Novel rotating travelling-wave ultrasonic motor

An ultrasonic motor, rotary type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the instability of ultrasonic motor, heavy local friction, affecting ultrasonic motor Work performance and service life and other issues, to achieve the effect of improving the maximum output torque and efficiency, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

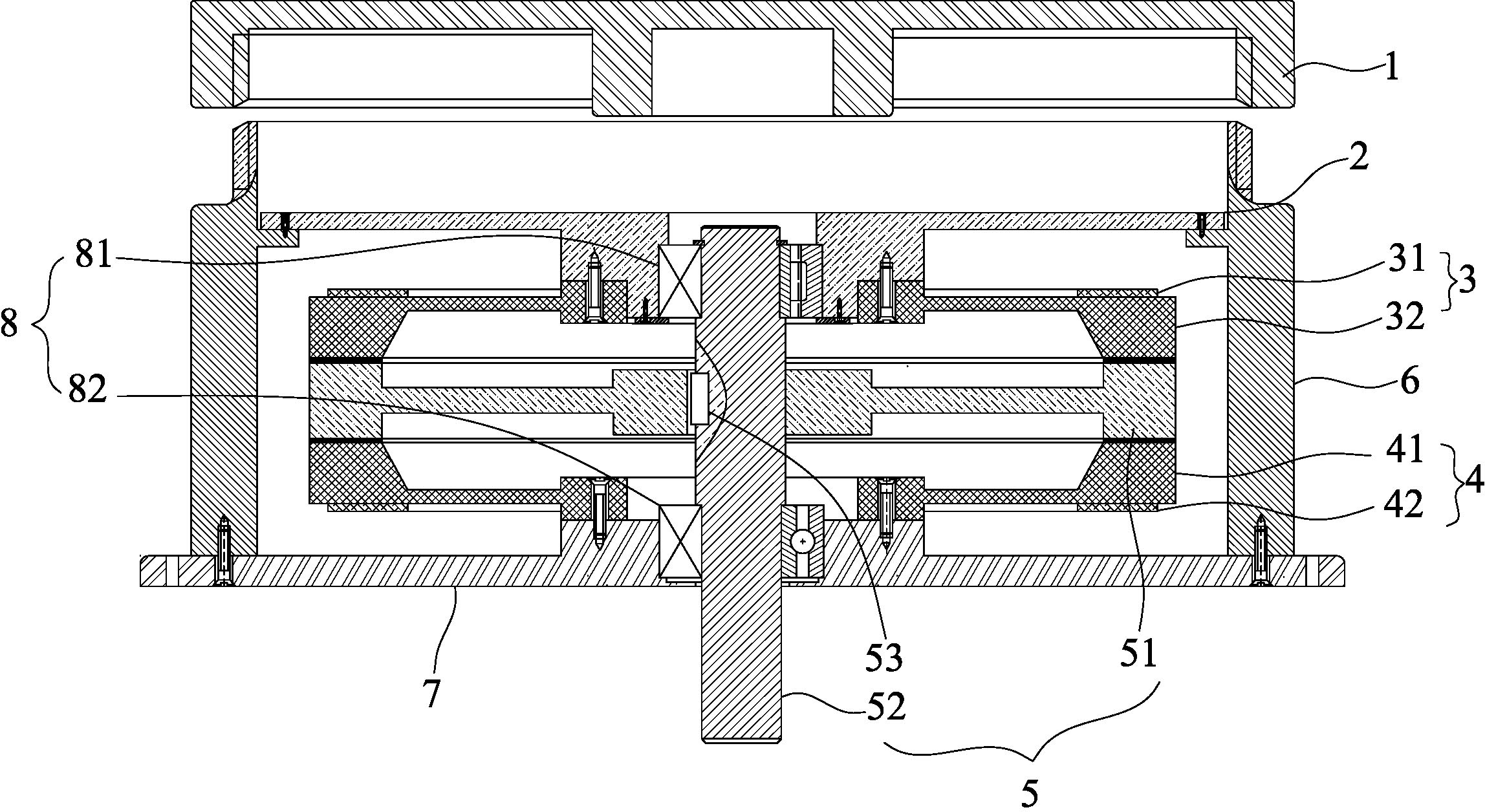

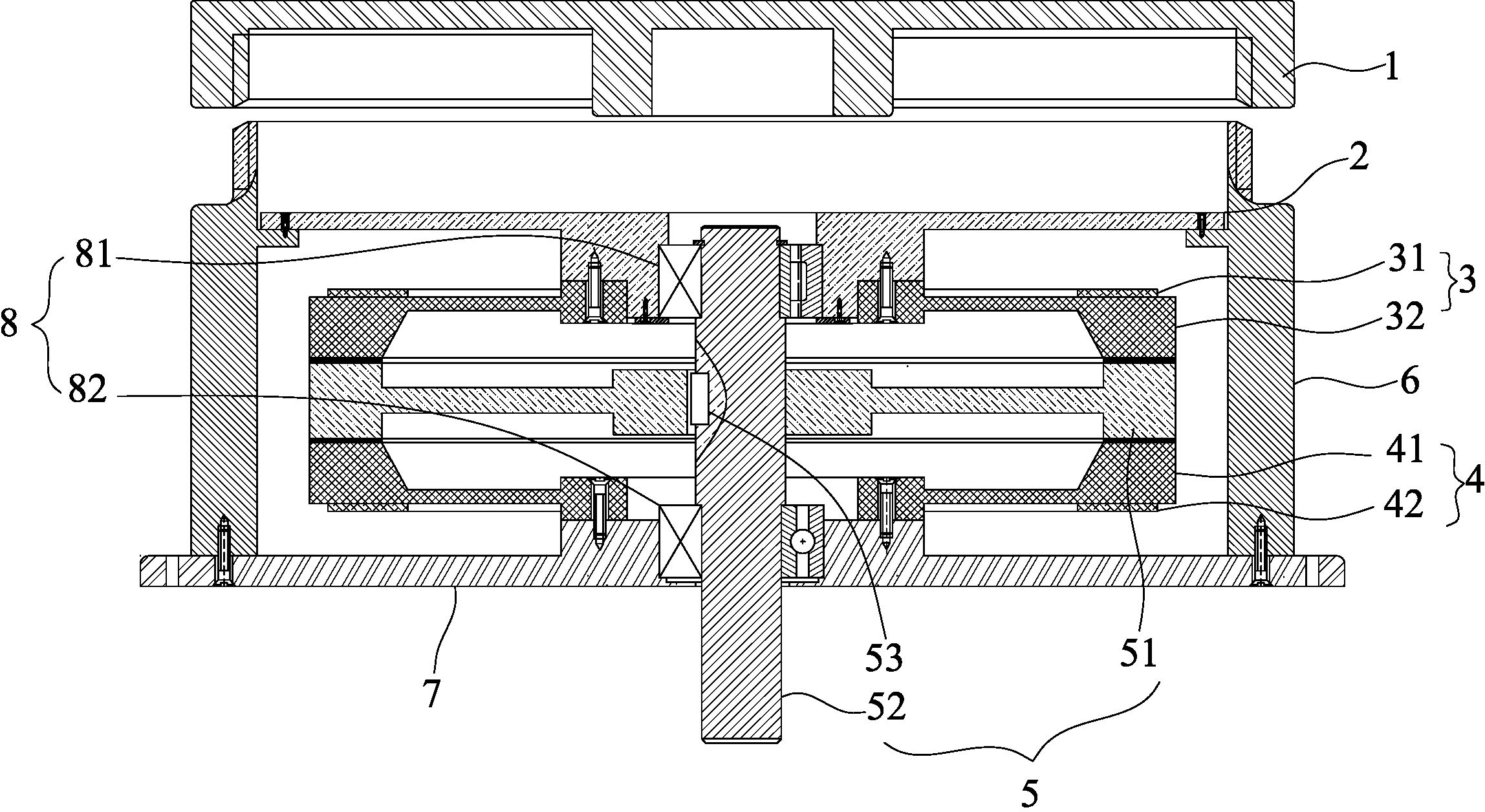

[0016] Such as figure 1 As shown, the present invention is a new rotary traveling wave ultrasonic motor, which includes an outer cover 1, a web 2, an upper stator assembly 3, a lower stator assembly 4, a rotor 5, a cylindrical shell 6, a base 7, and a bearing 8.

[0017] Described rotor 5 is made up of rotating shaft 51, rotating disc 52 and flat key 53. The center of the turntable 52 is fixedly sleeved on the rotating shaft 51 through a flat key 53 .

[0018] The outer cover 1 is threadedly connected to the top of the cylindrical casing 6, and the middle part thereof protrudes downwards. The raised platform is used to depress the web-type deformation so as to obtain a pre-pressure between the stator and the rotor. The cylindrical casing 6 The bottom is fixed on the base 7, the web 2 is sleeved on the upper part of the inner cavity of the cylindrical shell 6, and an accommodating space is formed between the web 2 and the base 7; the stator (piezoelectric vibrator) is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com