Novel machine needle protective cover special for sewing machine

A technology for sewing machines and shields, which is applied in the direction of sewing machine protection devices, sewing machine components, sewing equipment, etc., which can solve problems such as occlusion, and achieve the effects of increasing safety, ensuring operability, and saving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

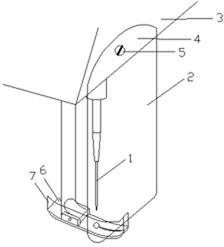

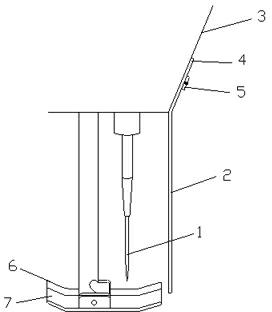

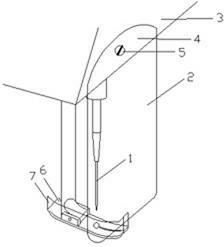

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0017] Such as figure 1 with figure 2 As shown, a main shield is fixed on the side of the sewing machine needle (1) facing the operator, the main shield body (2) is a vertical plate, and a connecting plate (4) is arranged on the upper end of the main shield body (2) ), the connecting plate (4) is parallel to the side (3) of the machine head facing the operator, the plane of the connecting plate (4) is close to the side (3) and is rotatably connected to it by a screw (5). The surface edge of the presser foot (6) is connected with a vertical thin plate to form a secondary shield (7), and the height of the thin plate is 0.8-1cm. The main shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com