Pulse energy storage type high-pressure water jet cleaning system

A high-pressure water jet and cleaning system technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of lack of pulsating outflow characteristics of plunger pumps and unimaginable cleaning effects. , to achieve the effect of adapting to large-scale cleaning operations, improving impact force and crushing capacity, and large output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A pulse-storage high-pressure water jet cleaning system, comprising: a power distribution device, a high-pressure water pump, an air pressure energy storage device, and a pulse injection device, the power distribution device is connected to the high-pressure water pump, and the pulse injection device is connected to the high-pressure water pump through the air pressure energy storage device .

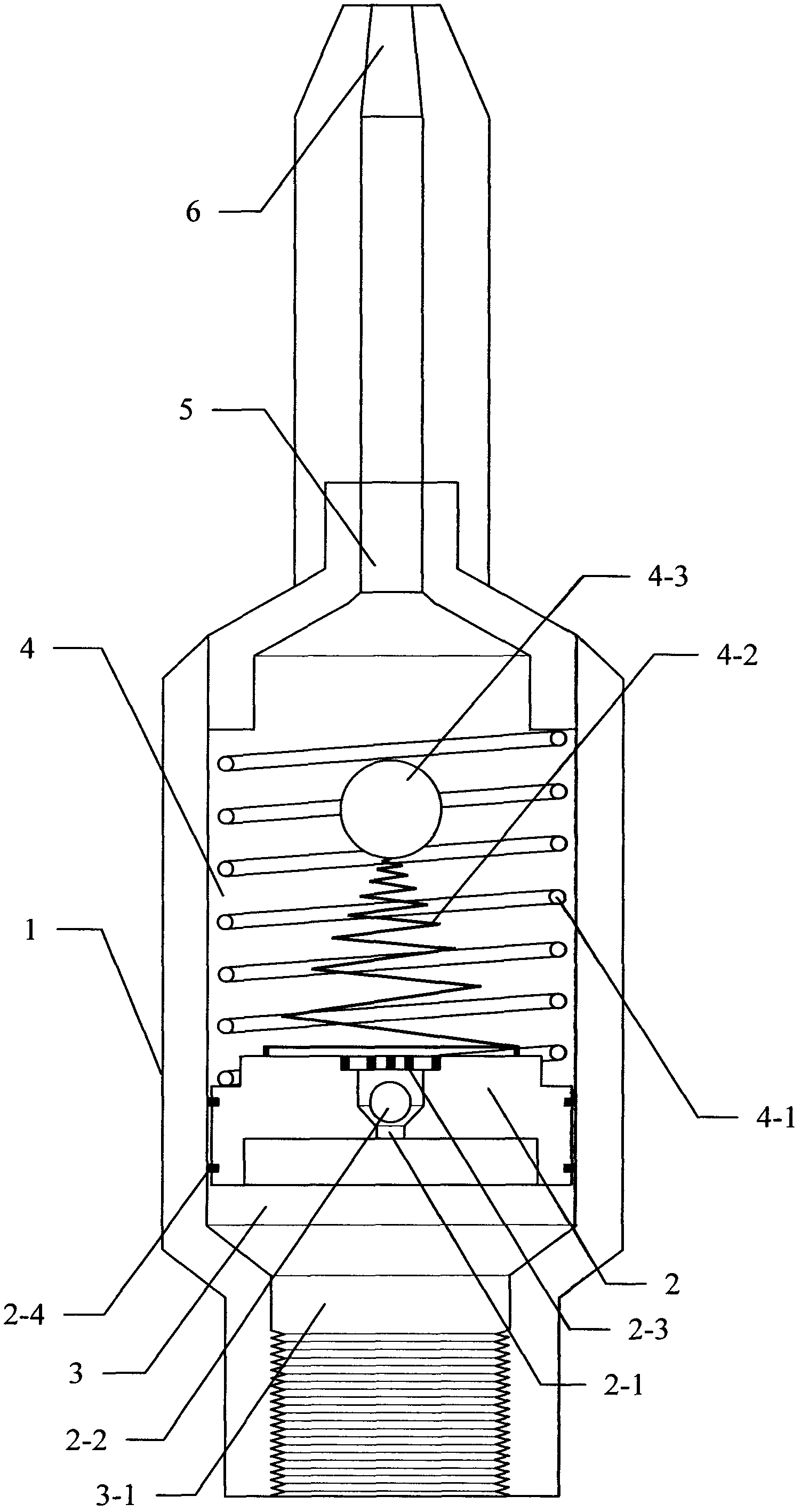

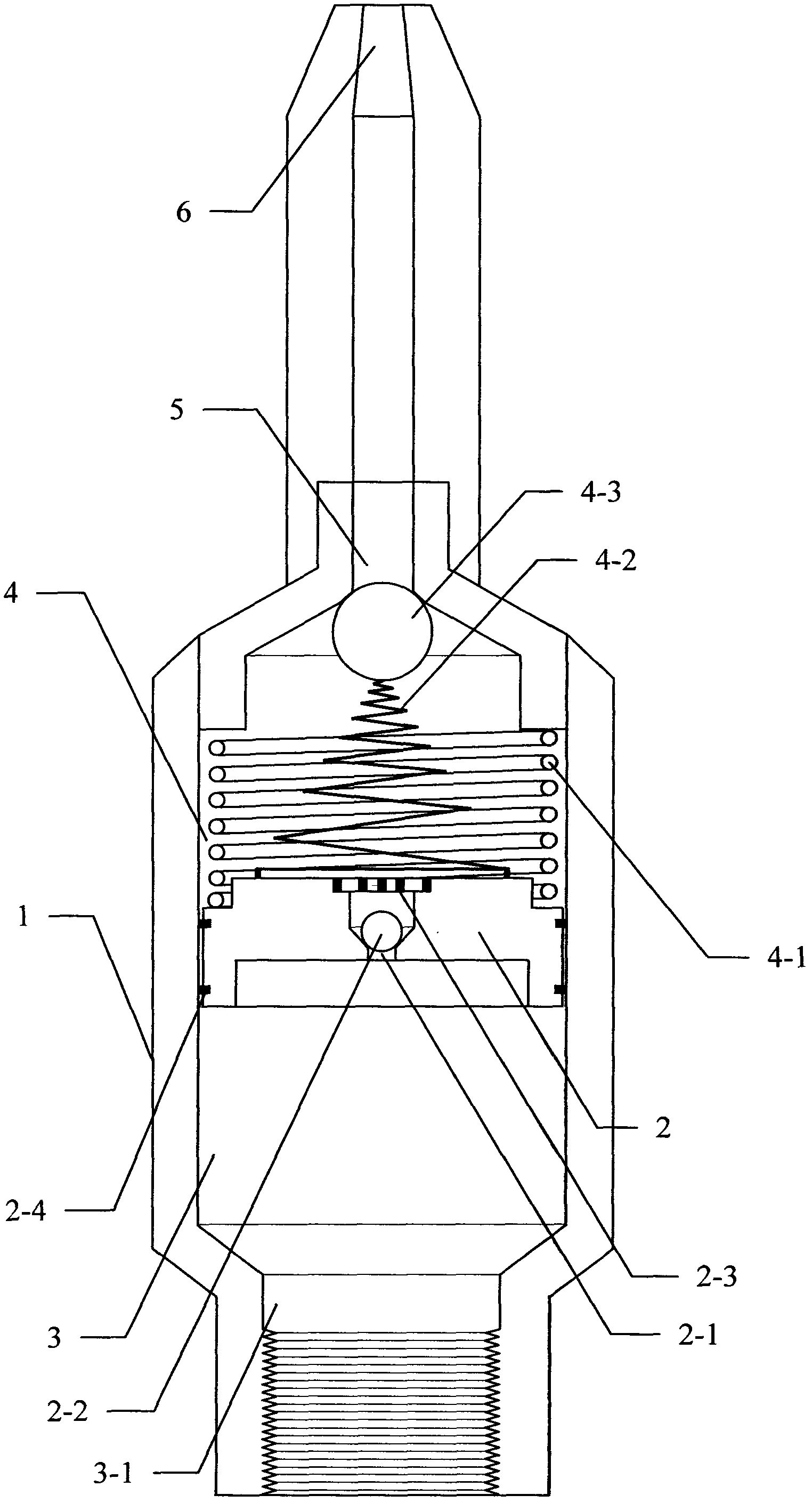

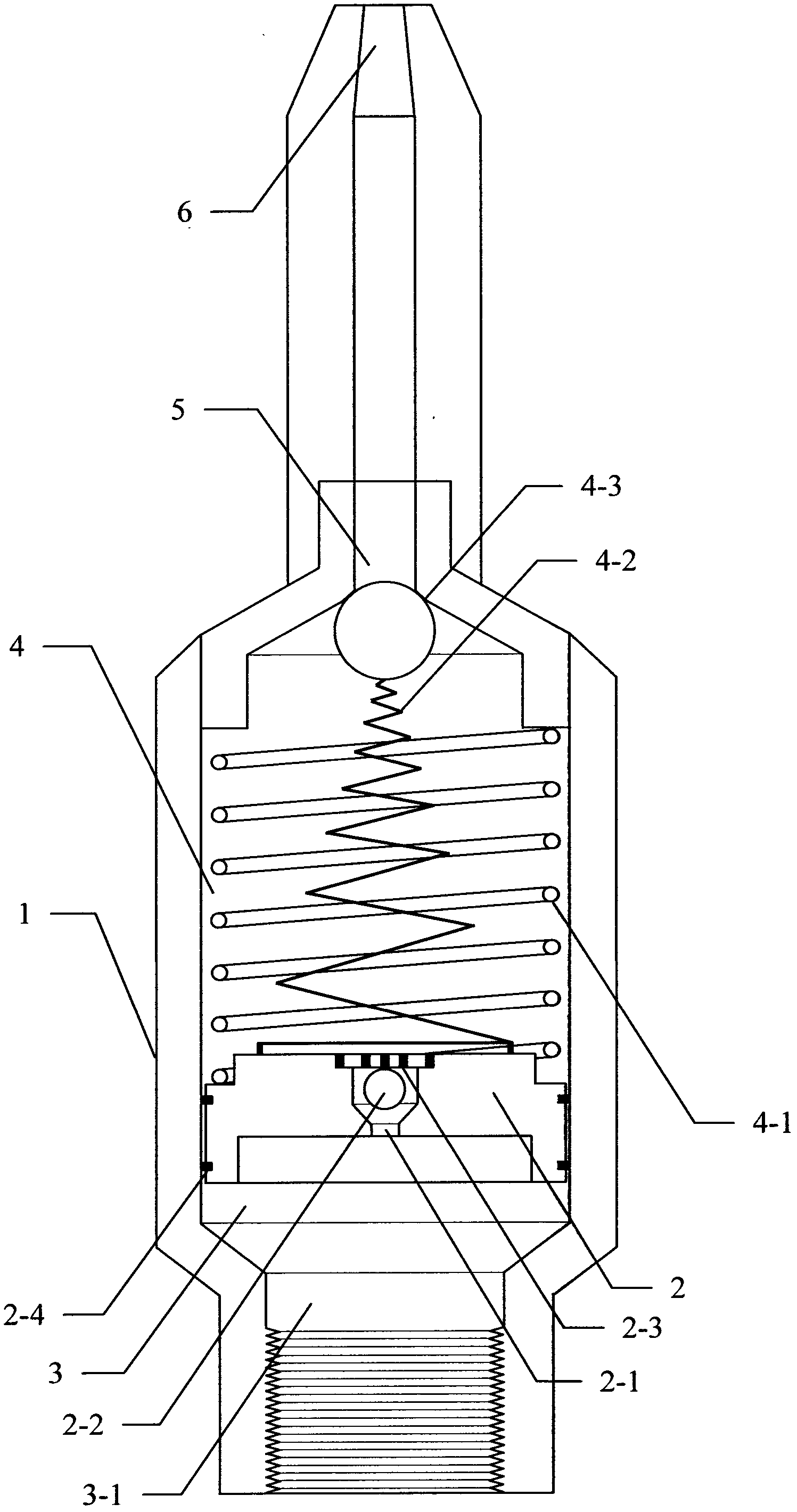

[0019] Pulse jet device, if attached figure 1 , 2, 3, including: a housing 1, a piston 2, the piston 2 divides the inner chamber of the housing 1 into a water inlet chamber 3 and a compression chamber 4, and the water inlet chamber 3 communicates with the water inlet channel 3-1 and the water delivery pipe The pneumatic energy storage device is connected, and the piston 2 is provided with a compression chamber 4 water supply check valve and an elastic water stop ring 2-4, and the elastic water stop ring 2-4 is fixed on the outside of the piston 2, and the compression chamber 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com