Transverse moving device in gear machining machine

A technology of lateral movement and processing machines, applied in the field of machinery, can solve problems such as poor mechanical stability, manufacturing difficulties, bed space size, weight increase, etc., and achieve compact layout between components, improve processing accuracy, and work safely and reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

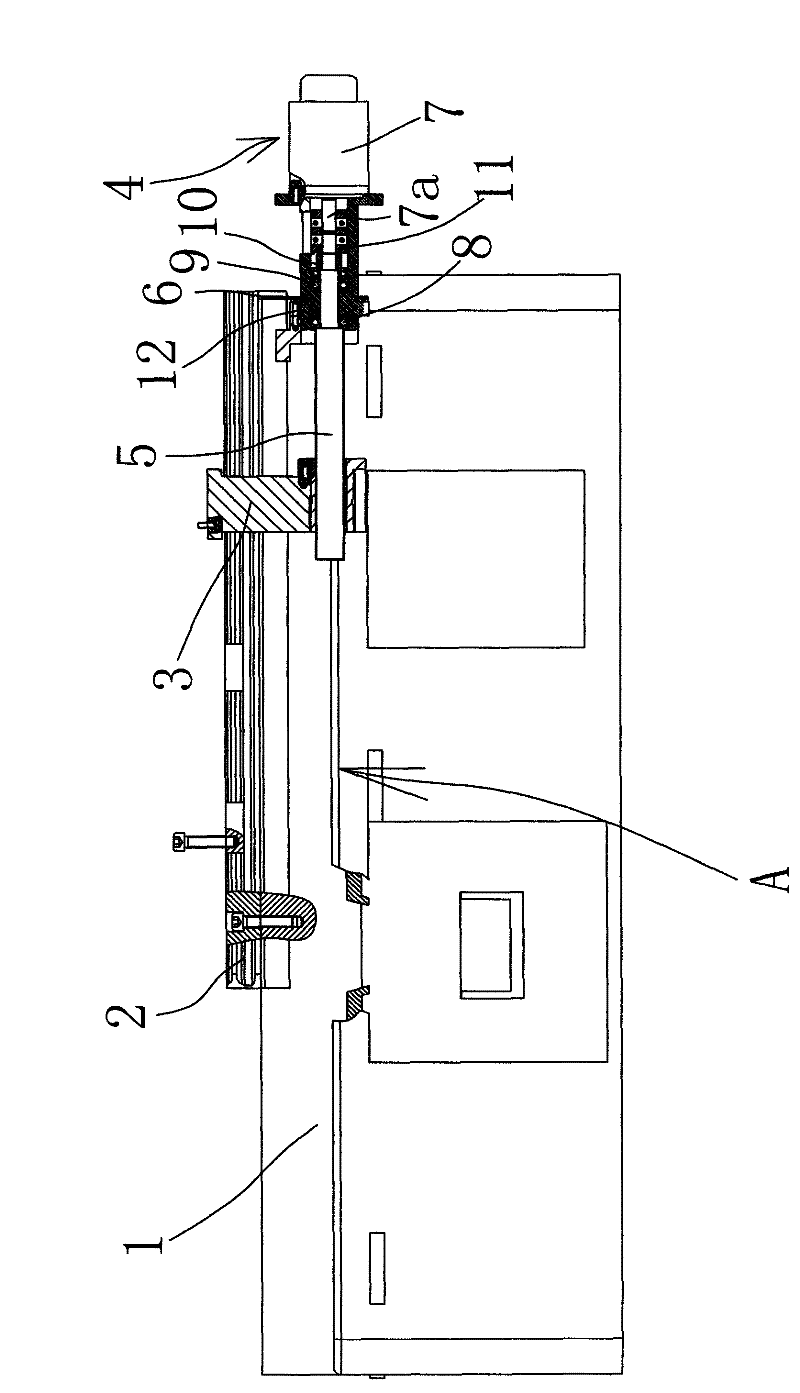

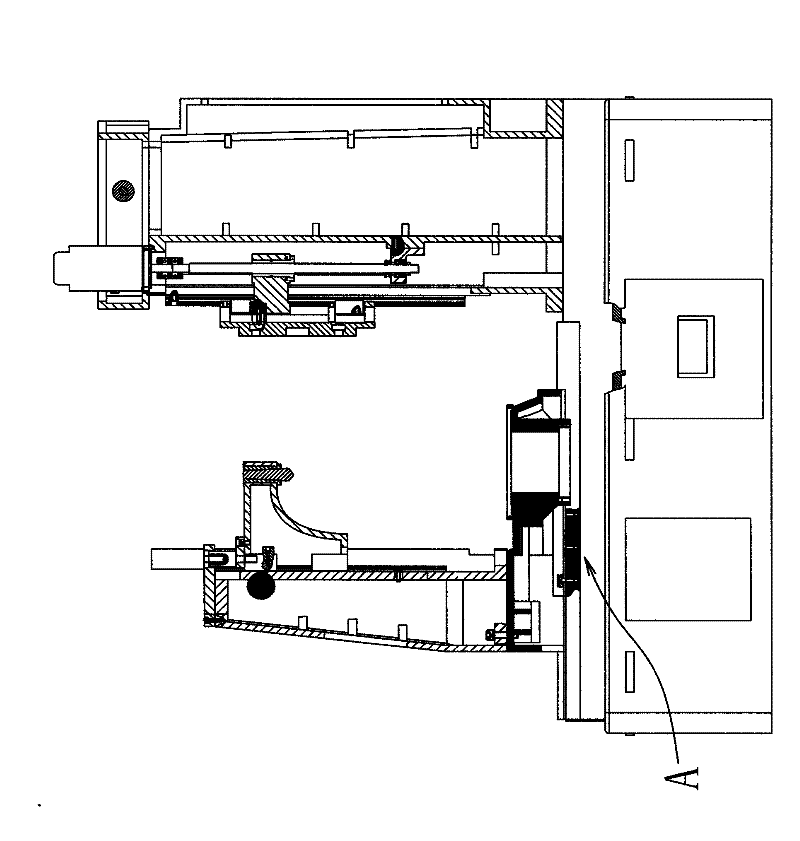

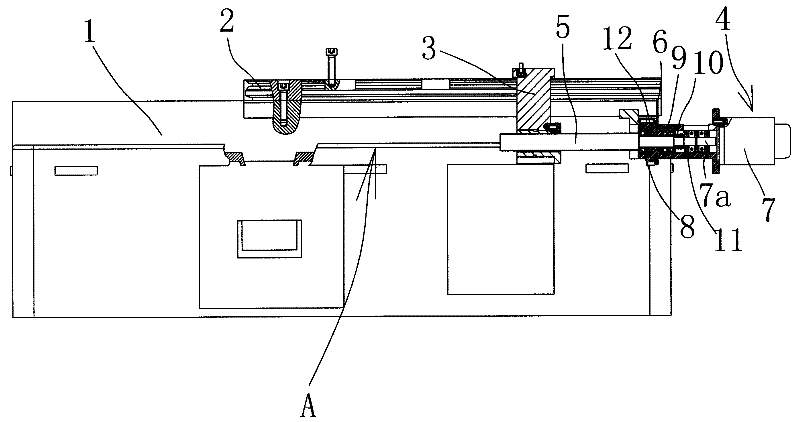

[0015] In the figure, bed 1; guide rail 2; slider 3; driving mechanism 4; screw rod 5; fixed seat 6; motor 7; output shaft 7a; plane bearing 8; deep groove ball bearing 9; lock nut 10; connecting sleeve 11; Hexagon socket head cap screw 12; Lateral movement device A.

[0016] Such as figure 1 and figure 2 As shown, the lateral moving device A in this gear processing machine is mainly used to drive the worktable to move along the X-axis direction, including a bed 1 and a driving mechanism 4, and a guide rail 2 along the X-axis direction is installed on the bed 1 .

[0017] Here the guide rail 2 is fixed on the bed 1 by hexagon socket head cap screws 12, and the bed 1 is also equipped with a slider 3 that slides along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com