Continuous die for producing connecting pieces of air conditioner and method for continuously producing connecting pieces of air conditioner

A technology of connectors and air conditioners, applied in the field of continuous molds, can solve the problems of low efficiency, waste of equipment and labor, and achieve the effects of improving production efficiency, improving accuracy, and saving manpower and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

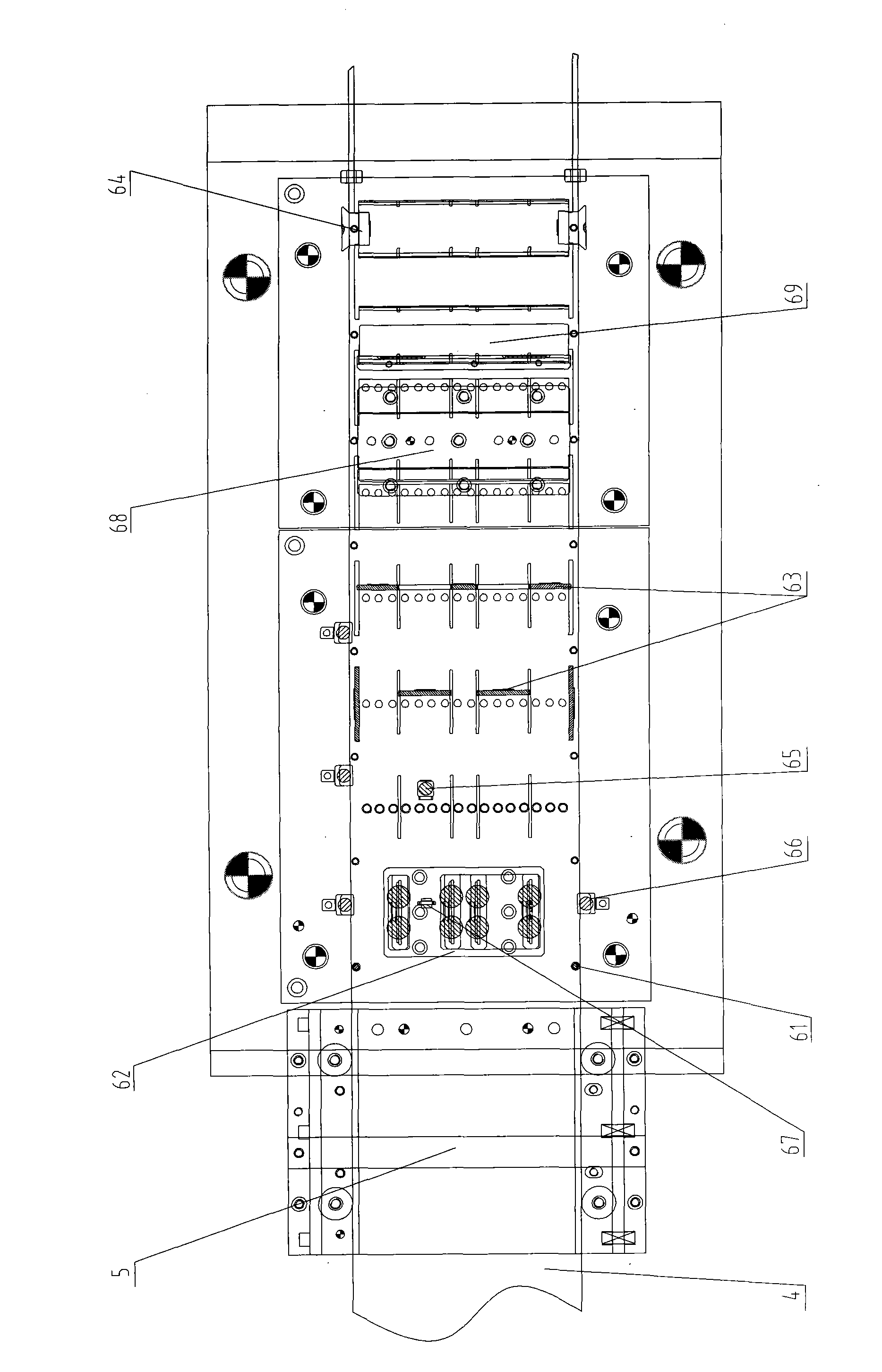

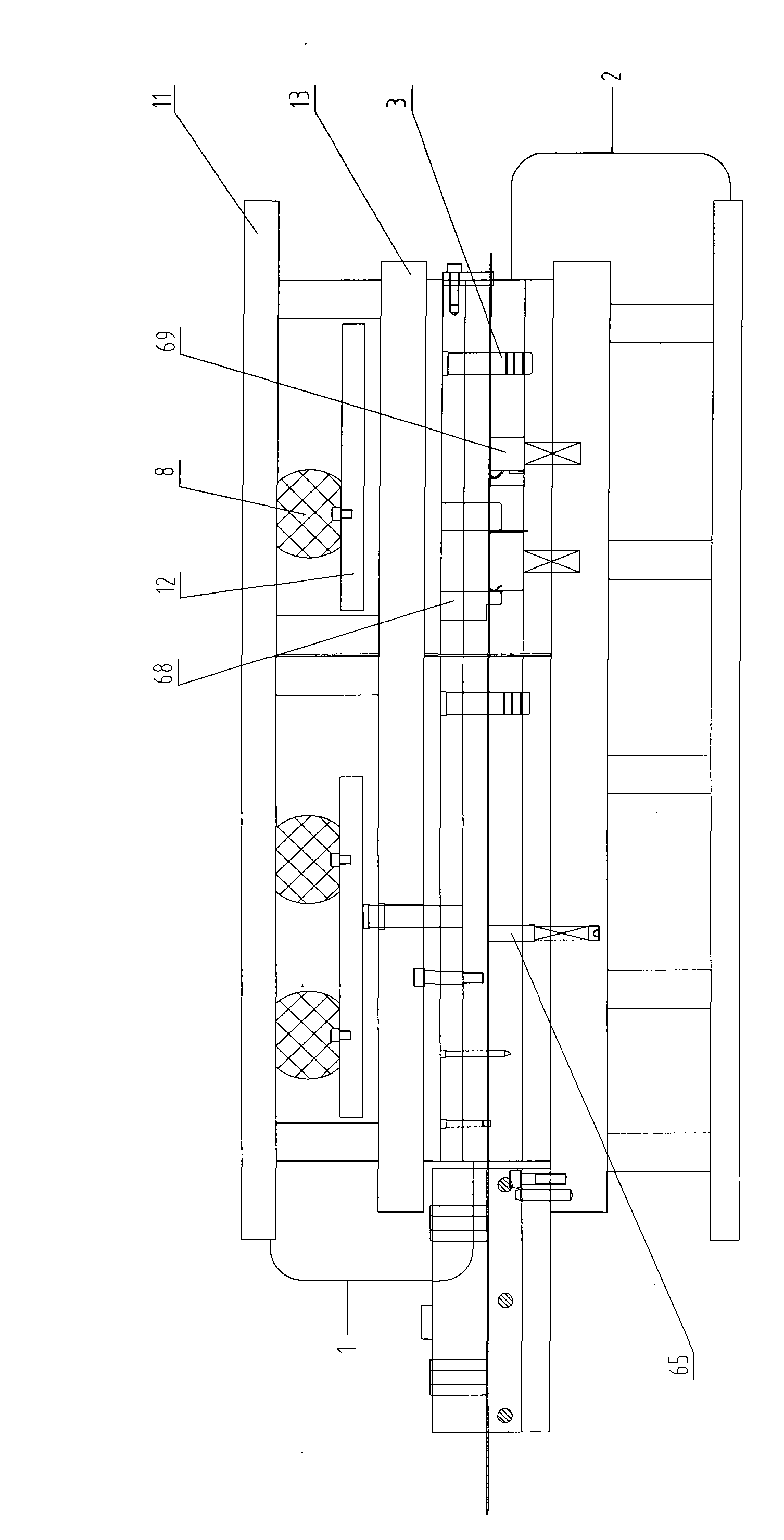

[0035] Example 1, such as figure 1 and figure 2 As shown, the present invention discloses a continuous mold for producing air-conditioning connectors, including an upper mold 1 and a lower mold 2, the upper mold 1 and the lower mold 2 are connected by an inner guide post 3, and a mold cavity is formed between the upper and lower molds , the strip material 4 is sent into the mold cavity by the feed rack 5, and the round hole punch 61, the elongated hole punch 62, the trimming punch 63, and the cutting punch 64 are set on the upper die 1; There is an initial positioning block 65 and a dual-purpose floating block 66 for determining the step distance; matching bridge forming punches 67, 90° bending forming punches 68 and 46° angle bending forming are set on the upper die 1 and the lower die 2 Punch 69. The upper die 1 includes an upper die base 11, an upper backing plate 12 and an upper template 13, and an elastic member 8 is arranged between the upper die base 11 and the upper...

Embodiment 2

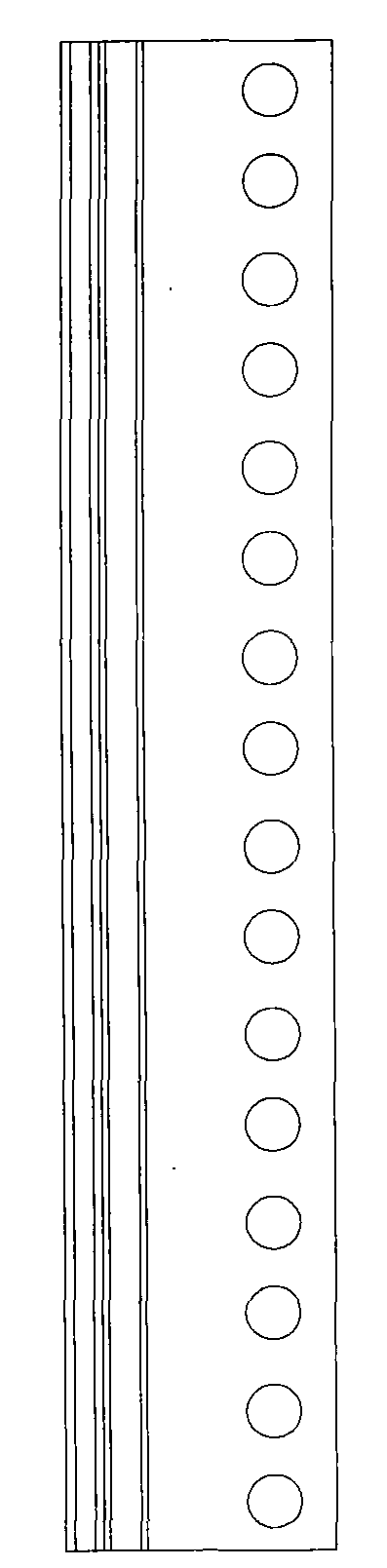

[0037] Embodiment 2, produce another kind of air-conditioning connector product by interchangeable structure, the difference between this product and the air-conditioning connector product in embodiment 1 is that there are no long holes, so this embodiment is different from the continuous mold of embodiment 1 The difference is that the punch 62 for punching elongated holes is removed, and correspondingly, the step of punching elongated holes on the strip is also omitted in the production method. Specific products such as image 3 , Figure 4 and Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com