Advanced oxidization and repair method for agricultural chemically contaminated soil

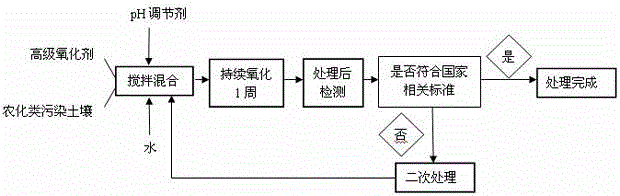

A technology of polluted soil and oxidative remediation, which is applied in the restoration of polluted soil, etc., can solve the problems of reduced oxidation efficiency, affected soil performance, and inability to carry out secondary use, so as to avoid excessive acidification and ensure high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

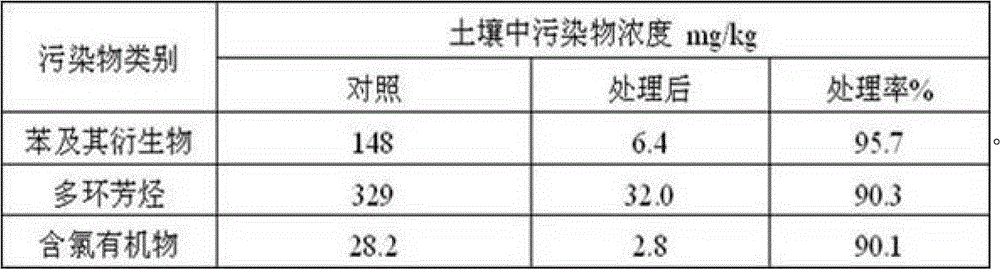

[0024] At room temperature, prepare the oxidant according to the ratio of 43% potassium persulfate, 25% potassium bisulfate, 30% potassium sulfate, 1% sodium bisulfate, and 1% sodium sulfate, and then mix it with agrochemical organic polluted soil at a ratio of 1:2000 Mix, then add 10% by weight of water and 0.05 of the pH regulator for conditioning, the composition by weight percentage is: calcium peroxide is 10%, calcium oxide is 30%, silicon oxide is 30%, orthophosphoric acid The salt content was 30%. After fully stirring and mixing, the pH of the soil sample was measured to be 7.8. Stacked outdoors at room temperature for 1 week, and covered the surface of the treated soil samples with ordinary light-shielding and water-proof materials to prevent the impact of rainwater seepage or sunlight on the reaction. After treatment, the concentration of pollutants in the soil before and after treatment was analyzed according to the US EPA 8270D method. The analysis results showed th...

Embodiment 2

[0026] At room temperature, prepare the oxidant according to the ratio of potassium persulfate 50%, potassium bisulfate 26%, potassium sulfate 22%, sodium bisulfate 1%, and sodium sulfate 1%, and then mix it with agrochemical organic pollution at a ratio of 1:5000 Mix, then add 10% by weight of water and 0.1 pH regulator for conditioning, the composition by weight percentage is: calcium peroxide is 5%, calcium oxide is 25%, silicon oxide is 40%, orthophosphate After fully stirring and mixing, the pH of the soil sample was measured to be 7.2. Stacked outdoors at room temperature for 1 week, and covered the surface of the treated soil samples with ordinary light-shielding and water-proof materials to prevent the impact of rainwater seepage or sunlight on the reaction. After treatment, the concentration of pollutants in the soil before and after treatment was analyzed according to the US EPA 8270D method. The analysis results showed that the treatment rate of benzene and its deri...

Embodiment 3

[0028] At room temperature, prepare the oxidant according to the ratio of potassium persulfate 50%, potassium bisulfate 26%, potassium sulfate 22%, sodium bisulfate 1%, and sodium sulfate 1%, and then mix it with agrochemical organic pollution at a ratio of 1:2000. Mix, then add 10% by weight of water and 0.1 pH regulator for conditioning, the composition by weight percentage is: calcium peroxide is 10%, calcium oxide is 30%, silicon oxide is 30%, orthophosphate After fully stirring and mixing, the pH of the soil sample was measured to be 8.3. Stacked outdoors at room temperature for 1 week, and covered the surface of the treated soil samples with ordinary light-shielding and water-proof materials to prevent the impact of rainwater seepage or sunlight on the reaction. After treatment, according to the US EPA 8270D method, the concentration of pollutants in the soil before and after treatment was analyzed. The analysis results showed that the treatment rate of benzene and its d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com