Wood planing machine

A woodworking planer and planer technology, which is applied to wood processing appliances, manufacturing tools, and processing machines for manufacturing flat surfaces, etc., can solve problems such as the impact of mechanical life, the difficulty in collecting wood chips, and running everywhere, so as to reduce splashes and increase the effect. , increase the effect of driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

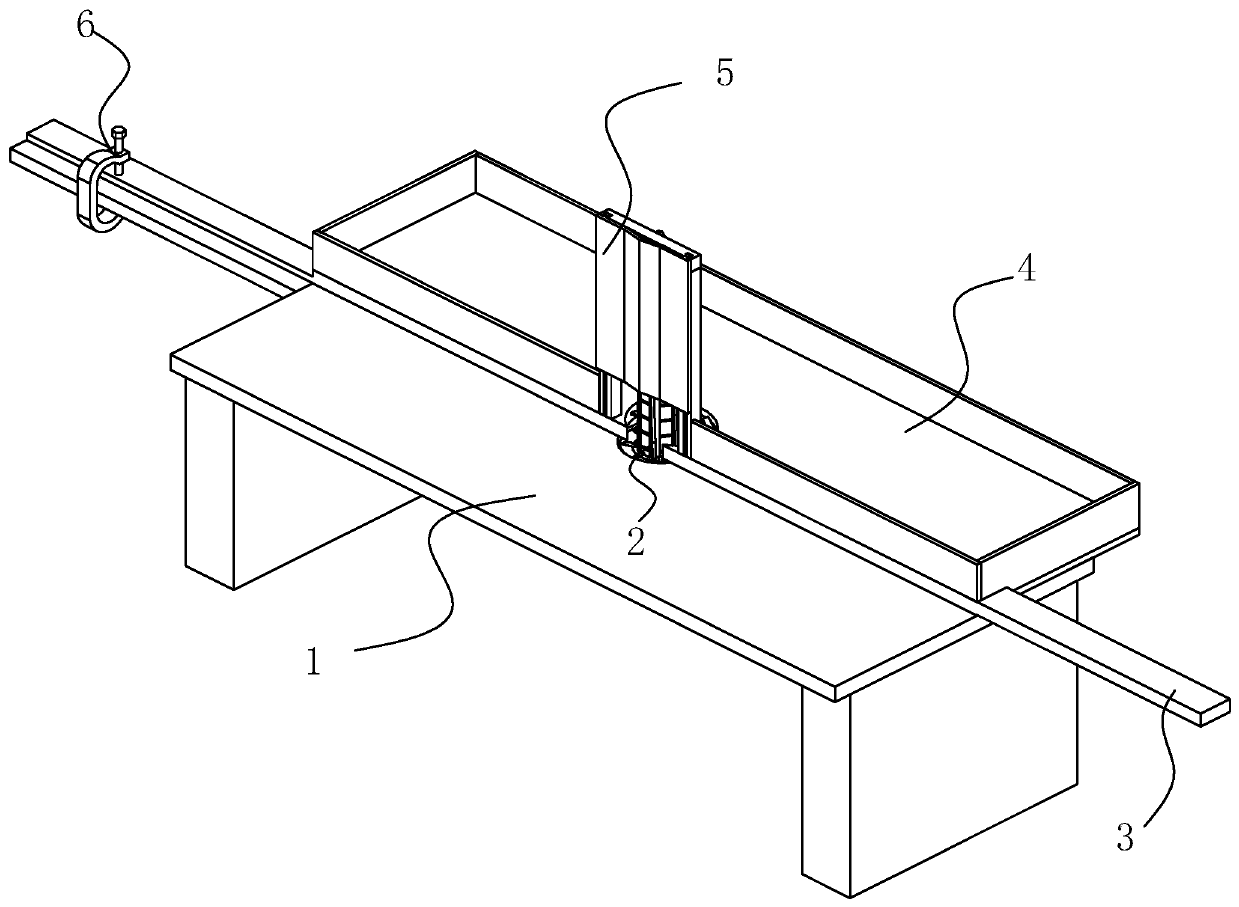

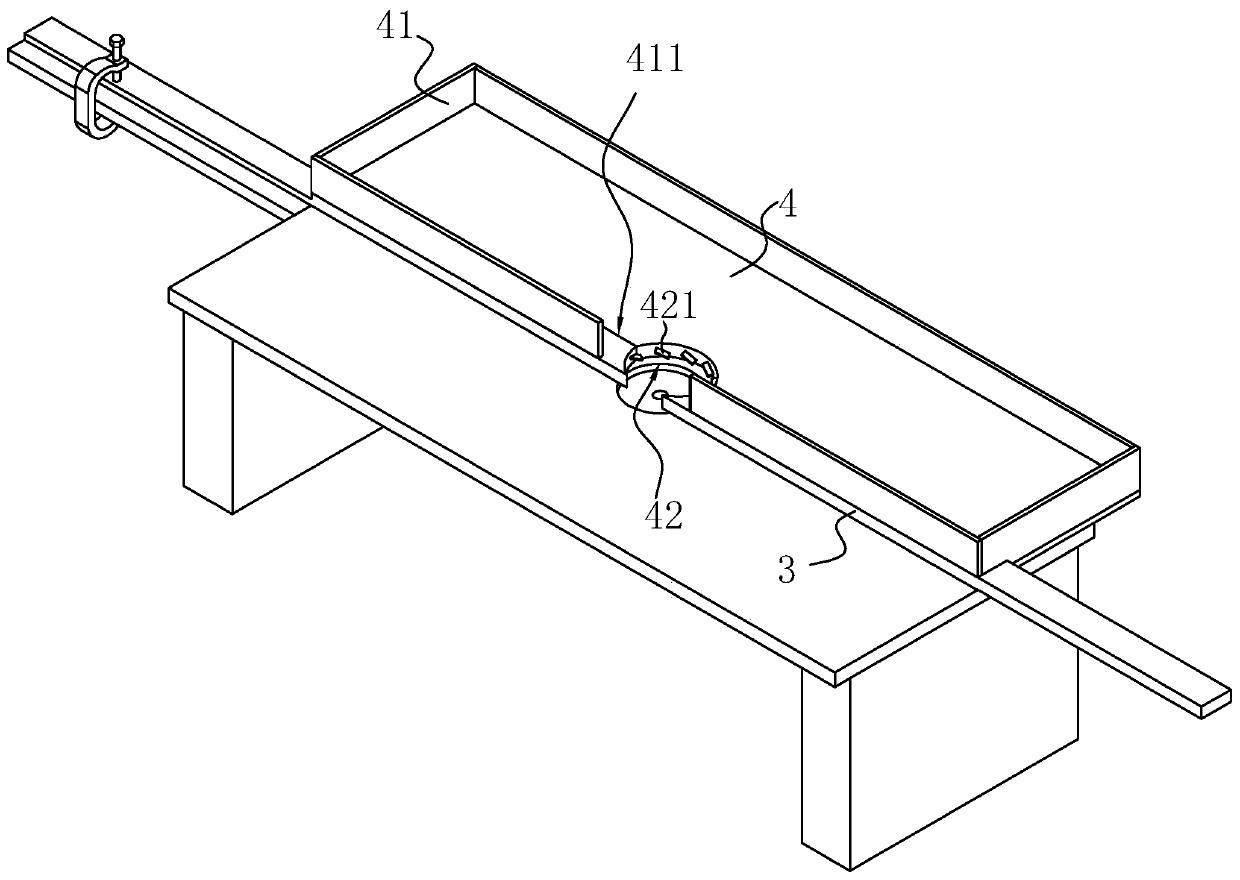

[0031] Embodiment: a kind of woodworking planer, participate in figure 1 , including a workbench 1, a processing device 2 arranged on the workbench 1 to process wooden strips, a guide plate 3 fixed on the top of the workbench 1, a material receiving plate 4 fixed on one side of the workbench 1, and a processing device arranged on the The protective assembly 5 on the 2 and the auxiliary assembly 6 on the guide plate 3. In order to adapt to wooden strips of different lengths, the two ends of the guide plate 3 stretch out from the workbench 1.

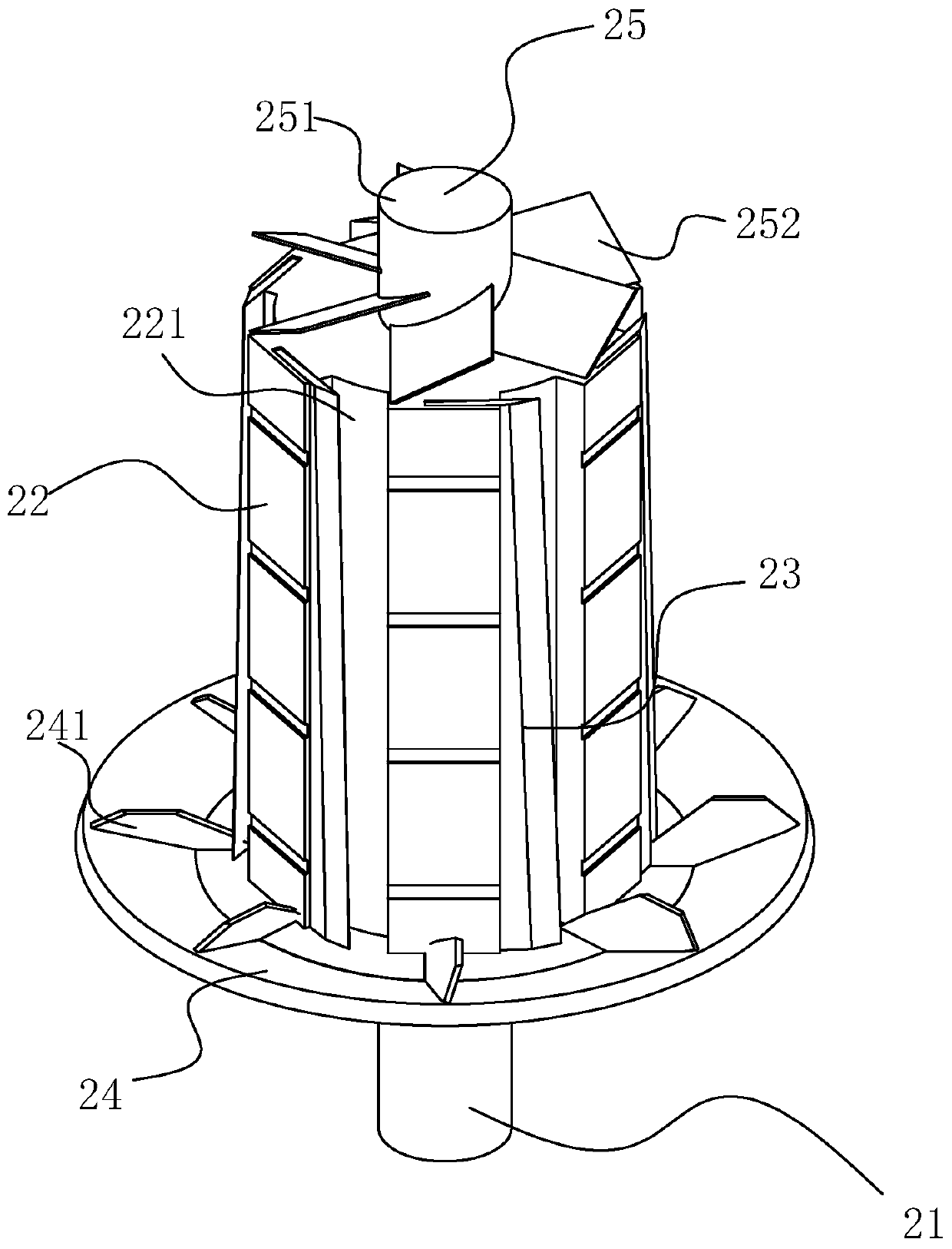

[0032] see figure 2 The processing device 2 includes a rotating shaft 21, a planer frame 22 coaxially rotating with the rotating shaft 21, a planer 23 arranged on the planer frame 22, a fixed plate 24 fixed at the bottom end of the planer frame 22, and an auxiliary part 25 arranged at the top end of the planer frame 22 .

[0033] The bottom end of the rotating shaft 21 passes through the workbench 1, and the bottom end of the workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com