Temperature compensator of Hall detection current sensor

A current sensor and temperature compensator technology, applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve problems such as instability, large indication deviation of measurement signals, inaccurate real current, etc., to meet the requirements of use, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The content of the present invention will be described below in conjunction with specific embodiments.

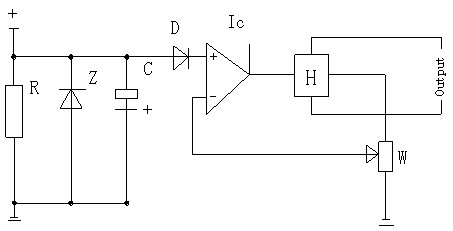

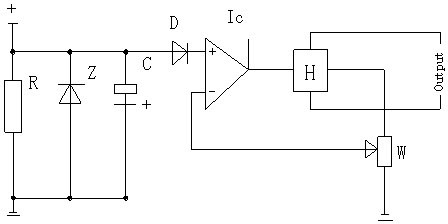

[0009] Such as figure 1 As shown, the temperature compensator described in this embodiment includes: a voltage stabilized source, a constant current source and a diode D, a diode D is connected in series between the voltage stabilized source and the constant current source, the voltage stabilized source is connected to the anode of the diode D, and the constant current source Connect to diode D cathode.

[0010] The diode D is placed in the same environment as the Hall element H, and the constant current source voltage excitation current change of the diode D is changed by the temperature change characteristics and the temperature change characteristics of the Hall element H are complementary to each other, so that the output of the Hall element H is not affected by the temperature change .

[0011] The voltage stabilizing source includes a resistor R, a diode Z, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com