Body structure of a motor vehicle, motor vehicle and method of manufacturing a body structure

A body and automobile technology, applied in the superstructure, superstructure sub-assemblies, special positions of vehicles, etc., to achieve the effect of reducing noise and wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

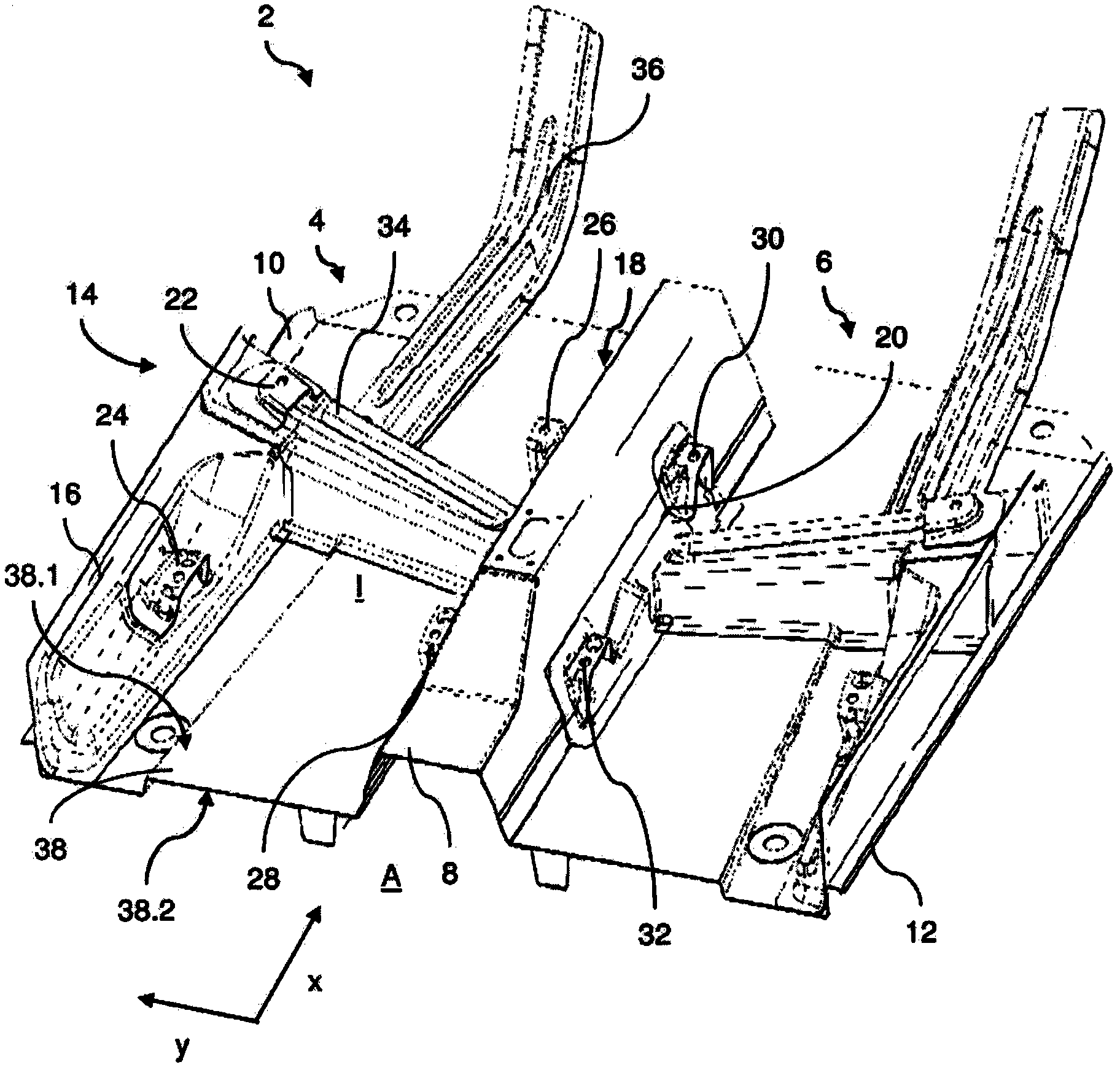

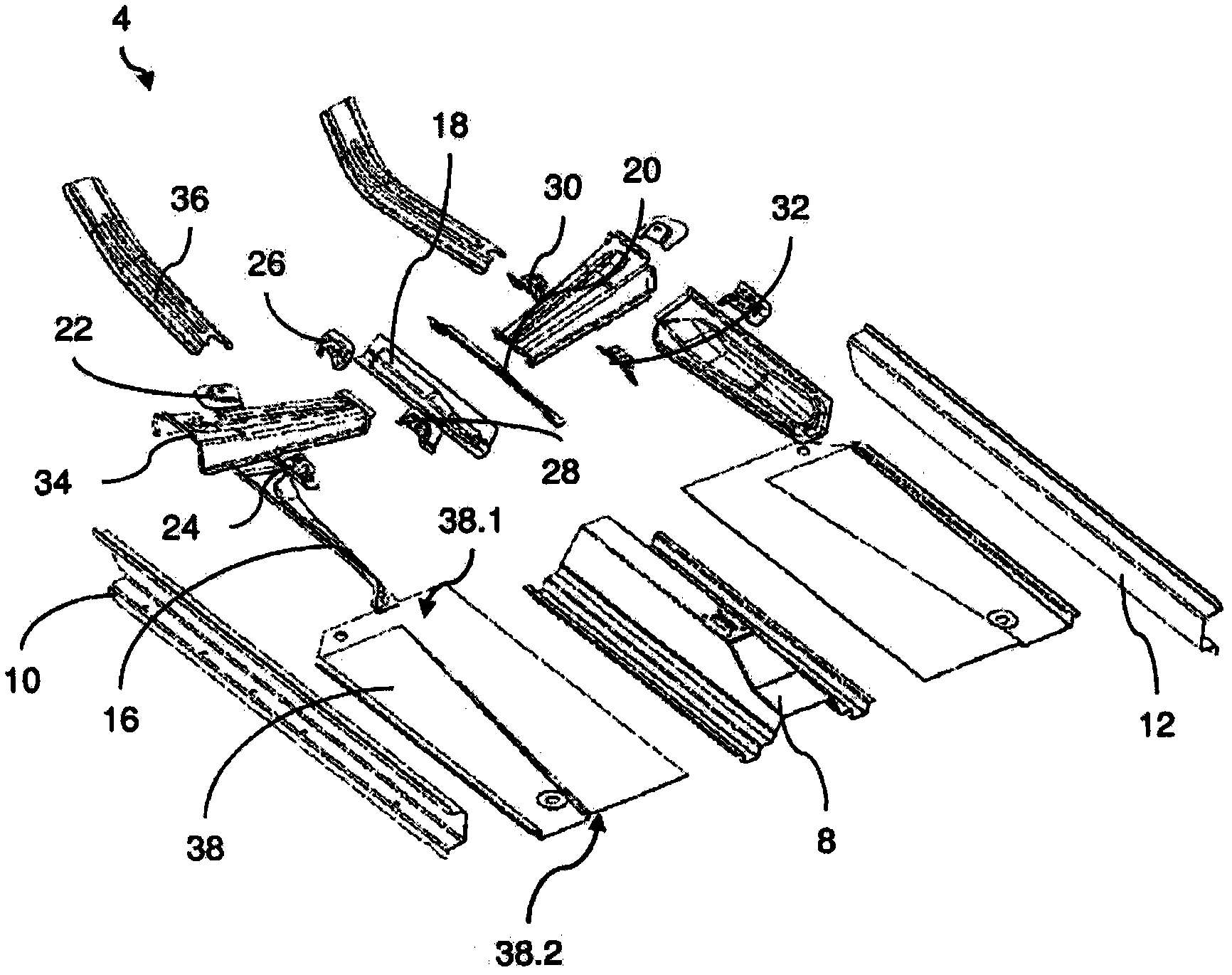

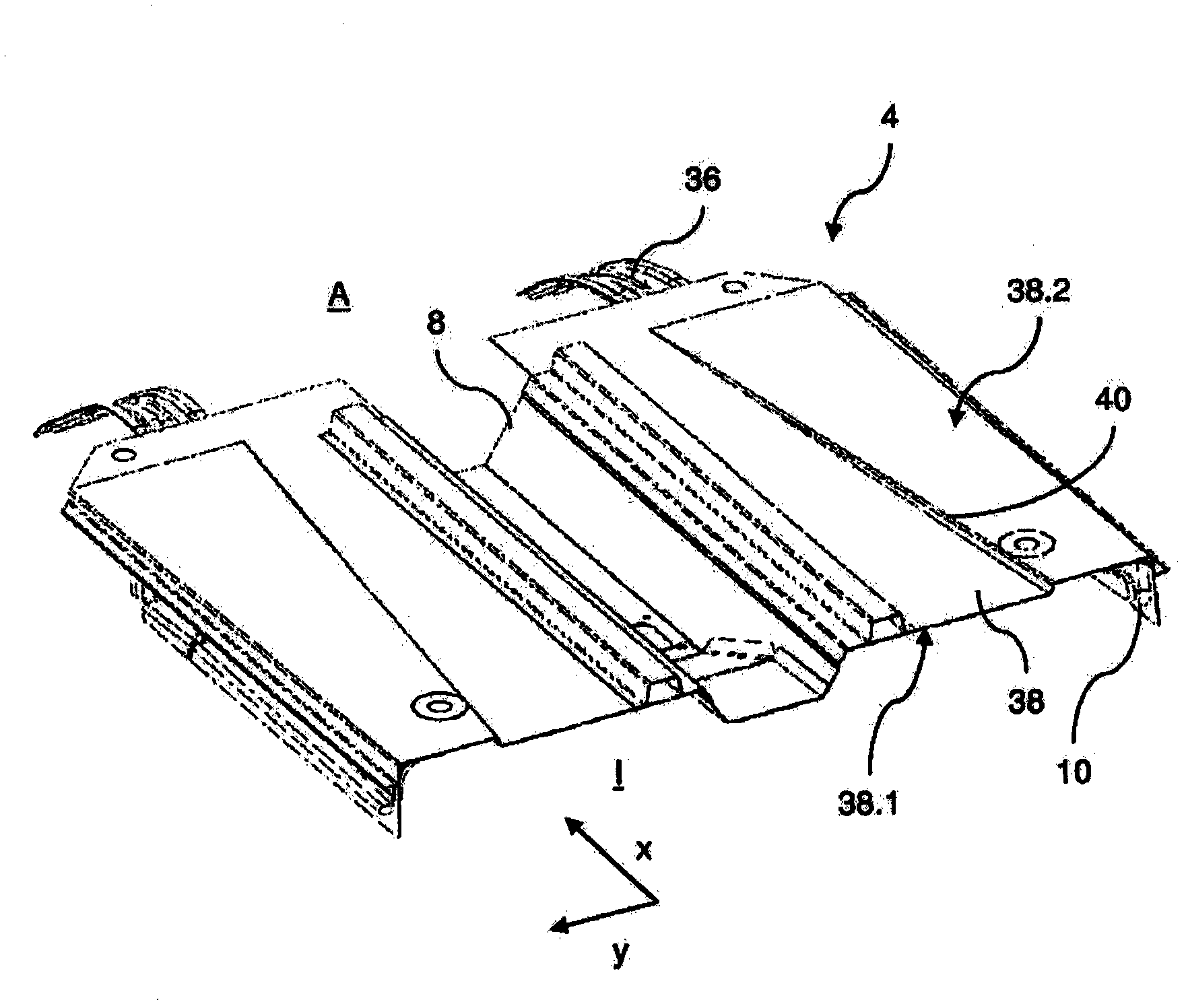

[0035] figure 1 A perspective view shows a part of a bottom structure 2 with two body structures 4, 6 according to the invention.

[0036] The body structures 4, 6 are combined into the bottom structure 2 shown by the middle bottom groove 8 and the side sills 10, 12 and other components.

[0037] The longitudinal direction of the car is represented by x, and the lateral direction of the car is represented by y.

[0038] Here, the present invention will be explained with the help of the body structure 4 on the left side, and the body structure 6 on the right side and the body structure 4 on the left side are mirror-symmetrical.

[0039] The vehicle body structure 4 according to the present invention has a seat fastening device 14. The seat fastening device 14 has a seat frame 16 arranged on the outside and a seat frame 18 arranged on the inside. figure 1 The middle (seat support 18) is covered, but is mirror-symmetrical to the seat support 20. The seat supports 16, 18, and 20 each hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com