Production method of phase-change memory

A technology of phase change memory and manufacturing method, which is applied in the field of phase change memory, and can solve problems such as difficulty in achieving uniform coverage of metal seed layers, poor filling ability of small holes, poor electroplating results, etc., and achieve good filling quality of small holes , low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

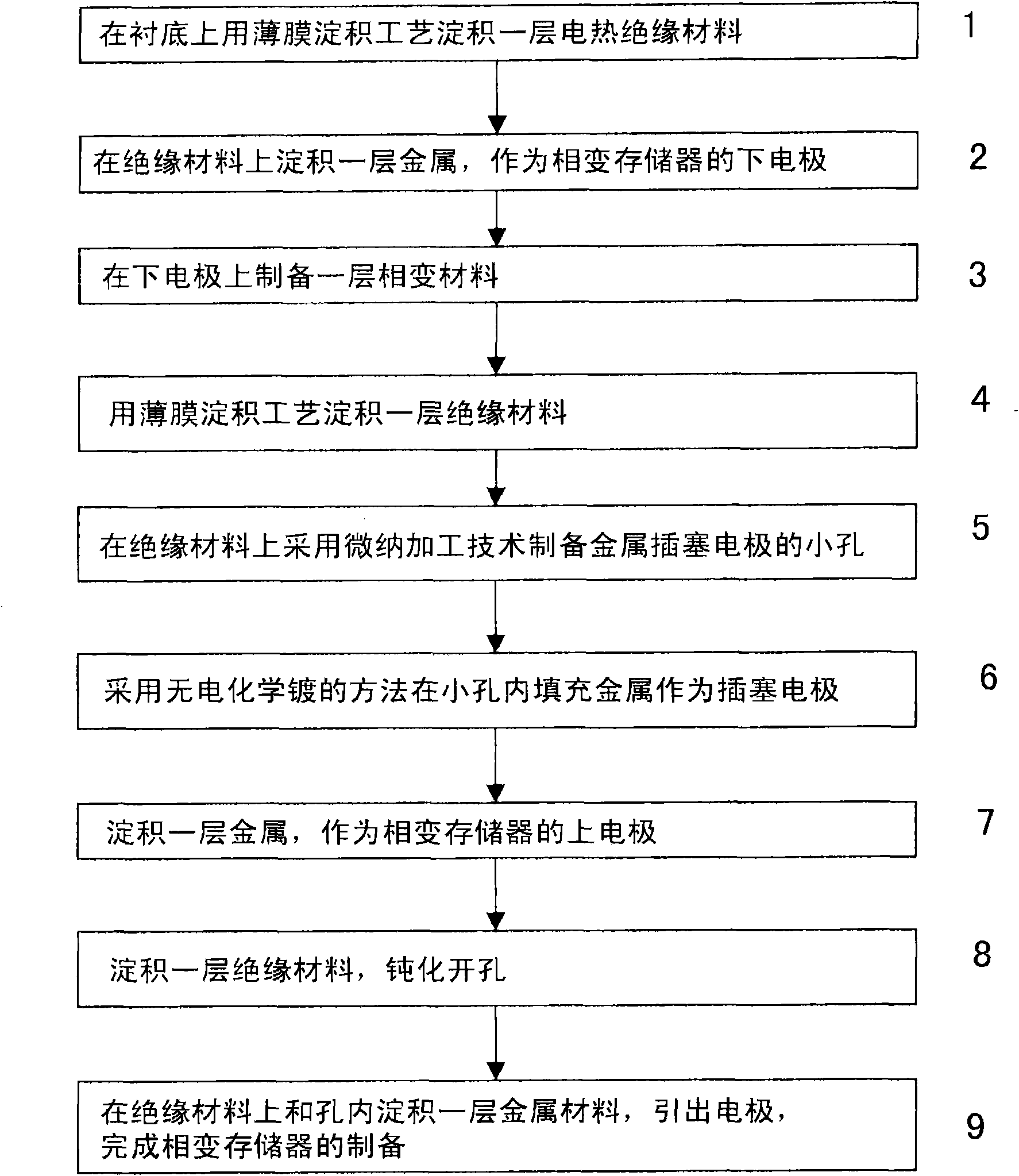

[0029] see Figure 1 to Figure 10 As shown, the present invention introduces a preparation method of a phase change memory, comprising the following steps:

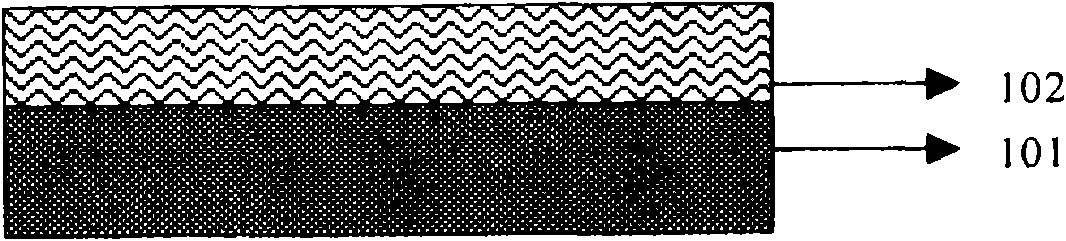

[0030] Step 1: Deposit a layer of first insulating material layer 102 on the substrate 101 . The substrate 101 is a semiconductor material substrate silicon wafer, or a substrate including a phase-change memory drive circuit; the first insulating material layer 102 can be oxide, nitride, sulfide or oxide Any one of a mixture of at least two of , nitride, and sulfide; the first insulating material layer 102 grown on the substrate can be sputtered, evaporated, or plasma-assisted deposition method, chemical vapor deposition method, metal-organic compound thermal decomposition method, laser-assisted deposition method and thermal oxidation method (such as figure 2 shown);

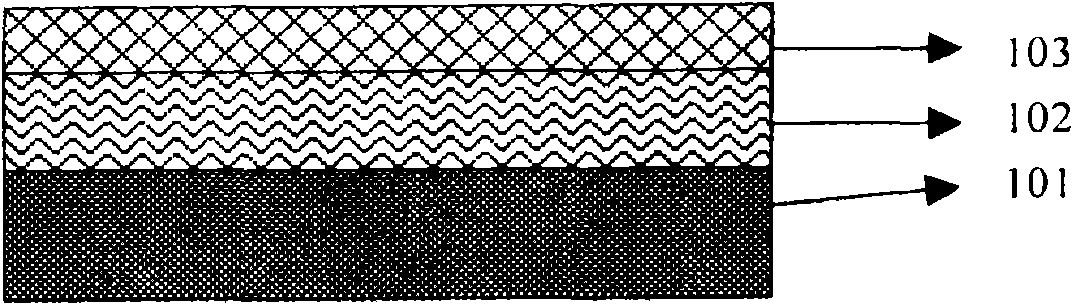

[0031] Step 2: Deposit a layer of metal layer 103 on the first insulating material layer 102 as the lower electrode of the phase change memory; the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com