Built-in infrared touch screen

An infrared touch screen, built-in technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of circuit board warping, easy warping, circuit board deformation, etc., to achieve Ensure flatness, reduce thickness and enhance strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

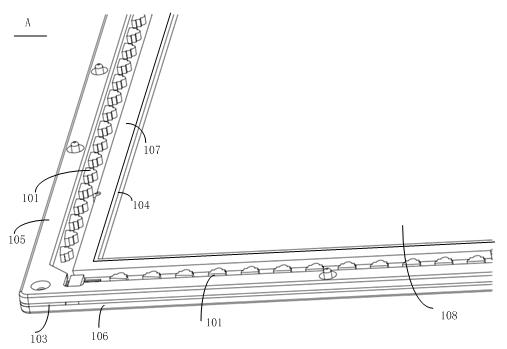

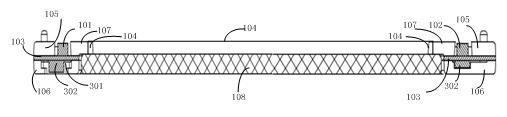

[0028] In this specification, for the convenience of description, in the state after the infrared touch screen is assembled, the state is observed from the front, and the side on which the infrared emitting tube or the infrared receiving tube is installed on the printed circuit board is called the upper surface of the printed circuit board, and the other side is called the upper surface of the printed circuit board. One side is called the lower surface of the printed circuit board, the support above the printed circuit board is called the upper support, and the support below the printed circuit board is called the lower support.

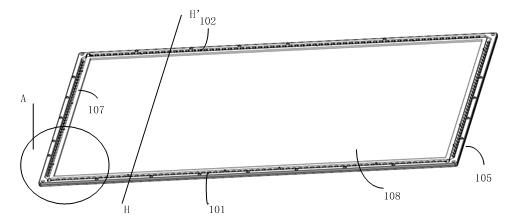

[0029] Attached below Figure 1 to Figure 7 The specific structure of the built-in infrared touch screen in the first embodiment of the present invention will be described in detail.

[0030] exist figure 1 , Figures 2 to 3 The built-in infrared touch screen of the first embodiment of the present invention shown in the figure includes an infrared ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap