Milling edge-aligning beveller and processing method thereof

A technology of chamfering machine and angle machine, which is applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing accuracy and automation, inconvenient processing of similar transmission shafts, etc., and achieve a feasible and automatic processing method High degree of effect with a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

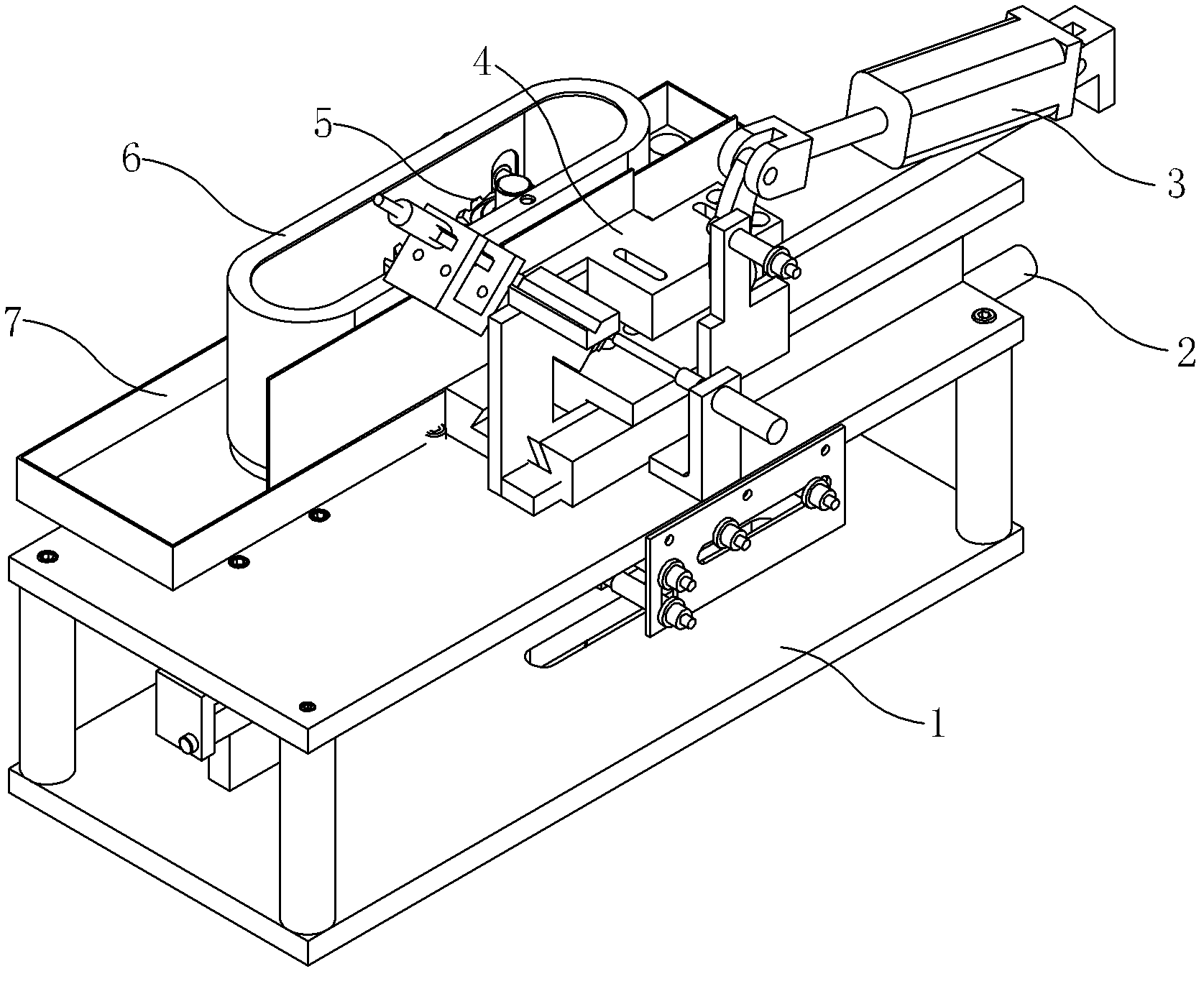

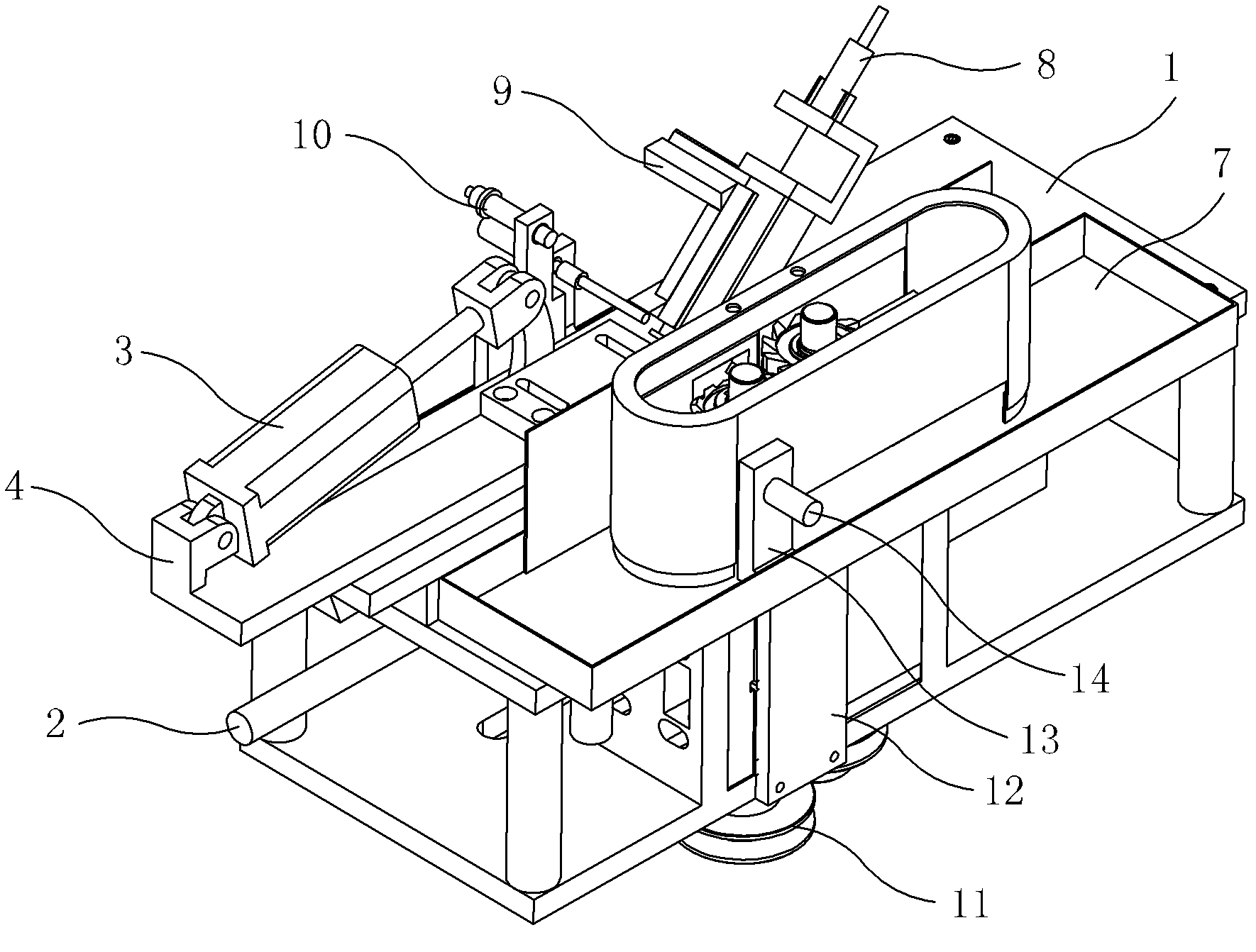

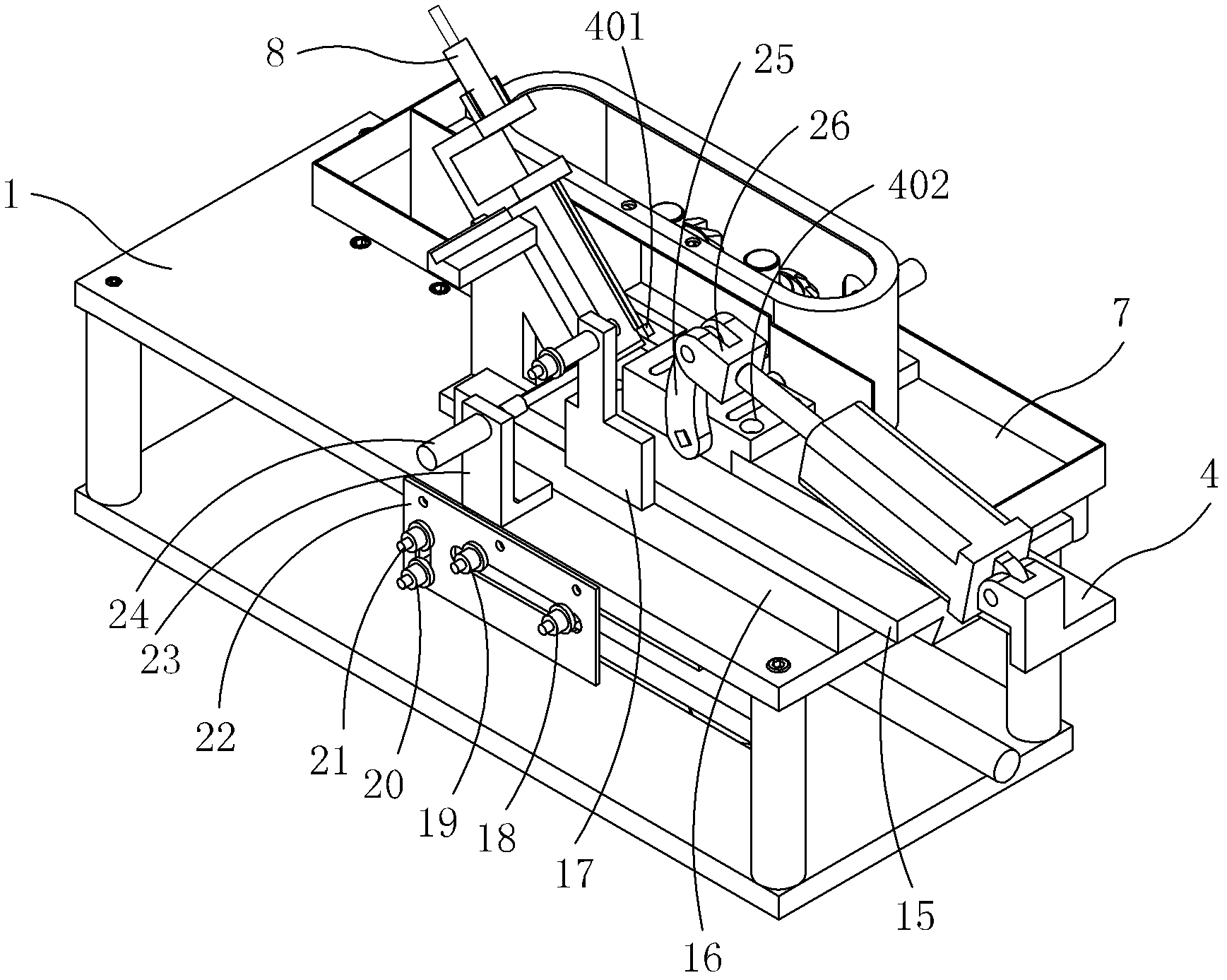

[0024] Now take the present invention of LT-XD01 model as an example in conjunction with the accompanying drawings, and further describe its structure and use. like Figure 1 to Figure 5As shown, the workbench 1 of the milling and chamfering machine is provided with a feeding mechanism, a clamping mechanism, a translation mechanism, a transmission mechanism, a discharging mechanism, and a waterproof mechanism. The clamping mechanism and the discharging mechanism are respectively arranged on the transmission mechanism The clamping mechanism is connected with the feeding mechanism, the clamping mechanism is connected with the translation mechanism, the transmission mechanism is provided with a waterproof mechanism, and the induction switch bracket 17 on the side of the workbench is provided with a right induction switch 18, a left induction switch 19, and a lower induction switch. Switch 20, upper induction switch 21. Described feeding mechanism is made up of first feeding cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com