Bag making machine capable of continuously sealing bags

A bag making machine and bag technology, which is used in container manufacturing machinery, box making operations, rigid/semi-rigid container manufacturing, etc., can solve the problem of being quite firm that cannot be sealed, and achieve lightweight, precise adjustment, and difficult to seal. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

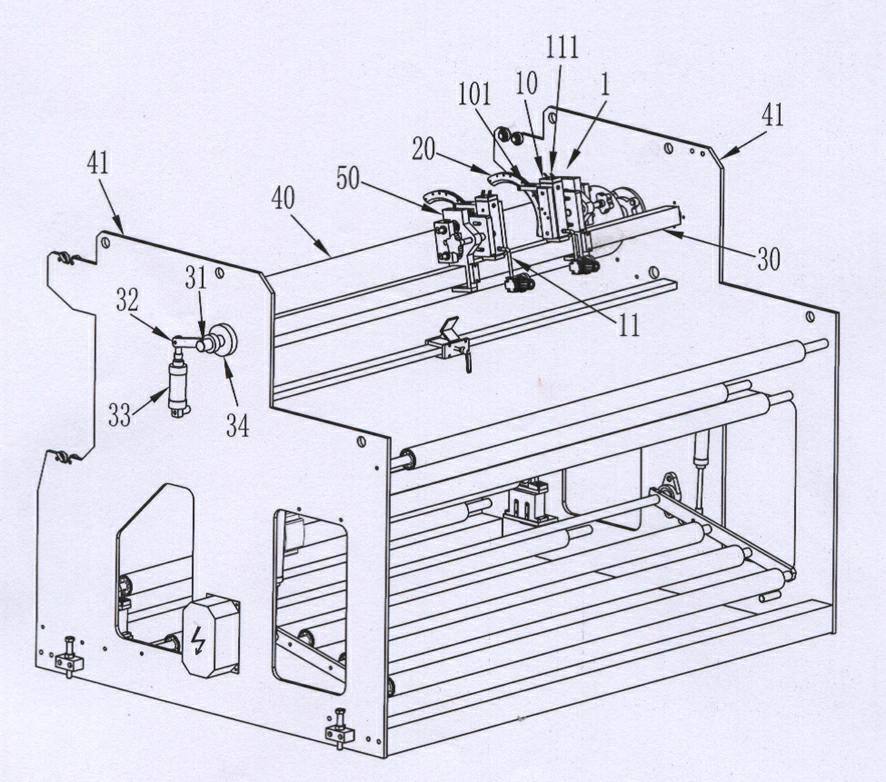

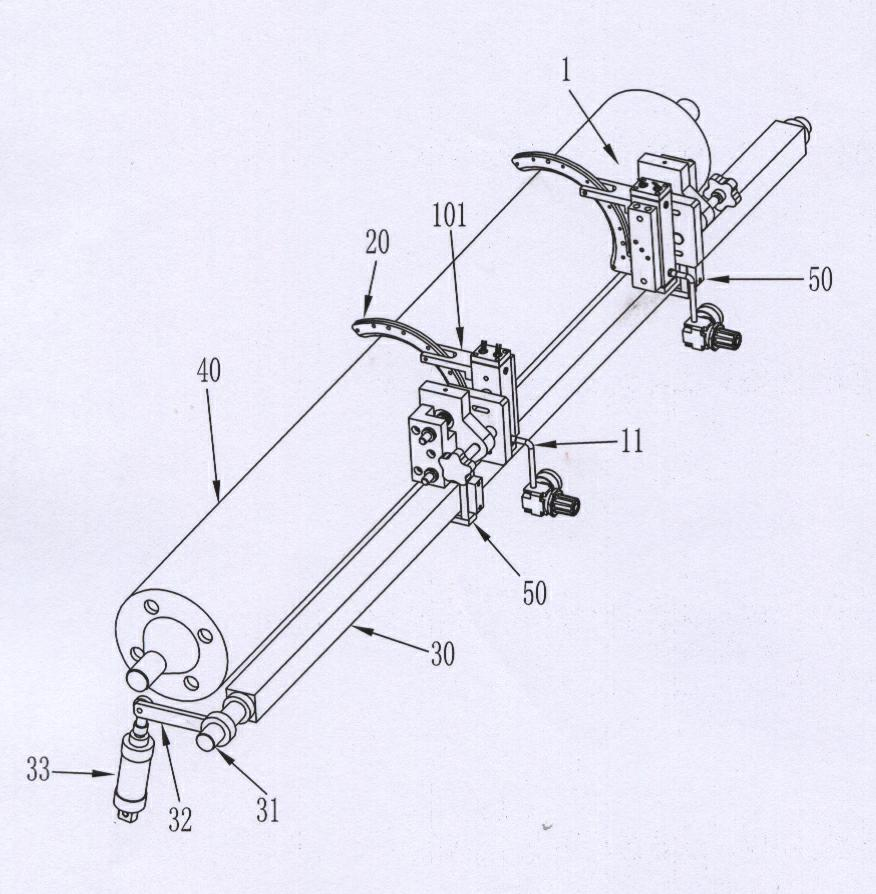

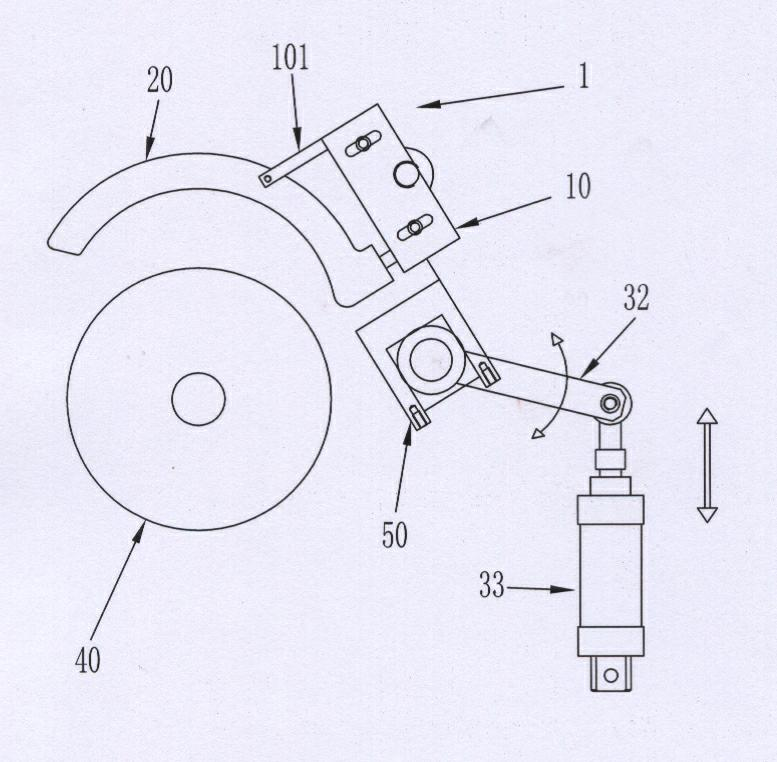

[0027] The accompanying drawings show the structure of the present invention and its embodiments, and further describe the relevant details of the embodiments in conjunction with the accompanying drawings. like figure 1 , 2 As shown, wall panels 41 are respectively provided on both sides of the bag making machine, and roller shafts 40 are arranged between the wall panels 41, and a rotating shaft 30 is provided on the wall panels 41, and a spacing adjustment mechanism 50 is provided on the rotating shaft 30. The hot gas sealing knife assembly is arranged on the distance adjustment mechanism, and the distance adjustment mechanism includes a movable bracket with holes, the movable bracket is movably sleeved on the rotating shaft, and fastening bolts are arranged on the bracket. The distance adjustment mechanism 50 can move toward or relative to each other along the rod body of the rotating shaft 30. In addition, the distance adjustment mechanism 50 is provided with a sealing kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com