Method of preparing supporting type ionic liquid membrane by using high-pressure carbon dioxide under low temperature

A high-pressure carbon dioxide and ionic liquid technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as unstable performance, difficult membrane production, low efficiency, etc., achieve good liquid filling quality and improve mechanical stability , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

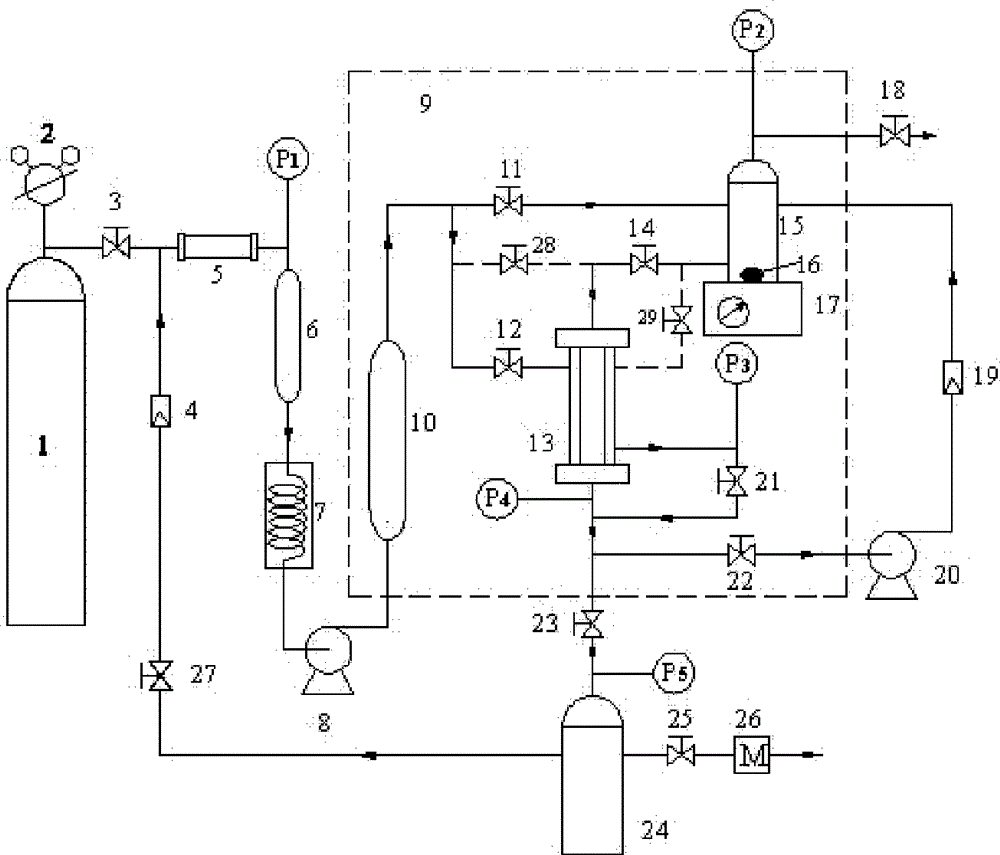

Embodiment 1

[0016] A ceramic tube with a pore size of 20nm, an inner diameter of 7mm, an outer diameter of 10mm, and a length of 250mm is inserted into the membrane module 13. Ionic liquid [omim][PF 6 ] And the agitator into the storage tank 15, after sealing, connected to the film making device. Then the system is evacuated, the rest of the valves are opened except the pressure reducing valve 2 and the regulating valve 14, and the pressure reducing valve 2 is adjusted to slowly send carbon dioxide into the system and replace the air in it. After about 10 minutes, all valves are closed. After the emptying is completed, open valves 2, 3, 11, 12, and inject carbon dioxide into the storage tank 15 and the membrane module 13. At this time, turn on the magnetic stirrer so that the carbon dioxide can be fully dissolved in the ionic liquid. The pressure is adjusted by the high-pressure plunger pump 8 to control the system pressure at 10 MPa, and the valves 2, 3, 11, and 12 are closed when the set ...

Embodiment 2

[0018] A ceramic tube with a pore diameter of 20nm, an inner diameter of 7mm, an outer diameter of 10mm, and a length of 250mm is inserted into the membrane module 13. Ionic liquid [bmpy][BF 4 ] And the stirrer are loaded into the storage tank 15, after being sealed, connected to the film making device. Then the system is evacuated, the rest of the valves are opened except the pressure reducing valve 2 and the regulating valve 14, and the pressure reducing valve 2 is adjusted to slowly send carbon dioxide into the system and replace the air in it. After about 10 minutes, all valves are closed. After the emptying is completed, open valves 2, 3, 11, and 12, and inject carbon dioxide into the storage tank 15 and the membrane module 13. At this time, the magnetic stirrer is turned on so that the carbon dioxide can be fully dissolved in the ionic liquid. When the system pressure reaches the set value of 11MPa, the pump 8 and valves 2, 3, 11, 12 are closed, and the oven temperature is...

Embodiment 3

[0020] A ceramic tube with a pore diameter of 10 nm, an inner diameter of 7 mm, an outer diameter of 10 mm, and a length of 250 mm is loaded into the membrane module 13, the ionic liquid [hmim] [Tf2N] and the stirrer are loaded into the storage tank 15, sealed, and connected to the membrane making device. The system is evacuated. Open the rest of the valves except the pressure reducing valve 2 and the regulating valve 14, and then adjust the pressure reducing valve 2 to slowly send carbon dioxide into the system and replace the air in it. After about 12 minutes, close all valves. After the emptying is completed, open valves 2, 3, 11, and 12, and inject carbon dioxide into the storage tank 15 and the membrane module 13. At this time, the magnetic stirrer is turned on so that the carbon dioxide can be fully dissolved in the ionic liquid. After the high pressure plunger pump 8 adjusts the pressure to a set value of 9 MPa, the valves 2, 3, 11, and 12 are closed. The temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com