High-temperature-resistant nuclear-shell structure type flame retardant, and preparation method and application thereof

A core-shell structure, high temperature resistant technology, applied in the field of materials to achieve the effects of good compatibility, high flame retardant efficiency, and increased reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

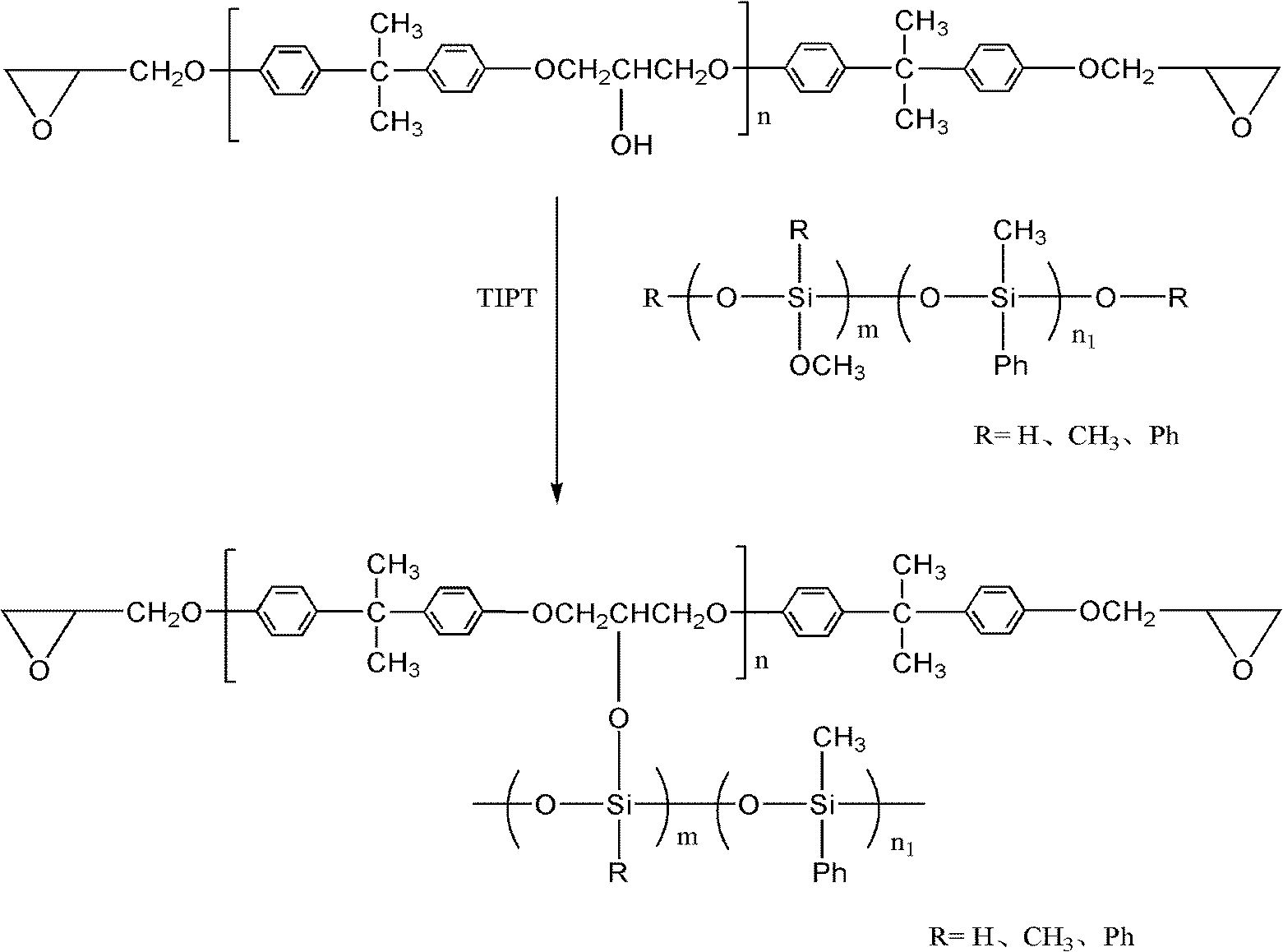

[0042] (1) Preparation of polymethylphenylsiloxane modified epoxy resin: In a four-necked round-bottomed flask equipped with a mechanical stirrer, a thermometer, an addition funnel, and a reflux condenser, add 70 grams of bisphenol A type epoxy Resin E-44, after heating and thinning, add 30 grams of polymethylphenylsiloxane (DowCorning, DC3074) and 0.15 grams of tetraisopropyl titanate, and heat up to 130 ° C for 4 hours to obtain polymethylphenyl Silicone modified epoxy resin.

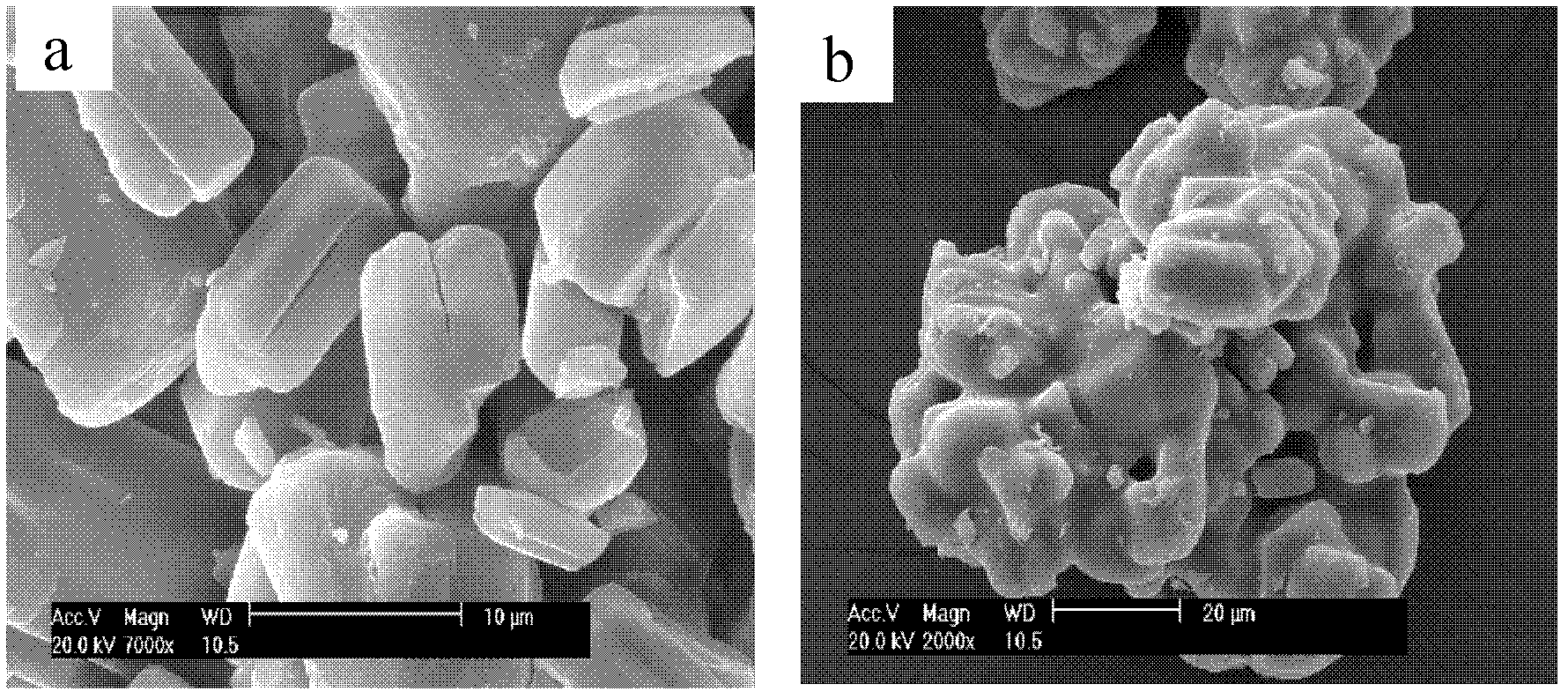

[0043](2) Preparation of flame retardant: 80 grams of ammonium polyphosphate (APP) was mechanically stirred and uniformly dispersed in 200 ml of absolute ethanol solution. Add 20 grams of the polymethylphenylsiloxane-modified epoxy resin prepared in step (1) at 25°C, and slowly raise the temperature (the heating rate is 3°C / min), and slowly add it dropwise (30 minutes) to dissolve Ethanol solution (20ml ) (curing agent consumption is 0.38 times of epoxy resin quality, is about to dissolve the curing...

Embodiment 2

[0046] (1) Preparation of polymethylphenylsiloxane modified epoxy resin: same as step (1) of Example 1.

[0047] (2) Preparation of flame retardant: same as Example 1 step (2), but with xylene as the dispersion system, and in the process of microencapsulation, add dropwise the xylene solution (20ml) that has dissolved the equivalent m-phenylenediamine .

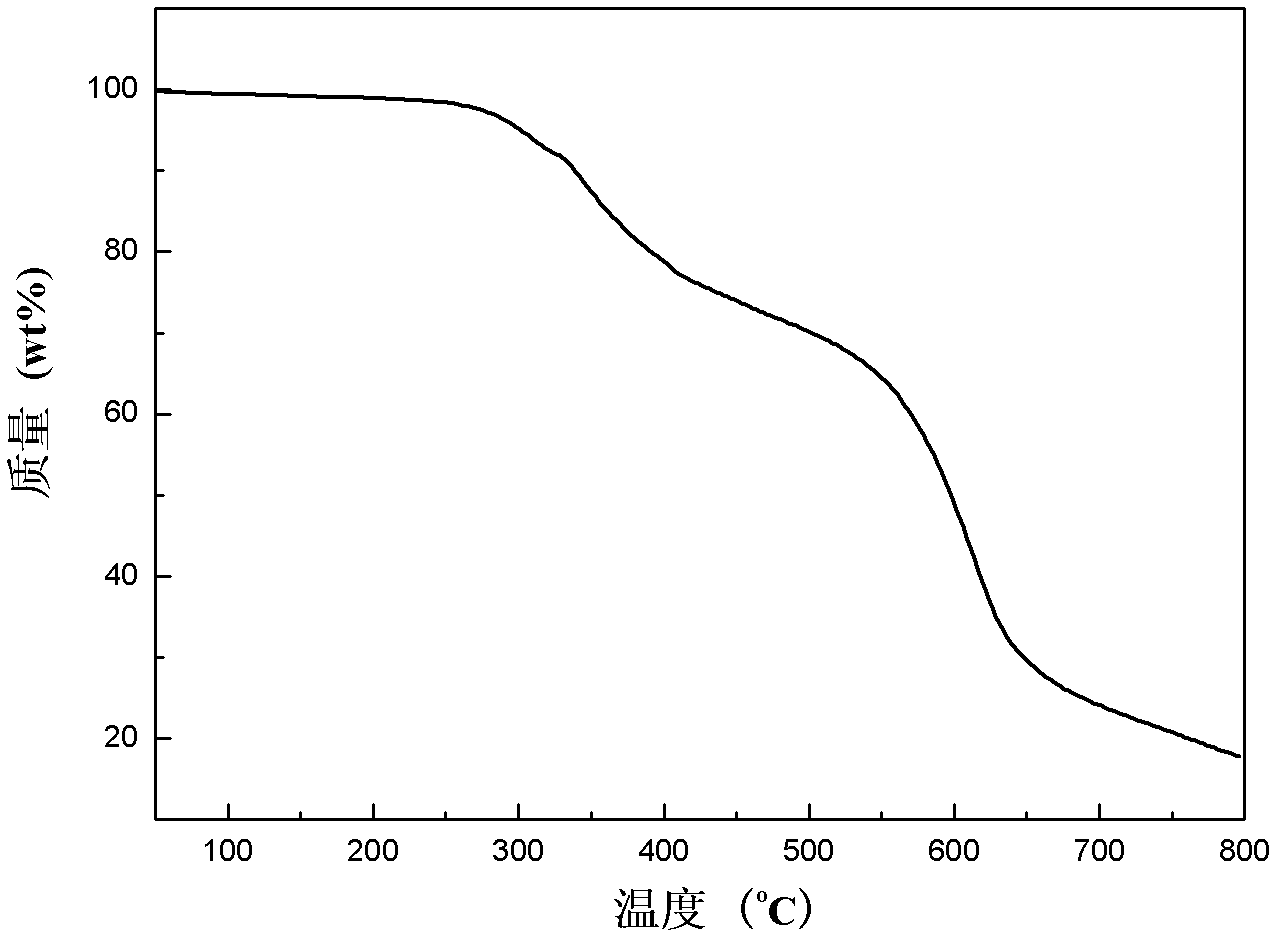

[0048] The solubility of the obtained product at 25°C is 0.06g / 100mlH 2 O. The flame retardant composite material was prepared by blending the flame retardant with the addition amount of 30% by mass with polypropylene, and the oxygen index was 27.5%. And after immersing the composite material in hot water at 50°C for 24 hours, the oxygen index of the material is 26.5%.

Embodiment 3

[0050] (1) Preparation of polymethylphenylsiloxane modified epoxy resin: same as step (1) of Example 1.

[0051] (2) Preparation of flame retardant: same as step (2) of embodiment 1, but the quality of APP is 60 grams.

[0052] The solubility of the obtained product at 25°C is 0.05g / 100mlH 2 O. The flame retardant composite material was prepared by blending the flame retardant with the addition amount of 30% by mass with polypropylene, and the oxygen index was 26.5%. And after soaking the composite material in hot water at 50°C for 24 hours, the oxygen index of the material is 25.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com