Detection system of feeding precision of revolving body special-shaped curve mechanism and detection method thereof

A detection system and a technology of a rotary body, which are applied in the testing of machines/structural components, testing of mechanical components, measuring devices, etc., can solve the requirements of the feed rate and feed accuracy of the special-shaped curve mechanism of the detection rotary body, three Coordinate measuring machines are expensive and limit the flexibility of testing work, so as to facilitate the separation and combination, improve reliability and credibility, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

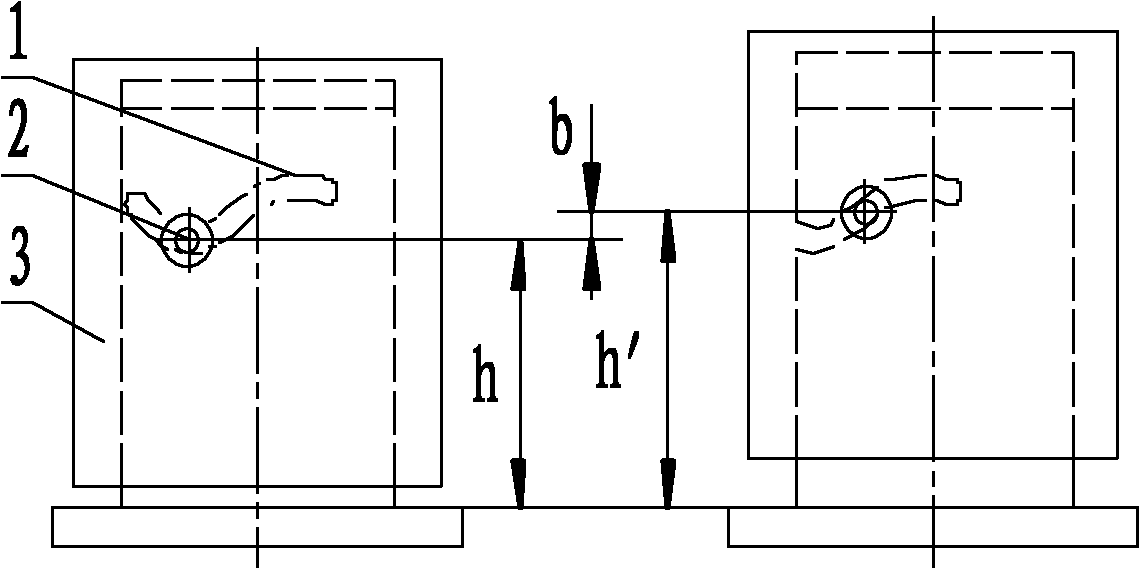

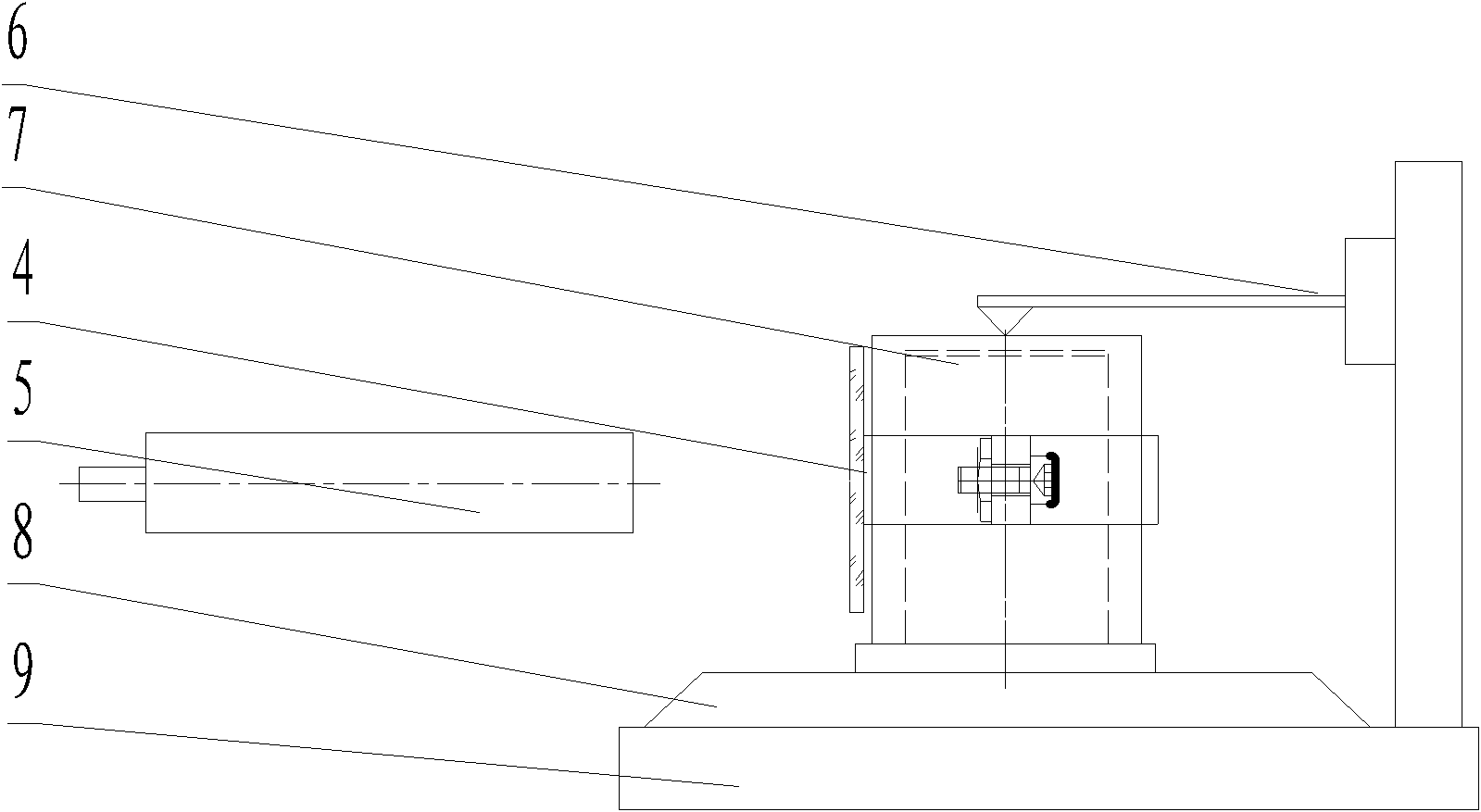

[0033] The detection equipment and tooling used in the present invention include: a digital display turntable, a digital display altimeter, an optical autocollimator, and a mirror tooling.

[0034] Among them, the digital display turntable is responsible for fixing the special-shaped curved groove of the rotary body and driving it to rotate; the digital display altimeter can directly measure the feed rate of the special-shaped curved mechanism of the rotary body; the mirror tooling is fixedly connected with the peripheral positioning parts to achieve reflection. The rotation angle of the mirror and the peripheral positioning parts is the same, and provides the aiming target for the optical autocollimator; High-precision targeting and positioning.

[0035] Optical autocollimation aiming positioning principle:

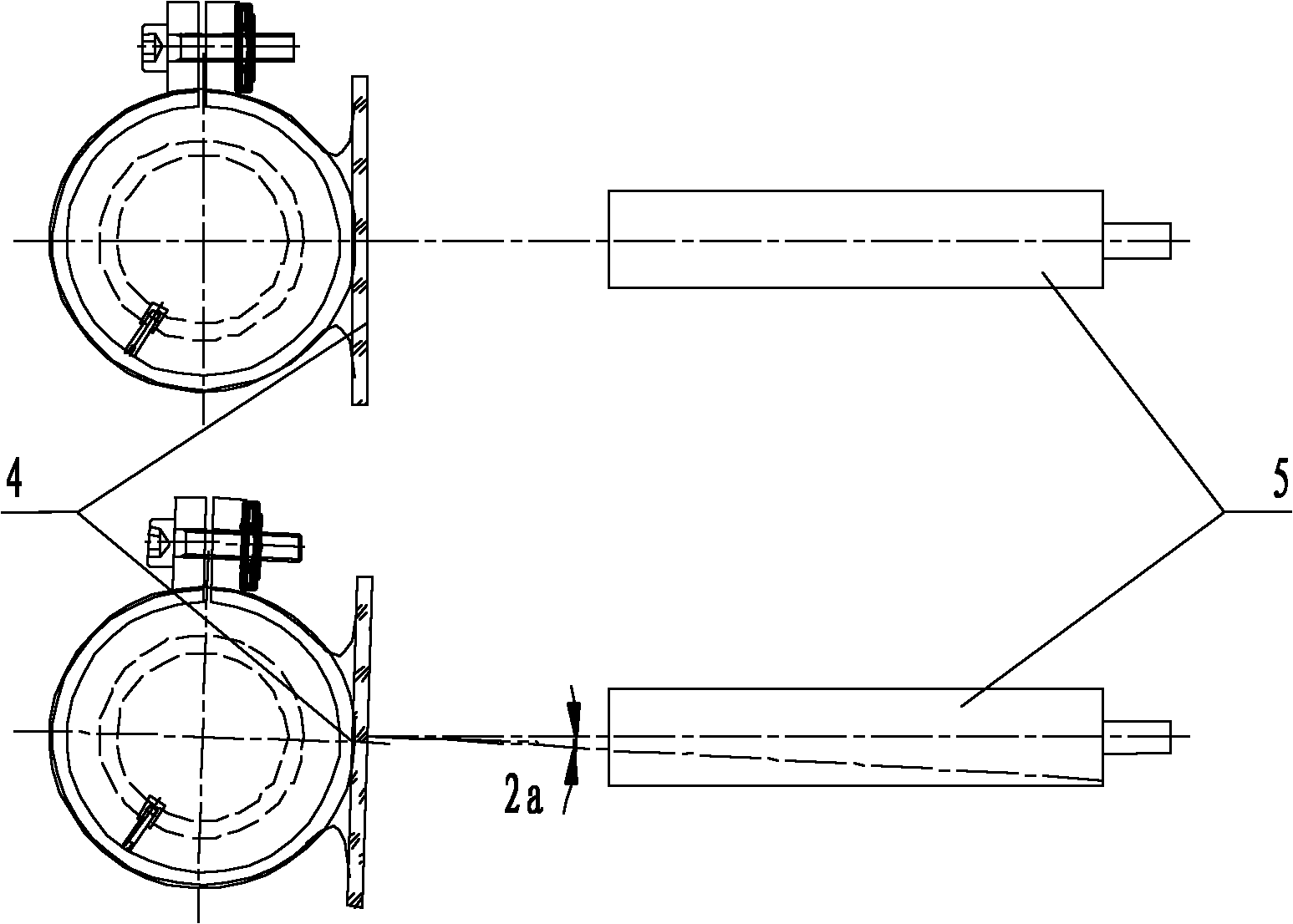

[0036] like figure 2 As shown in the figure above: when the normal of the tooling reflector 4 is parallel to the optical axis of the optical autocollimator 5, a light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com