Method and device for detecting surface precision of dish parabolic reflecting mirror

A technology of parabolic reflectors and reflector surfaces, which is applied in the detection field of surface accuracy of dish parabolic reflectors, and can solve problems such as the inability to achieve high-precision and accurate measurement of the surface accuracy of dish-type parabolic reflectors, and lack of pertinence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

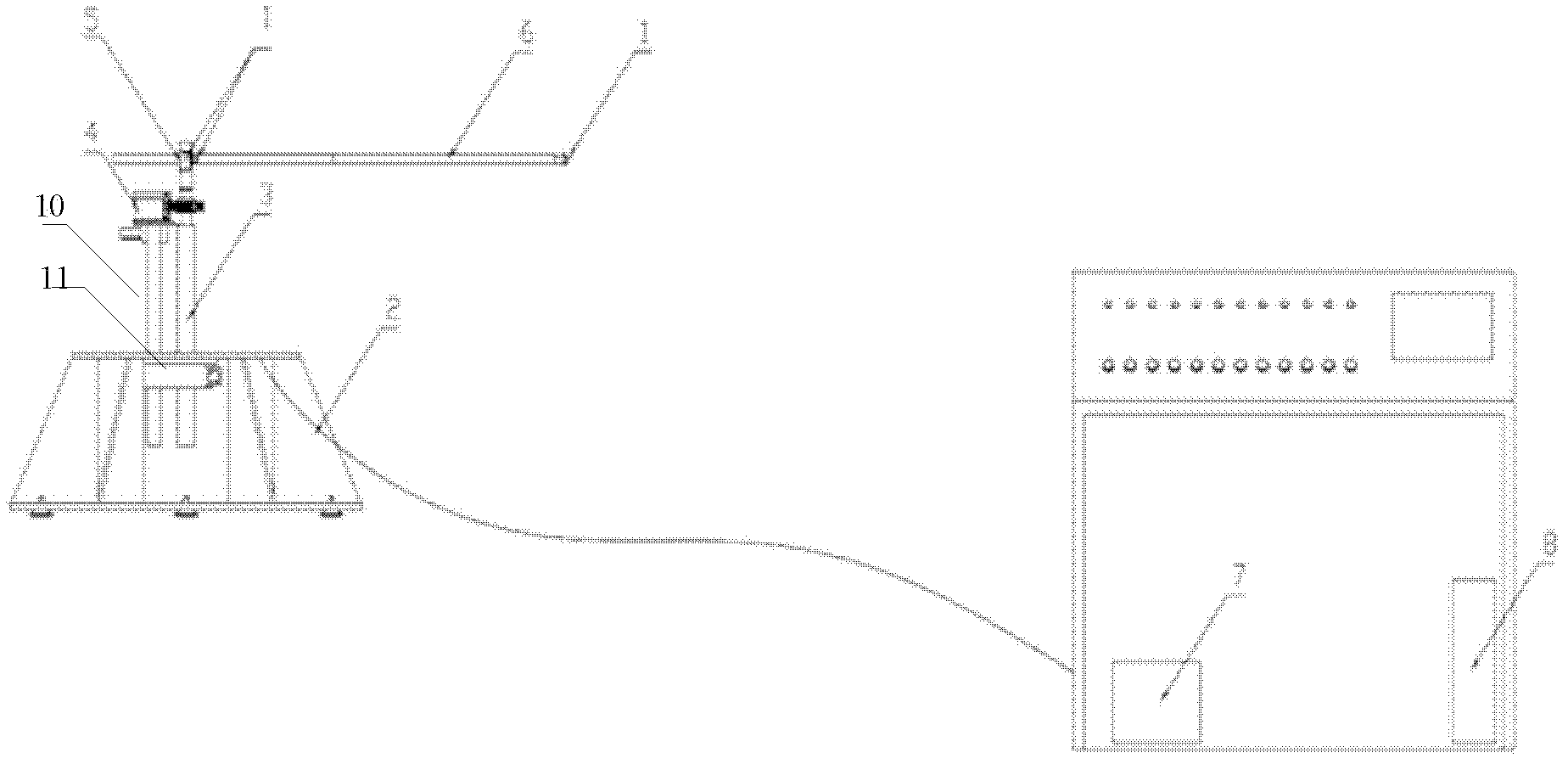

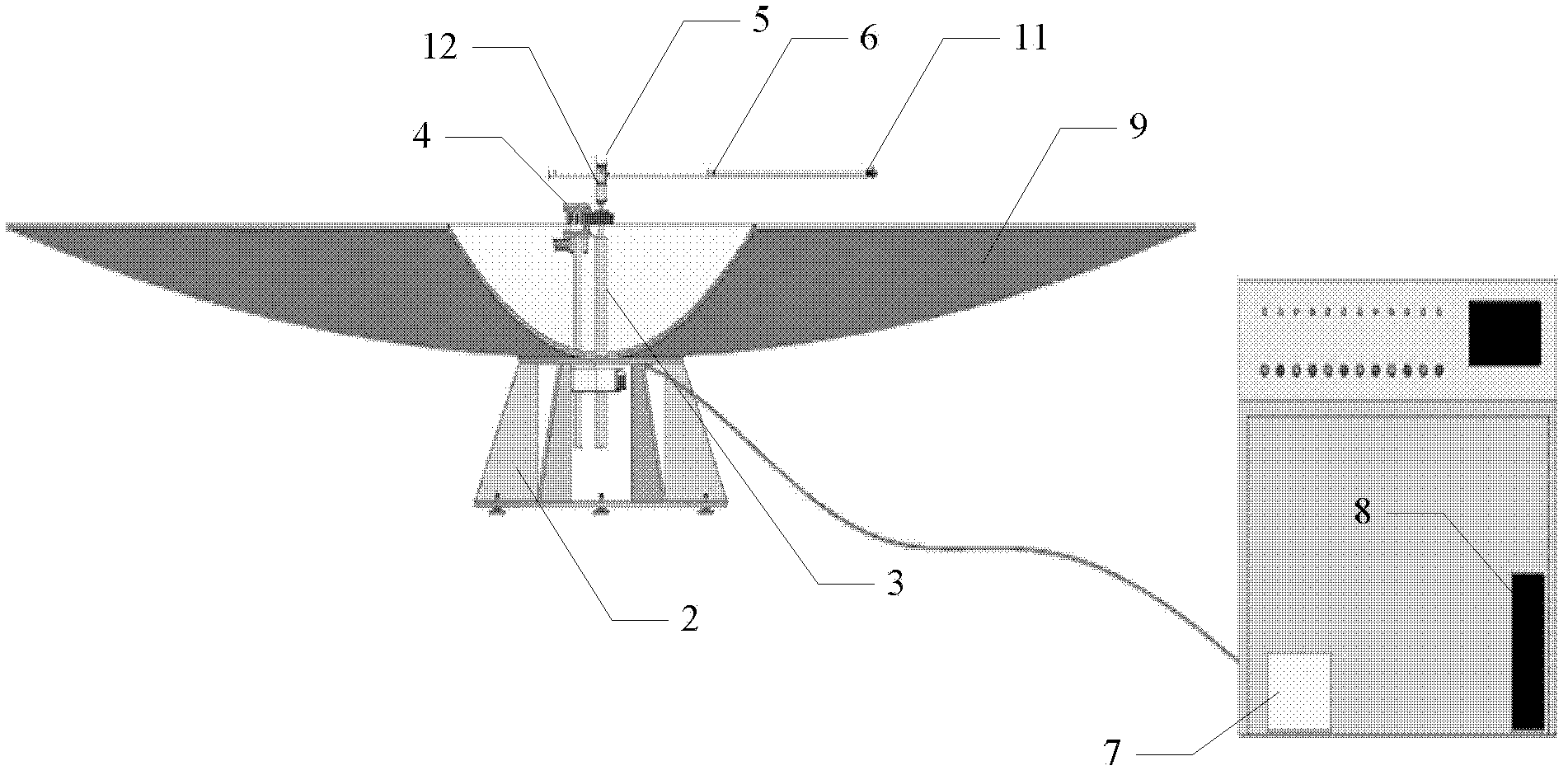

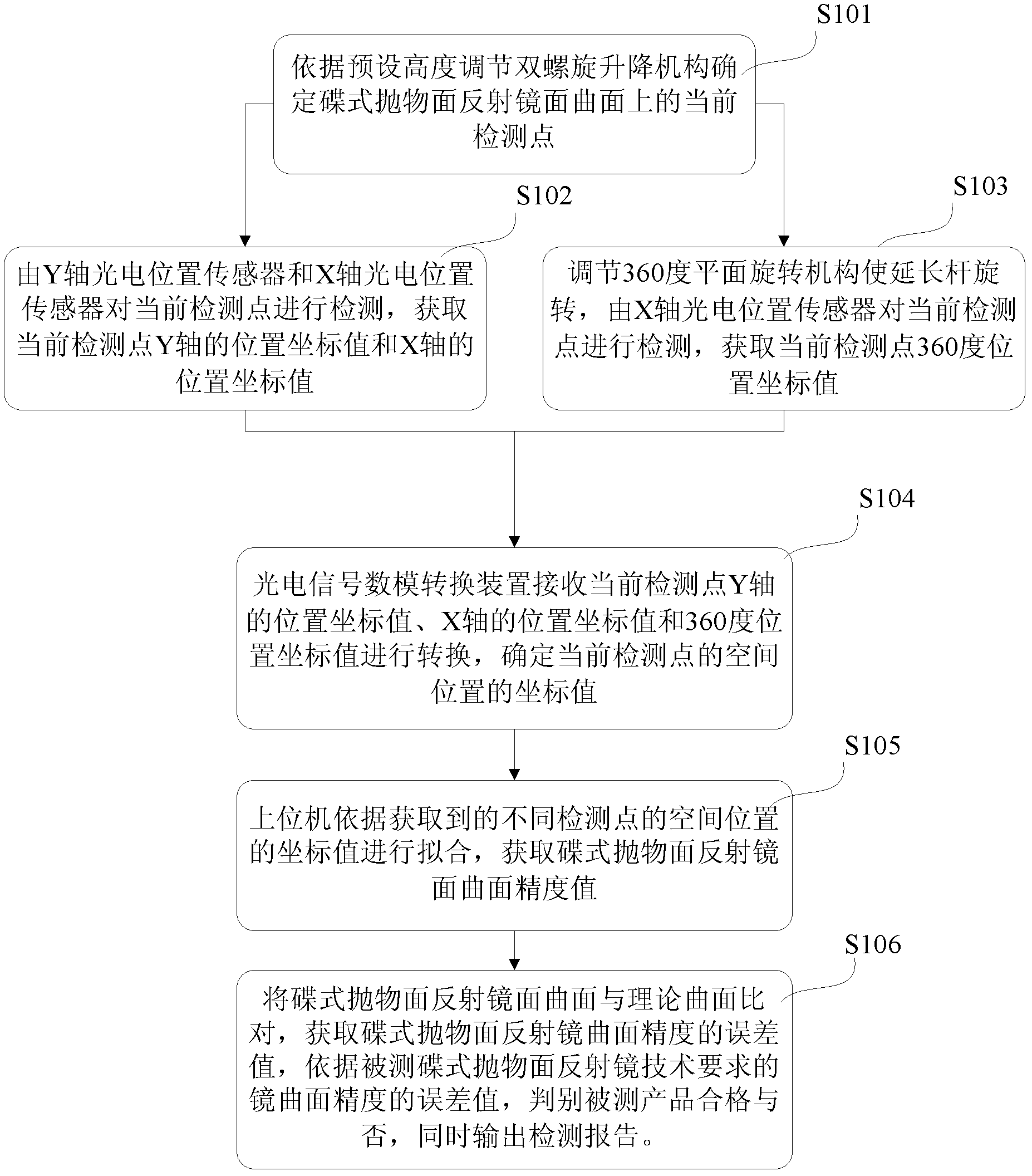

[0048] Please refer to the attached figure 1 , which is a structural schematic diagram of a detection device for the surface accuracy of a dish-type parabolic mirror disclosed by the present invention, mainly including: a photoelectric position sensor 1, a mounting support 2, a double-helix lifting mechanism 3, a 360-degree plane rotation mechanism 4, and a telescopic mechanism 5 , an extension rod 6, a photoelectric digital-to-analog conversion device 7 and a host computer 8.

[0049]The photoelectric position sensor includes: an X-axis photoelectric position sensor 11 for measuring the position coordinate value on the X-axis of each detection point and a 360-degree position coordinate value of each detection point, and an X-axis photoelectric position sensor 11 for measuring the position coordinate value of each detection point on the Y-axis. The Y-axis photoelectric position sensor 11 of the position coordinate value.

[0050] The top of the mounting support 2 can be insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com