Low density explosive and preparation method thereof

A technology for low-density explosives, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of low detonation ability and unstable detonation performance of low-density explosives, and achieve excellent physical and chemical properties, The effect of high strength and high detonation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The present embodiment provides a kind of preparation method of low-density explosives, comprising the following steps: 1) sequentially adding hydroxyl-terminated polybutadiene, diisooctyl sebacate, toluene diisocyanate, tris-(2-methylaziridine ) Phosphine oxide, dibutyltin dilaurate, and silica hollow microspheres (HD-3) are evenly mixed to obtain an adhesive; 2) Polyhei-14 booster is added to the adhesive, mixed and stirred in a mixer, The rotating speed of the mixer is 15-20rpm, the stirring time is 15-20min, and the mixture is obtained; 3) the mixture is poured, and finally solidified, the curing temperature is 18-30°C, the humidity is 40-70%, and the time is 48~ 60h.

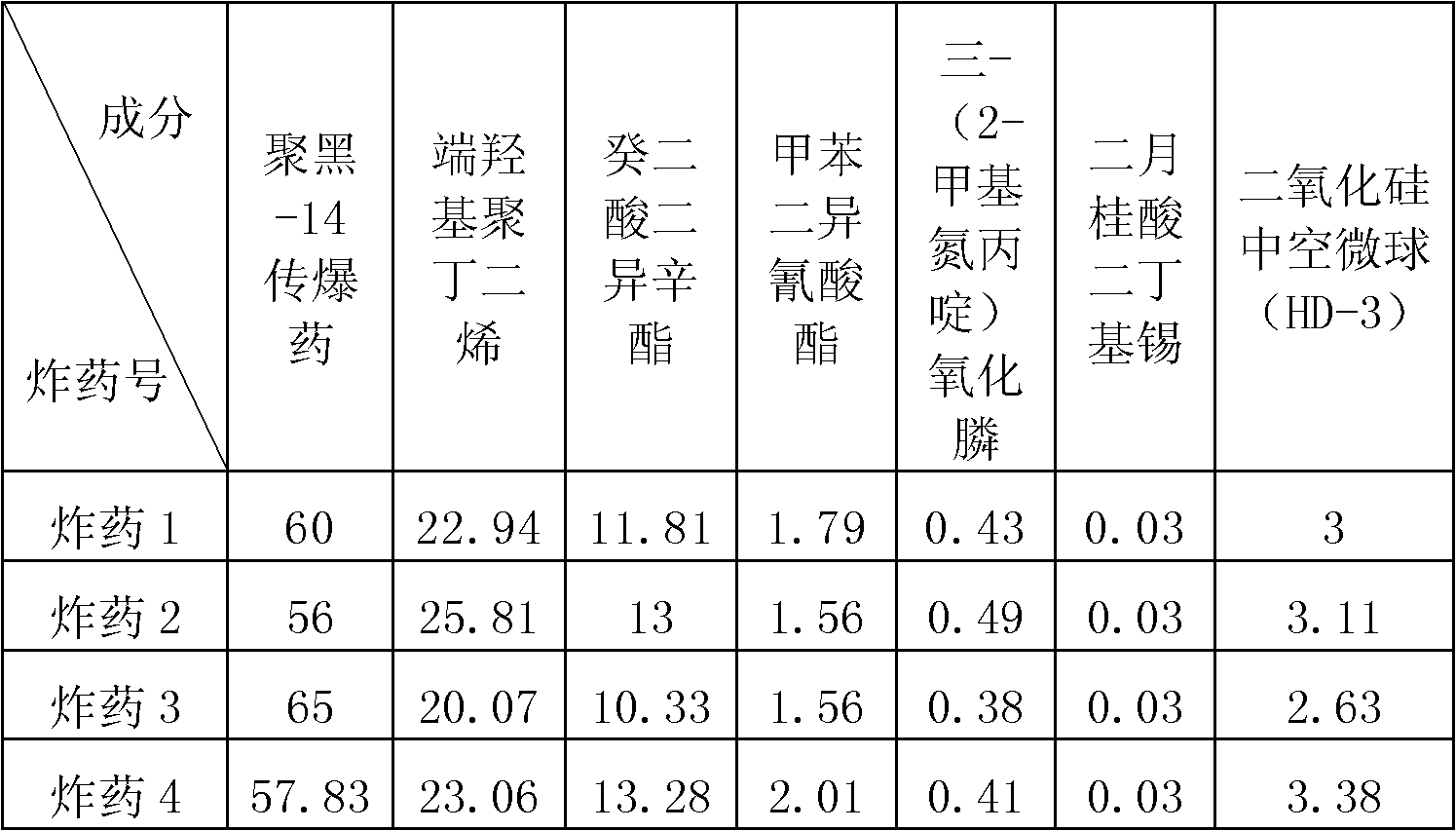

[0019] The low-density explosive of Example 1 was prepared by the preparation method, and the weight percentage of each component in the explosive was shown in Explosive 1 in Table 1.

Embodiment 2

[0021] The low-density explosive of Example 2 was prepared by the preparation method, and the weight percentage of each component in the explosive was shown in Explosive 2 in Table 1.

Embodiment 3

[0023] The low-density explosive of Example 3 was prepared by the preparation method, and the weight percentage of each component in the explosive was shown in Explosive 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com