Dynamic loading device for high-speed motorized spindle

A high-speed electro-spindle, dynamic loading technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve problems such as the inability to simulate the influence of electro-spindle, and achieve increased applicability and flexibility, authentic and reliable experimental data, and high loading accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

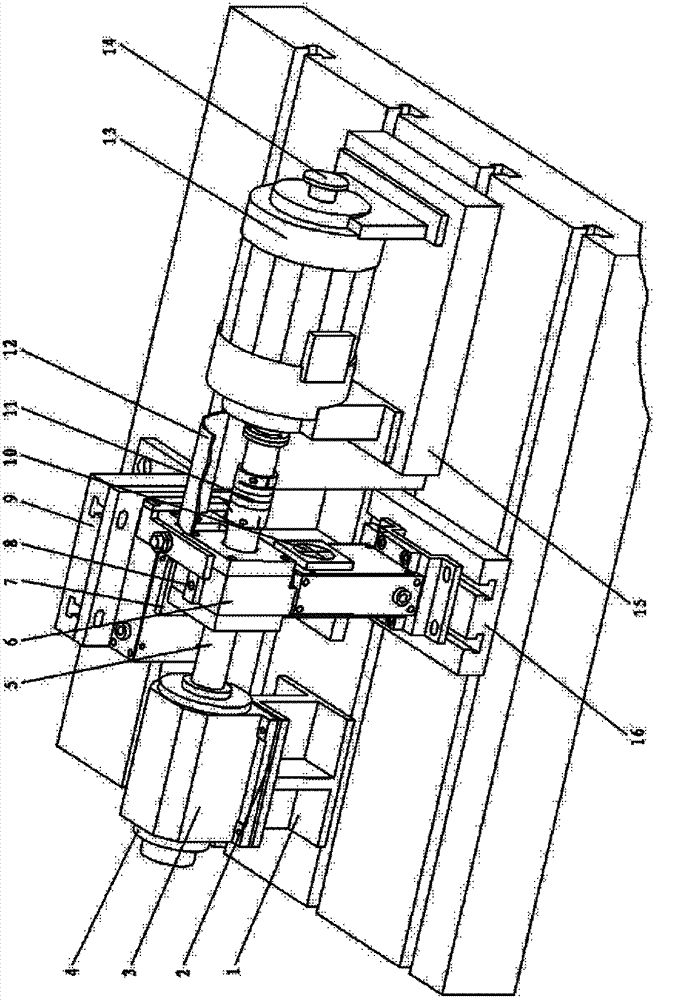

[0022] refer to figure 1 , The high-speed electric spindle dynamic loading device described in the present invention includes a supporting part, a loading part and an automatic control system.

[0023] 1. Support part

[0024] The supporting part includes a main shaft base, a radial loading backing plate 16 , an axial loading bracket 9 and a dynamometer base 15 .

[0025] The spindle base includes a spindle backing plate 1 , an adjusting gasket 2 and a clamping mechanism 3 . The spindle backing plate 1 is fixed on the horizontal iron with bolts, so that the measured high-speed electric spindle 4 can be axially adjusted along the longitudinal trapezoidal groove of the horizontal iron. By adjusting the structural size of the main shaft backing plate 1, the measured high-speed electric spindle 4 Make height adjustments. The radial loading backing plate 16 is a cuboid-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com