Booster with emergency braking function

A technology of emergency braking and booster, applied in the directions of brakes, brake transmissions, transportation and packaging, etc., can solve the problems of rapid pressing and potential safety hazards, and achieve improved braking force, low cost, and simple component structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

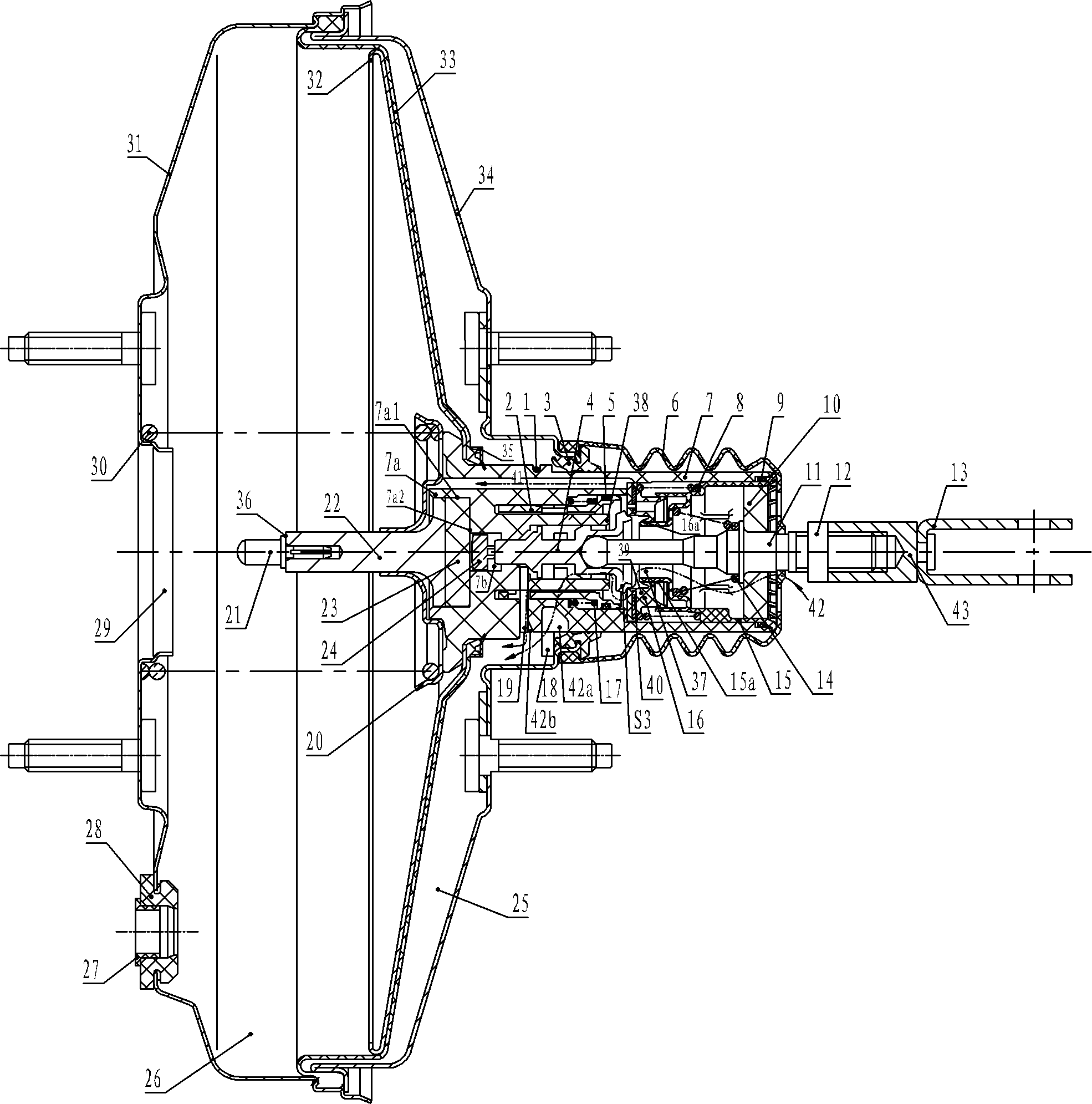

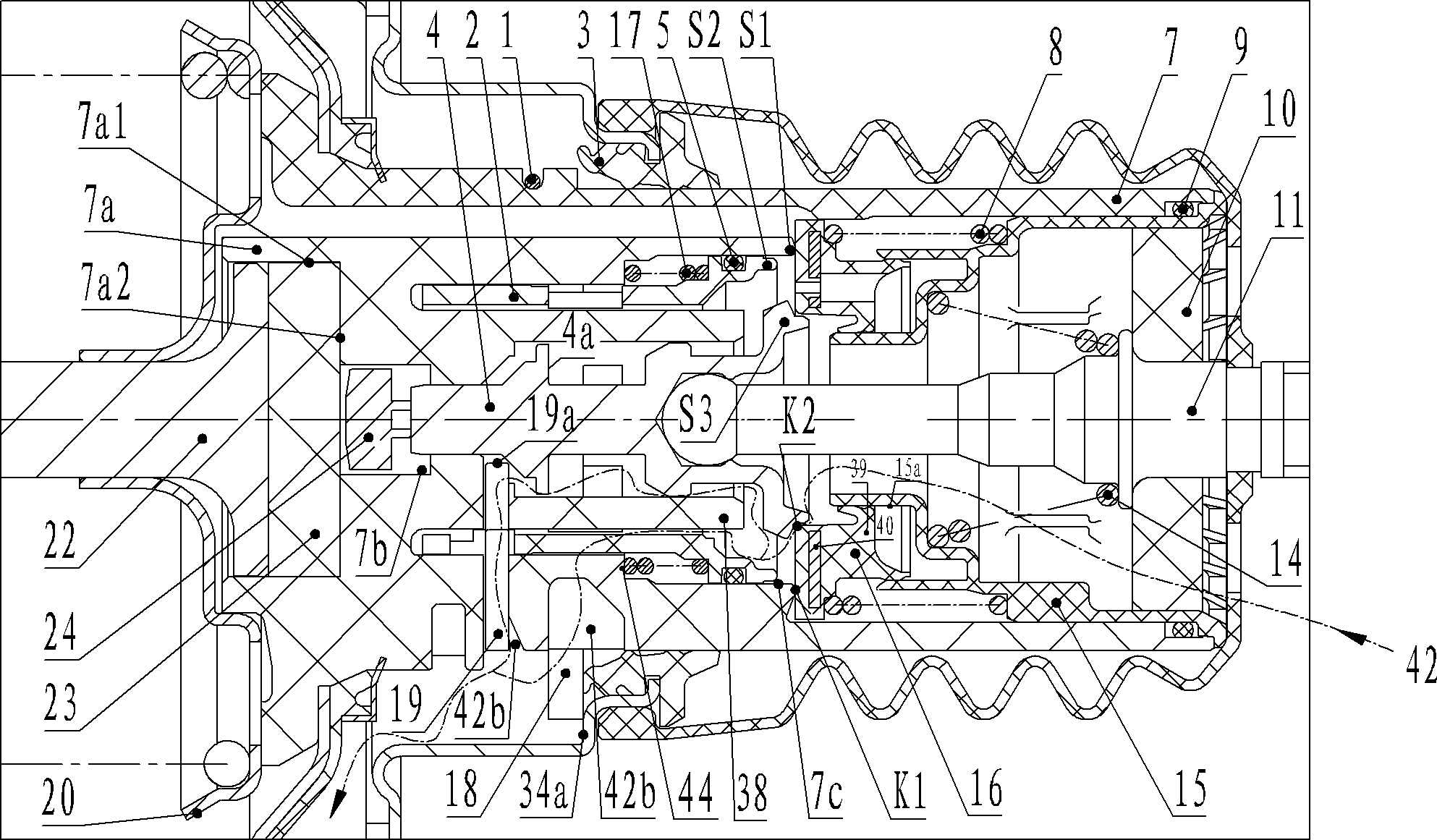

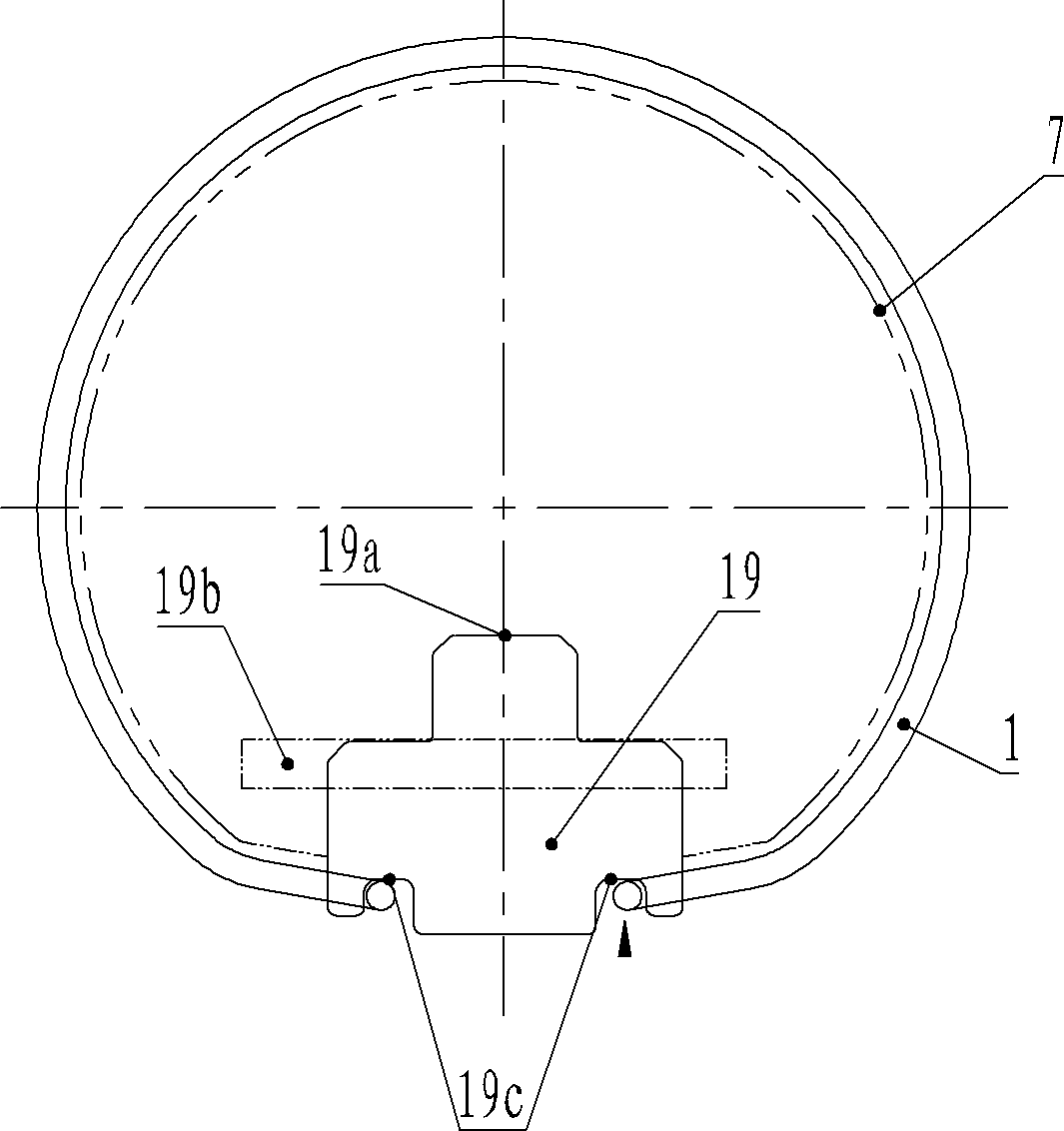

[0031] Such as figure 1 , figure 2 As shown, a booster with an emergency braking function includes a rear shell 34 and a front shell 31, and a piston housing 7 is slidably installed in the rear shell. An annular rear housing sealing ring 3 is installed at the rear housing mouth, so that the piston casing periphery and the rear housing 34 form a seal. It also includes a diaphragm 33 whose outer edge is tightly sealed to the housing, a diaphragm 32 that cooperates with the diaphragm 33, the diaphragm 32 and the diaphragm 33 are connected to the outer periphery of the piston housing 7, and the diaphragm, diaphragm 33 are connected by the locking plate 35 The diaphragm is riveted and fixed on the piston casing, and the piston casing, diaphragm 32 and diaphragm 33 divide the interior of the booster into front and rear chambers, the front chamber is a vacuum chamber 26, and the rear chamber is an atmospheric chamber 25; the front housing 31 is riveted and sealed with the rear she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com