Liquid piston hydraulic-pneumatic engine

A liquid piston and engine technology, applied in the field of liquid piston liquid-gas engines, can solve the problems of large volume, small expansion space, occupying volume and weight, and achieve the effect of small volume, light weight and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

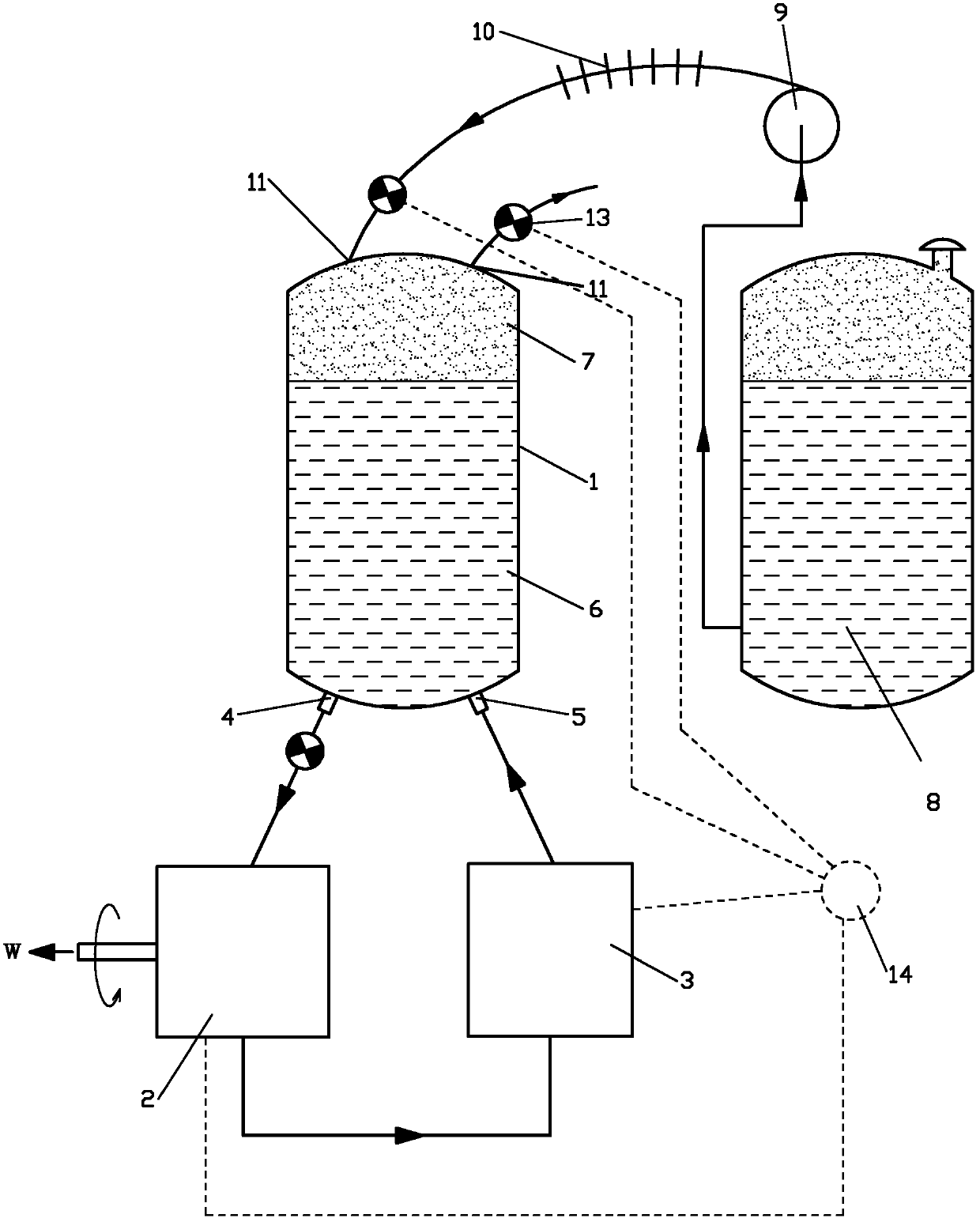

[0037] like figure 1 The liquid-piston liquid-pneumatic engine shown includes a gas-liquid cylinder 1, a hydraulic power mechanism 2, a liquid working medium return system 3 and a liquid gas source 8, and the liquid gas source 8 passes through a high-pressure liquid pump 9, liquid heat absorption and heat exchange successively. The device 10 communicates with the gas-liquid cylinder 1, and the liquid in the liquid gas source 8 is quantitatively introduced into the liquid heat-absorbing heat exchanger 10 and gasified in the liquid heat-absorbing heat exchanger 10 to form a gas work The gas working fluid 7 communicates with the gas-liquid cylinder 1 through the gas working fluid control valve 12 .

[0038]An exhaust port 11 is arranged on the gas-liquid cylinder 1, an exhaust control valve 13 is arranged at the exhaust port 11, a liquid working medium outlet 4 and a liquid working medium return port 5 are arranged on the gas-liquid cylinder 1, The liquid working medium outlet ...

Embodiment 2

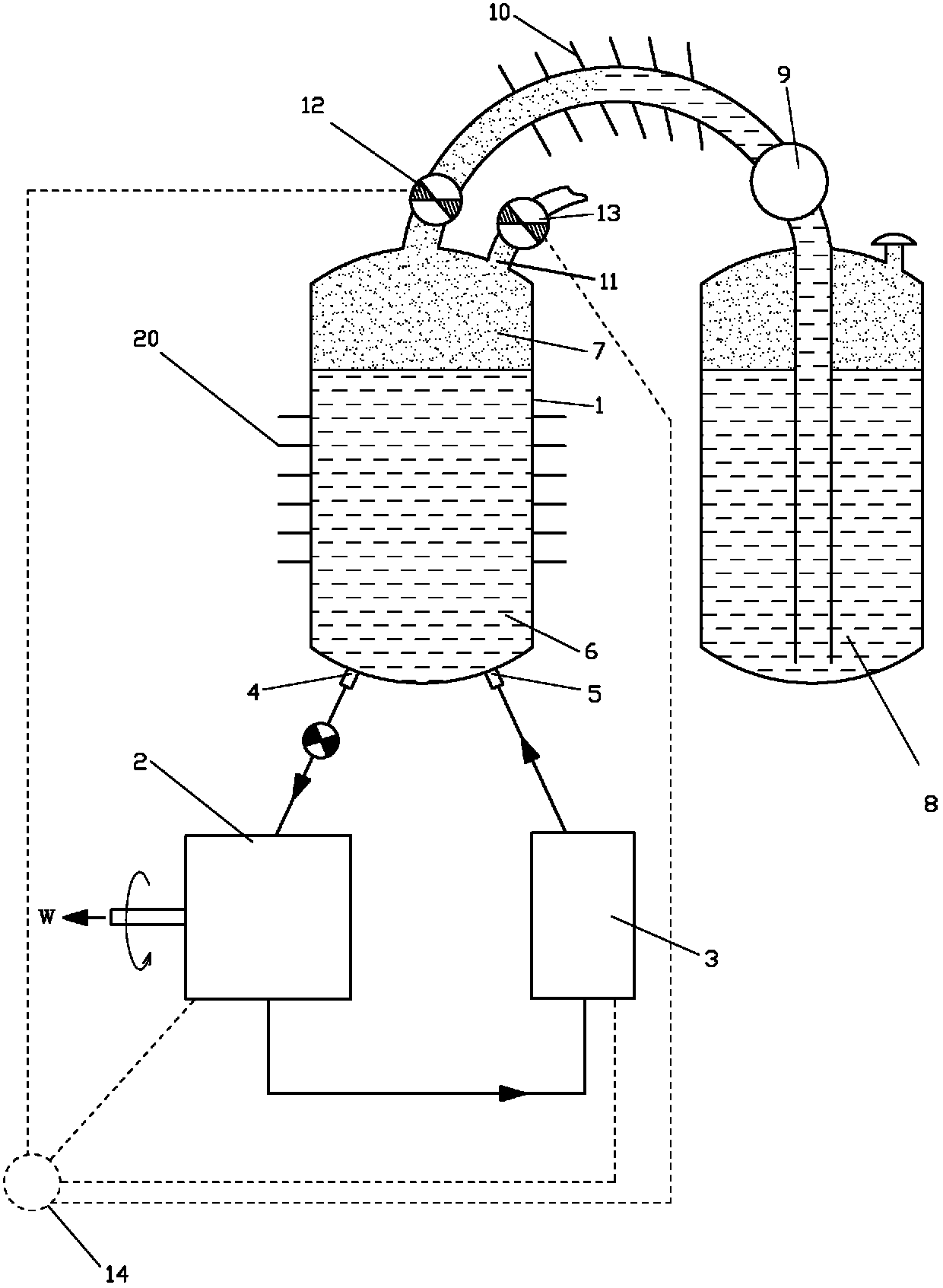

[0042] like figure 2 The difference between the shown liquid-piston liquid-gas engine and Embodiment 1 is that a gas-liquid cylinder working medium heat-absorbing heat exchanger 20 is arranged on the gas-liquid cylinder 1 .

Embodiment 3

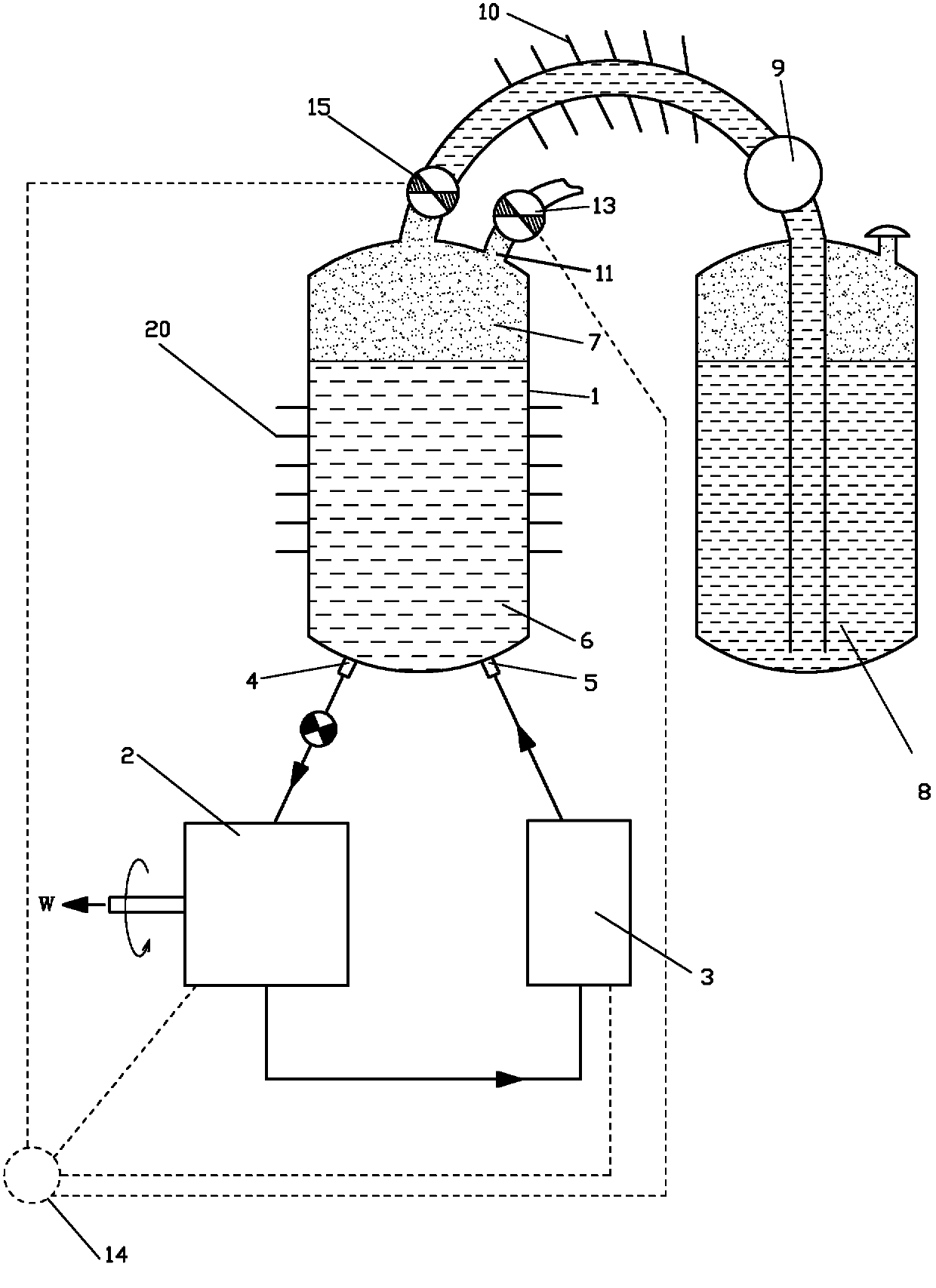

[0044] like image 3 The difference between the liquid-piston liquid-pneumatic engine shown in Embodiment 1 is that it includes a gas-liquid cylinder 1, a hydraulic power mechanism 2, a liquid working medium return system 3 and a liquid gas source 8, and the liquid gas source 8 passes through the The high-pressure liquid pump 9, the liquid heat-absorbing heat exchanger 10, and the liquid working medium control valve 15 are in communication with the gas-liquid cylinder 1, and the liquid in the liquid gas source 8 is quantitatively introduced into the gas-liquid cylinder 1 and released in the gas-liquid cylinder 1. The gas working fluid 7 is formed by gasification in the gas-liquid cylinder 1; a gas-liquid cylinder working fluid heat-absorbing heat exchanger 20 is arranged on the gas-liquid cylinder 1.

[0045] An exhaust port 11 is arranged on the gas-liquid cylinder 1, an exhaust control valve 13 is arranged at the exhaust port 11, a liquid working medium outlet 4 and a liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com