Hydraulic cylinder assembly for linkage braking system and motorcycle comprising hydraulic cylinder assembly

A braking system and hydraulic cylinder technology, applied in the direction of brake actuators, gear shifting mechanisms, mechanical equipment, etc., can solve the problems of insufficient response, small braking deceleration, long braking distance, etc., to increase safety and stability, increase braking deceleration, reduce the effect of sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

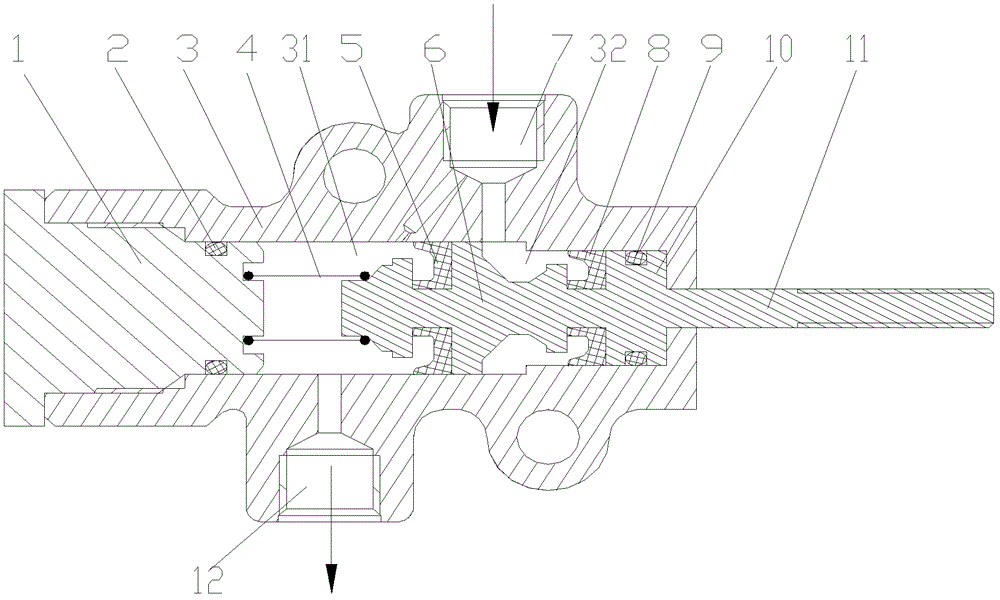

[0019] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the hydraulic cylinder assembly for the linkage braking system of this embodiment includes a cylinder block 3 and a piston 6 located in the cylinder block 3. The matching relationship between the piston and the cylinder block is not shown here. Repeat; the inner cavity of the cylinder 3 is divided by the piston 6 into a working cavity 31 for outputting hydraulic pressure and a driving cavity 32 for inputting hydraulic pressure and driving the piston 6 to compress the working cavity 31. The direction of the arrow in the figure is the input and output. When working, the working chamber 31 and the driving chamber 32 are filled with working medium (hydraulic oil, etc.) to achieve the purpose of work; the piston 6 is provided with a piston rod 11 that extends out of the cylinder in the axial direction and outputs its mechanical stroke, The piston 6 compresses the working cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com