Vehicle special for horizontal blue oil fitting of rudder stock

A special vehicle and rudder stock technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor quality of the rudder stock and rudder hole, unsafe high-altitude operation, and great weather influence, etc. The effect of reducing labor intensity, reducing the cost of brushing, and saving expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

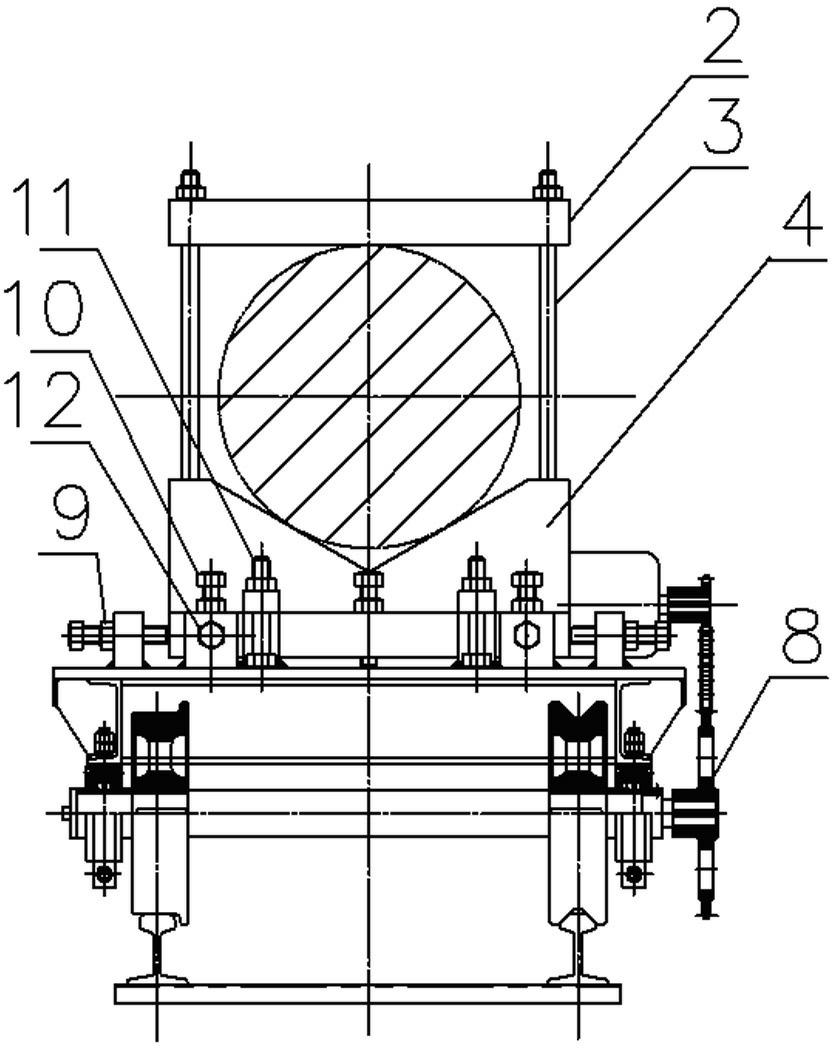

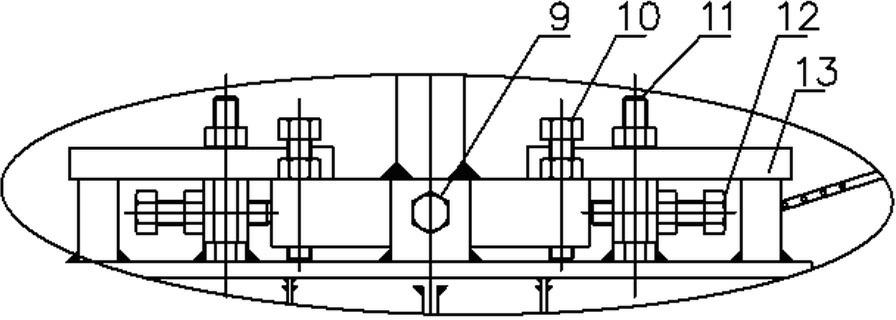

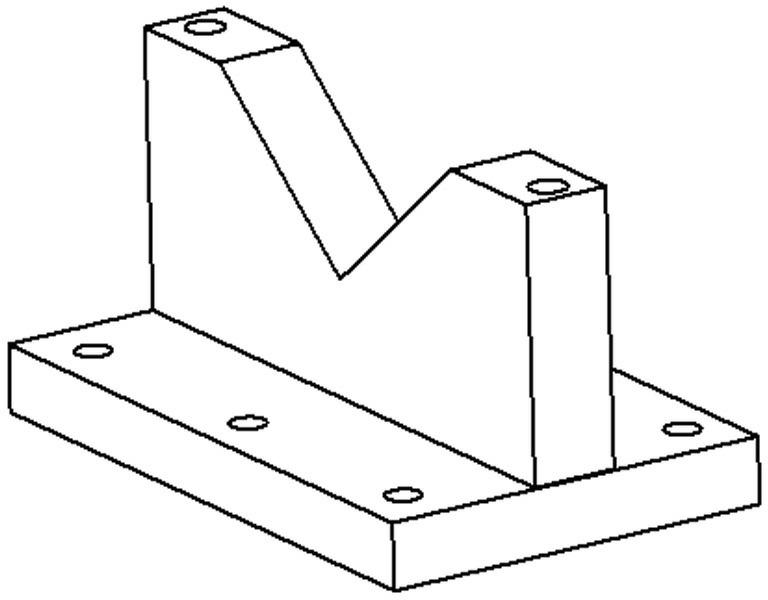

[0020] As shown in the figure, the 5000PCTC ro-ro ship rudder stock is used as an example for illustration. The horizontal rudder stock is equipped with a special vehicle, including a rudder stock 1, a cross bar 2, a screw rod 3, a V-shaped seat 4, and a free adjustment structure 5. , body assembly 6, guide rail 7 and sprocket wheel group 8, two groups of rail wheels are installed below the body assembly 6, the rail wheels are installed on the guide rail 7, and two groups of free adjustment structures 5 are installed on the body assembly 6, each group A V-shaped seat 4 is placed in the free adjustment structure 5, and the V-shaped seat 4 is located directly above the track wheel; a rudder stock 1 is placed on the V-shaped seat 4, and the track wheel is connected with the power mechanism through a chain wheel group 8 for Deliver momentum.

[0021] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com