Open channel bend flume testing device

A technology of water tank test and curve, applied in the direction of hydraulic model, etc., can solve problems such as inability to use light source or take pictures, large damage to side wall glass, large manpower and material resources, etc., and achieve important practical value in production, promotion and application prospects, and adaptability Strong, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

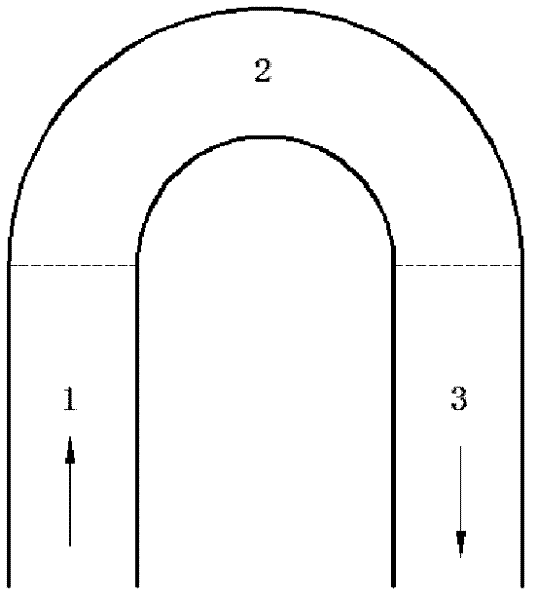

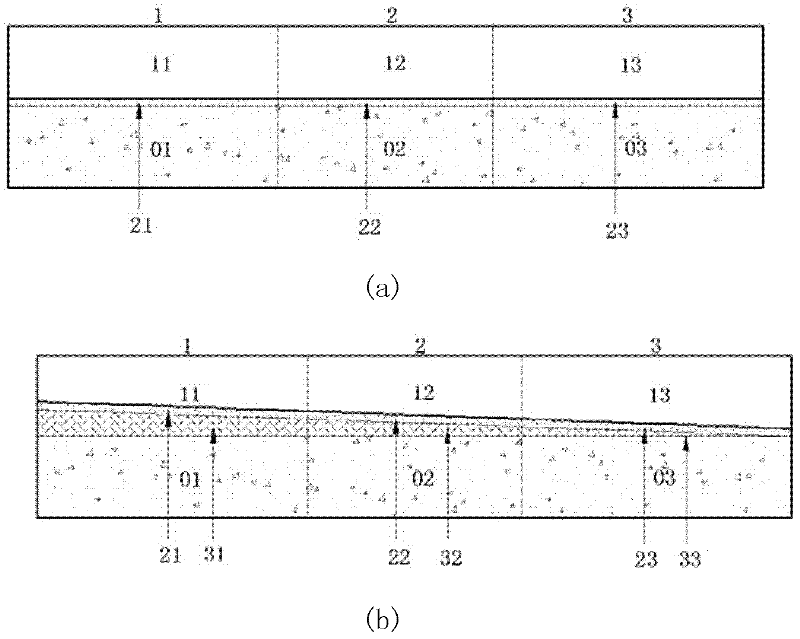

[0030] The overall structure of the open channel curved water tank test device of the present invention includes a lifting system, a main beam, a supporting frame, and an open channel curved water tank composed of a glass bottom plate and a glass side wall, wherein the open channel curved water tank is installed on the supporting frame, and the supporting frame Welded on the main beam, the lifting system is supported on the bottom of the main beam for continuous adjustment of the slope of the tank.

[0031] The specific implementation and function of each part of the above-mentioned device are described respectively as follows in conjunction with the accompanying drawings:

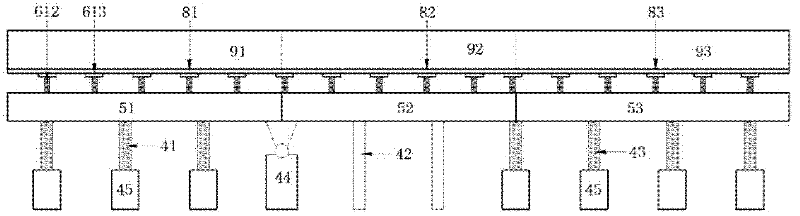

[0032] The main beam of this embodiment is welded into a frame structure with rectangular steel with a specification of 80×120×5mm, such as image 3 As shown, it is composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com