Protective covers for blast furnace cooling plate assemblies

A technology of cooling plate and protective cover, applied in the direction of cooling device, etc., can solve the problems of large temperature difference inside and outside the furnace shell 10, the degree of welding seam cracking becomes larger, and the welding seam cracking, etc., to enhance the cooling effect, easy to adjust, and slow down the welding seam. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

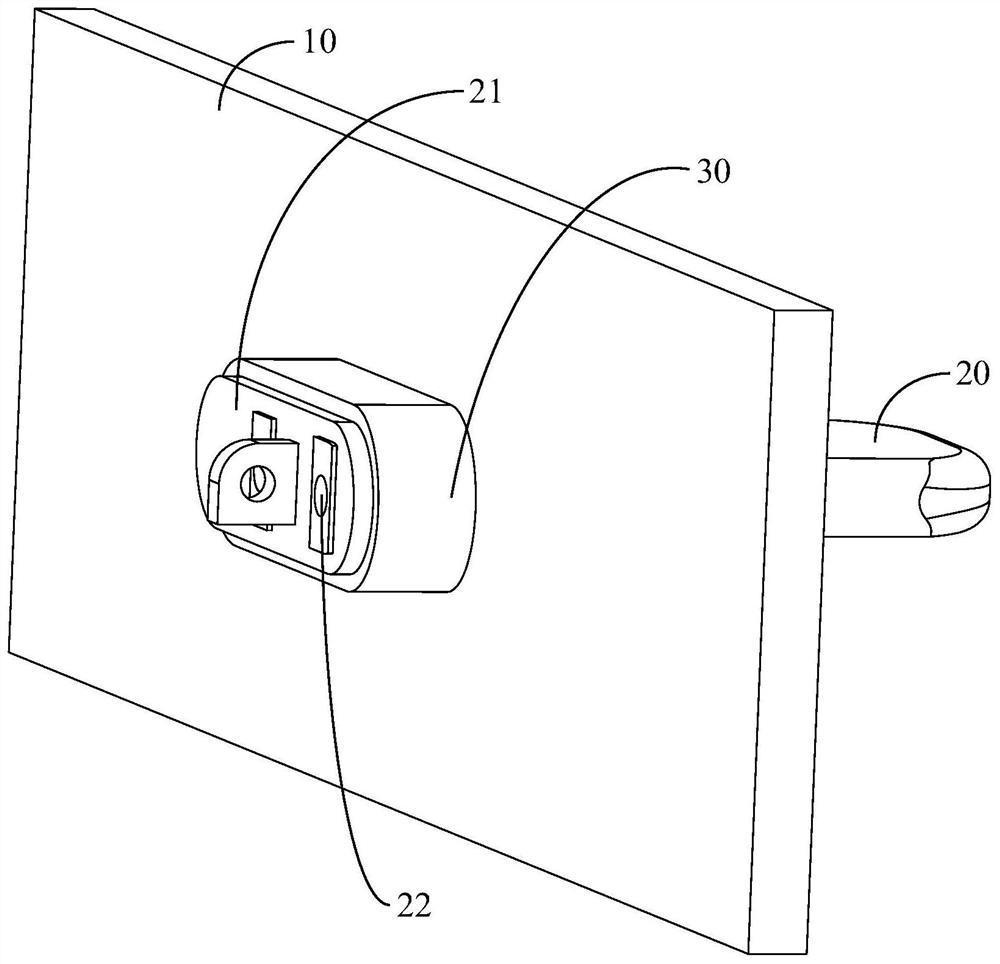

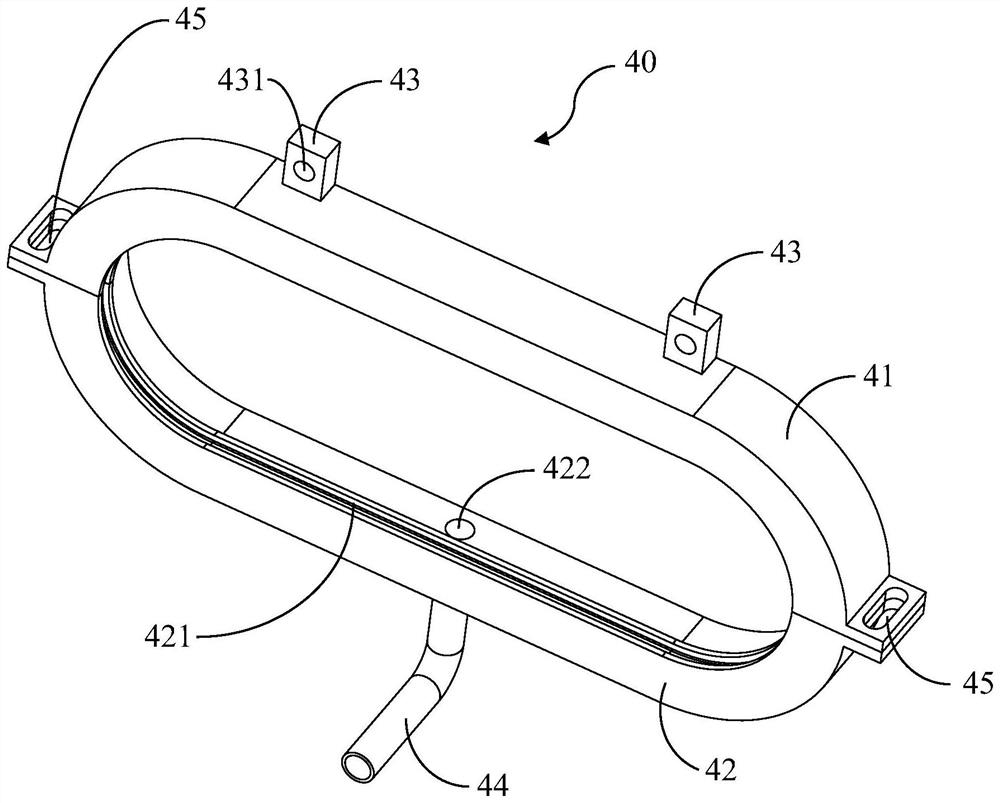

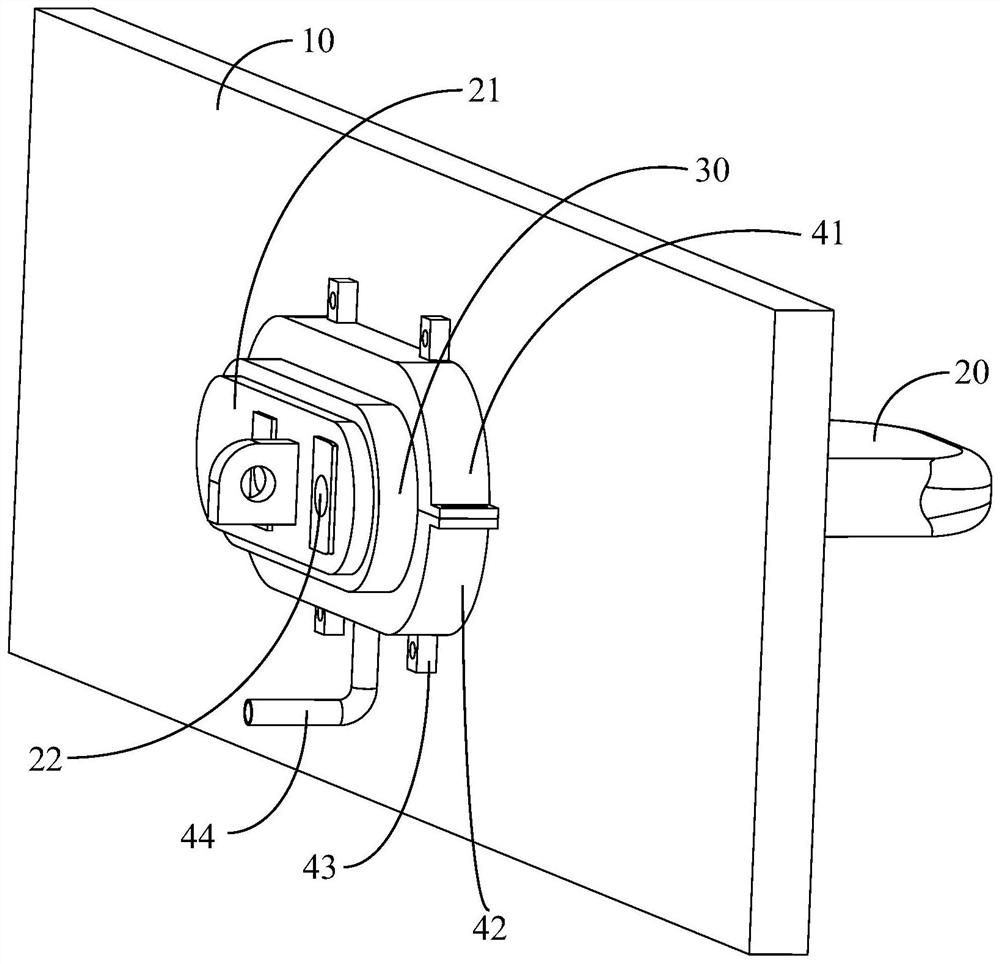

[0022] see figure 2 and combine image 3 , the protection cover 40 used for the blast furnace cooling plate assembly of the present invention is sleeved on the outside of the casing 30 and installed on the furnace shell 10 , wherein the gap fit between the protection cover 40 and the casing 30 . Once the weld seam between the sleeve pipe 30 and the furnace shell 10 cracks, pressure flames and red spatters are ejected, the protective cover 40 can suppress the pressure flames and prevent the red spatters from flying out. Since the plurality of cooling plates 20 on the furnace shell 10 are connected by piping, in order to facilitate the disassembly of the protective cover 40, the protective cover 40 can be made into a split structure. As a method, the protective cover 40 includes an upper cover 41 and a lower cover. 42. The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com