Pipeline cutting device with chip removing function for water conservancy construction

A technology for pipe cutting and tools, which is applied in the direction of sawing machine accessories, manufacturing tools, sawing machine devices, etc. It can solve the problems of no adjustment of cutting angle, affecting machine operation, affecting the construction environment, etc., and achieves the effect of reasonable location and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

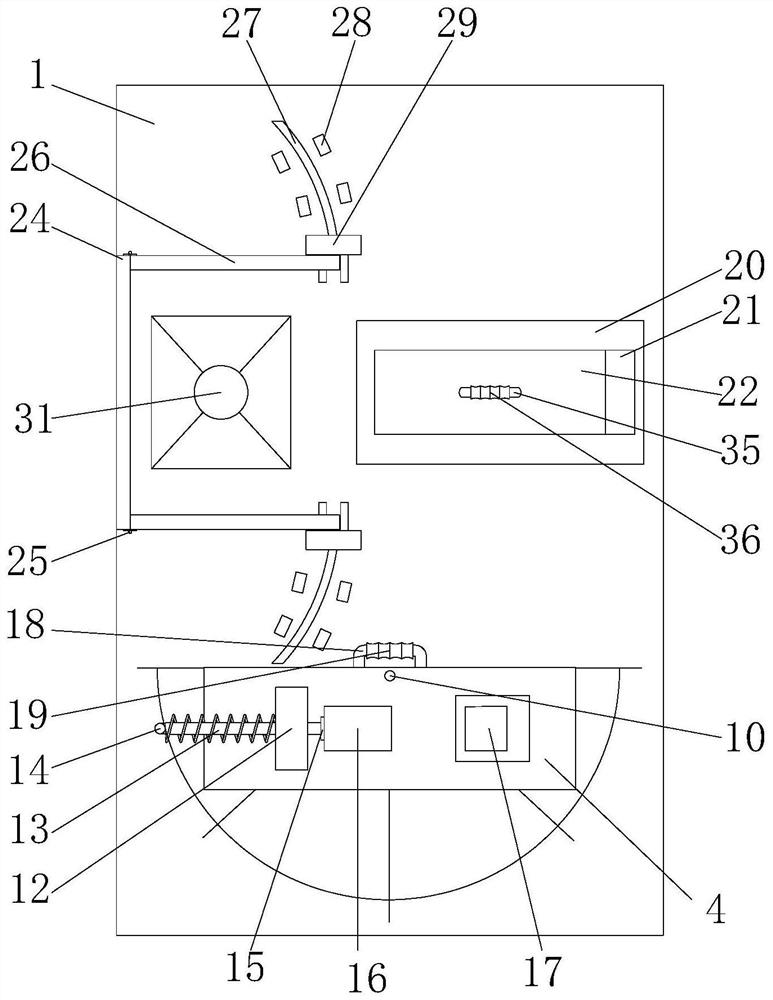

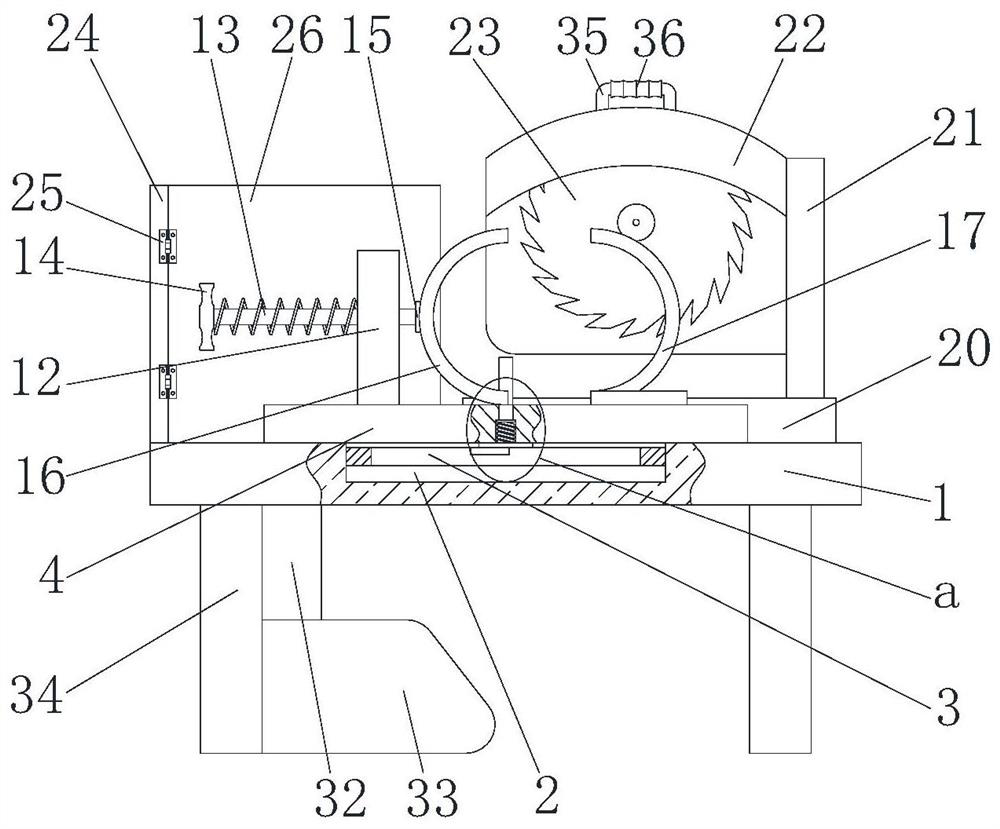

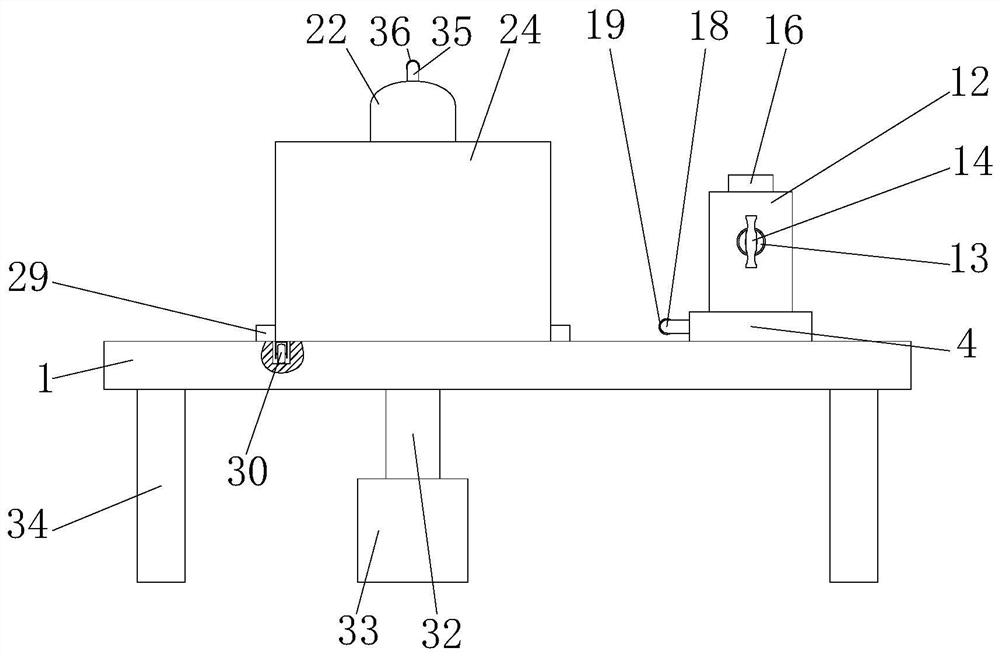

[0029] see Figure 1-6 As shown, a pipeline cutting device with chip removal function for water conservancy construction includes a table board 1, an adjustment mechanism, a collection mechanism and a cleaning mechanism. Support legs 34 are fixedly installed at the four corners of the bottom of the table board 1, and the table board 1 The top of 1 is fixedly installed with cutting machine body, and cutting machine body comprises base 20, connecting frame 21, protective frame 22 and sawtooth 23, and base 20 is fixedly installed on the top of table board 1, and connecting frame 21 is connected with rotation on base 20, connects One side of frame 21 is fixedly installed with protective frame 22, is provided with sawtooth 23 in protective frame 22, and the top of protective frame 22 is fixedly installed with second handle 35, and second handle 35 is fixedly sleeved with second handle 36, and table The top surface of the plate 1 is rotated and installed with a mounting plate 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com