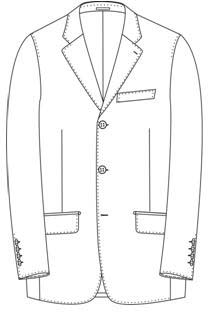

Method for manufacturing elastic suit for men

A processing method and elastic technology, applied in clothing, apparel, protective clothing, etc., can solve the problems of unsatisfactory appearance and other problems, and achieve the effect of humanized design, straight shape, and well-fitting clothing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the above step 1) the fabric is weft blended with 0.5% spandex fiber and radially blended with 2% spandex fiber; step 2) the bust size of the sample is 2cm smaller than the normal size, the waist size is 1.5cm smaller than the normal size, and the sleeve fat size is smaller than the normal size The size is 1cm smaller; Step 3) The chest lining is soaked in 35°C constant temperature water for 6 hours; Step 4) The fabric is naturally placed for 12 hours before cutting, and the cut pieces are placed in a constant temperature and humidity room for 2 hours (temperature 23°C, humidity 75 %).

Embodiment 2

[0022] In the above step 1) the fabric is weft blended with 1.5% spandex fiber and radially blended with 4% spandex fiber; step 2) the bust size of the model is 3cm smaller than the normal size, the waist size is 2.5 cm smaller than the normal size, and the sleeve fat size is smaller than the normal size The size is 2cm smaller; Step 3) The chest lining is soaked in 45°C constant temperature water for 7 hours; Step 4) The fabric is naturally placed for 18 hours before cutting, and the cut pieces are placed in a constant temperature and humidity room for 3 hours (temperature 28°C, humidity 85 %).

[0023] Process standard:

[0024] The cut piece is consistent with the model without error; the sewing stitches are smooth and standard; the ironing and undrawing standards are not stretched, and the natural state is maintained; the production is strictly in accordance with the process requirements, and the shape is flat and crisp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com