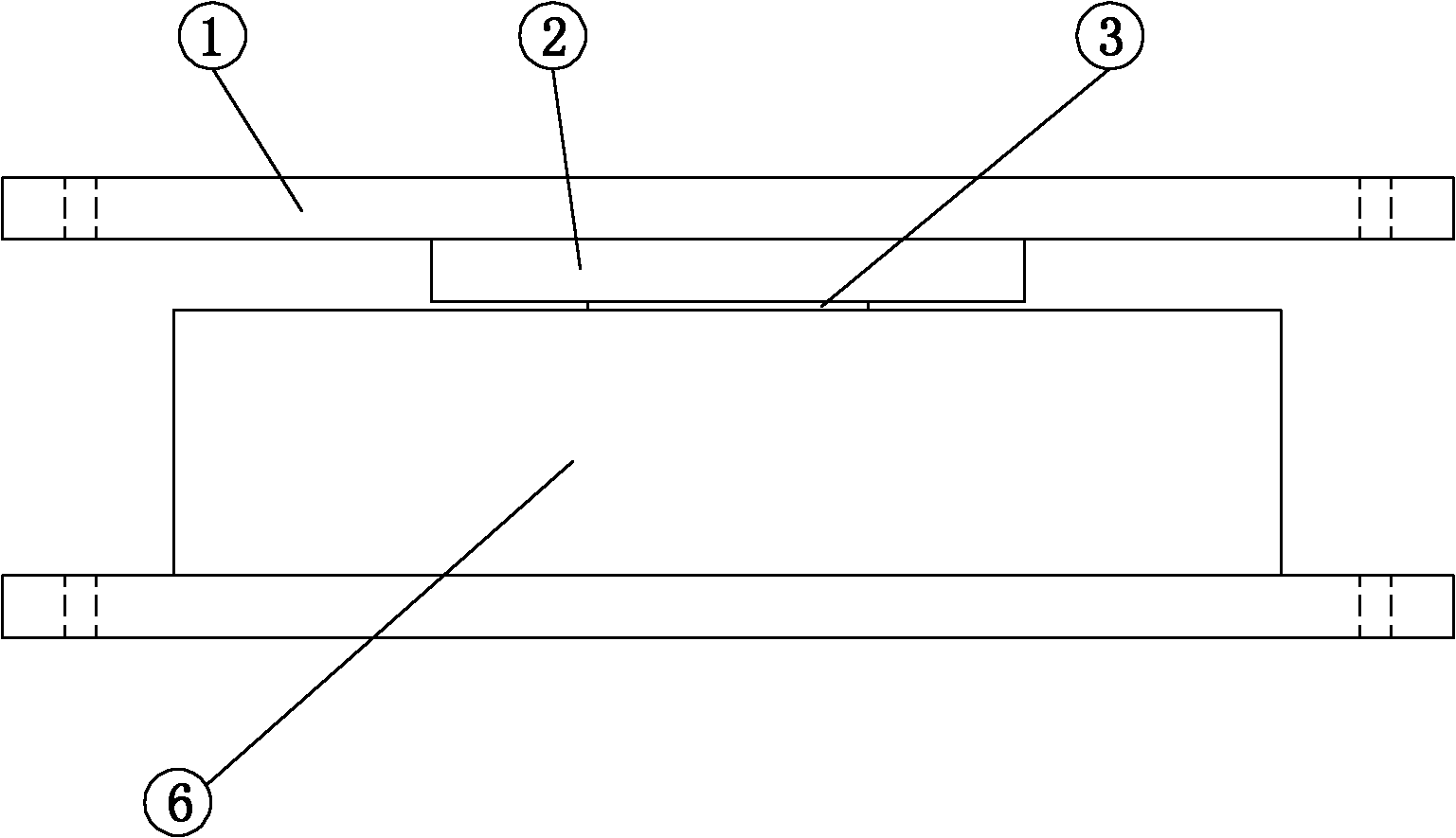

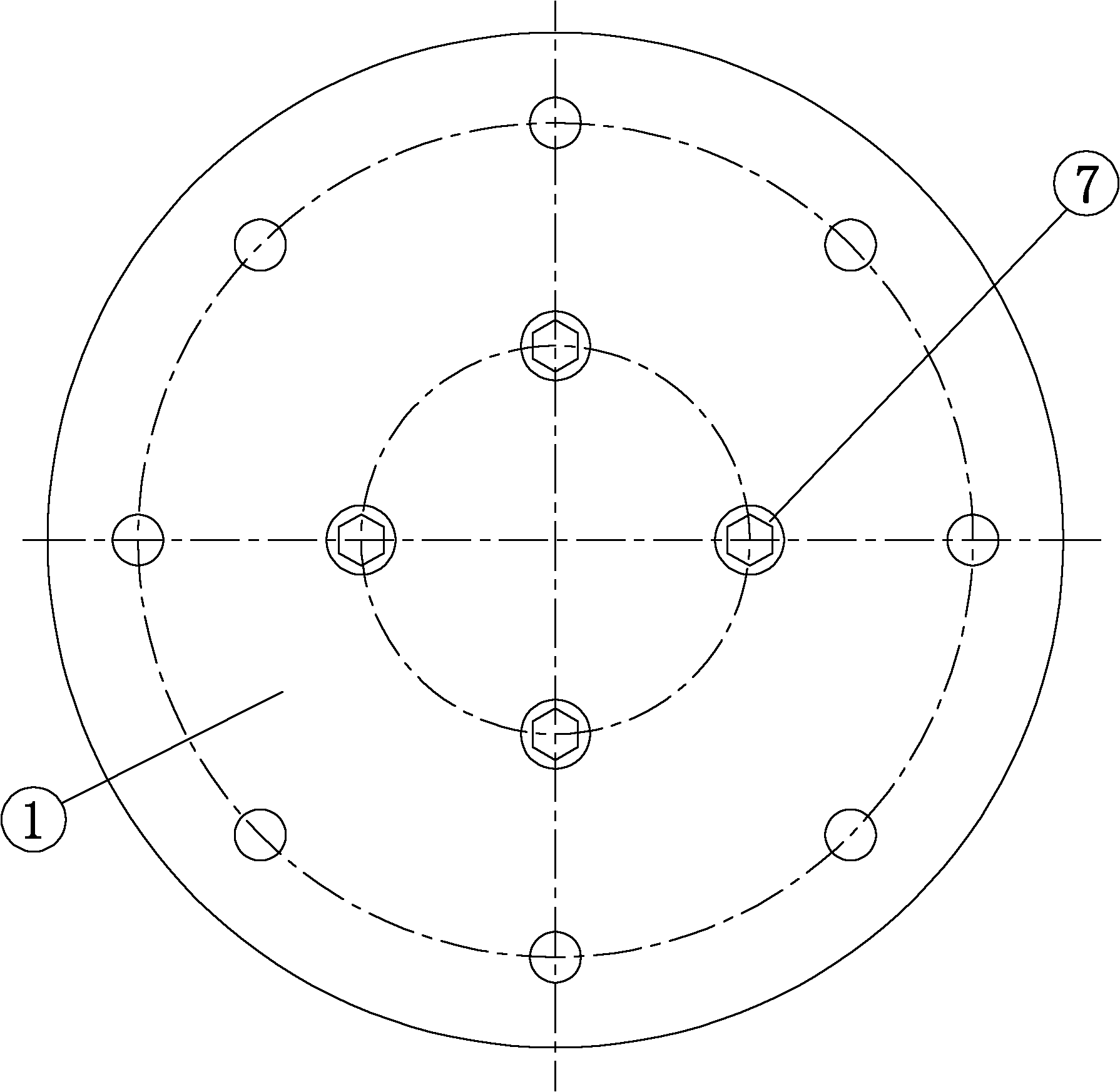

[0024] The anti-pull universal rolling bearing of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figures 1 to 3 An anti-pull universal rolling bearing is shown, the upper part of the bearing is a cover plate structure, and the cover plate structure includes three parts: the upper connecting plate 1, the upper seat plate 2 and the rolling plate 3. The upper connecting plate 1 is connected with the upper seat plate 2, the upper seat plate 2 is connected with the column of the rolling plate 3, and the three parts are connected to form an integral cover plate structure. The rolling plate 3 is supported on the balls 4, and the balls 4 are placed in the seat groove 5 at the bottom, and the seat groove 5 provides a rolling space for the roller shaft 4, so that the balls 4 can roll freely therein. A through cavity is formed between the upper seat plate 2 and the rolling plate 3, the upper plate of the anti-pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com