Split piston type linkage brake valve and motorcycle

A technology of piston type and brake valve, which is applied to motorcycles, motor vehicles, bicycle brakes, etc., can solve the problems of small braking deceleration, difficult manufacture, low braking sensitivity and precision, etc., and achieve increased braking Effects of deceleration, guaranteed service life, and shortened braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

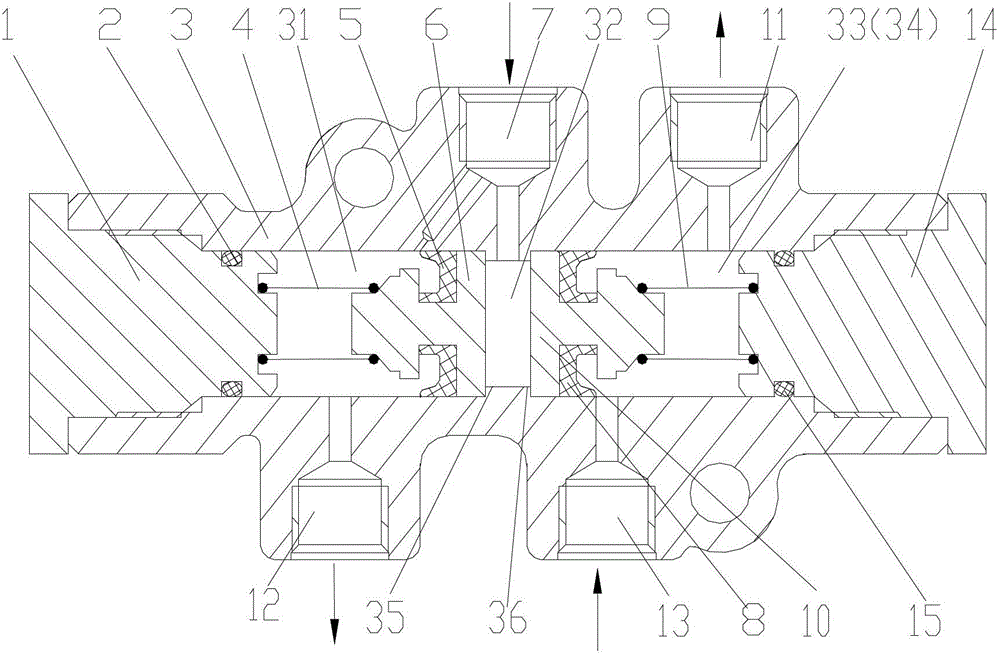

[0019] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the split-piston linkage brake valve of this embodiment includes a valve body and a valve core located in the valve body and slidingly fitted with the valve body in the axial direction. Independent piston I6 and piston II10, the inner chamber of the valve body 3 is separated by piston I6 and piston II10 into working chamber I31 and working chamber II33 for hydraulic output and a chamber for inputting hydraulic pressure to drive piston I6 and piston II10 to move axially. The hydraulic pressure output by the working chamber I31 and the working chamber II33 corresponds to the output braking force respectively, and the piston I6 and the piston II10 are respectively provided with a pretightening force opposite to the braking stroke; the return means that the piston I6 and the piston Ⅱ10 moves back from the working state to the normal state, and is driven back to the original posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com