Method for manufacturing electronic device shell

A technology for electronic devices and manufacturing methods, applied in the direction of coating, etc., can solve the problems of long cycle time and difficulty in controlling the degree of deformation of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the technology taught in the present invention, which does not depart from the present invention. spirit and scope.

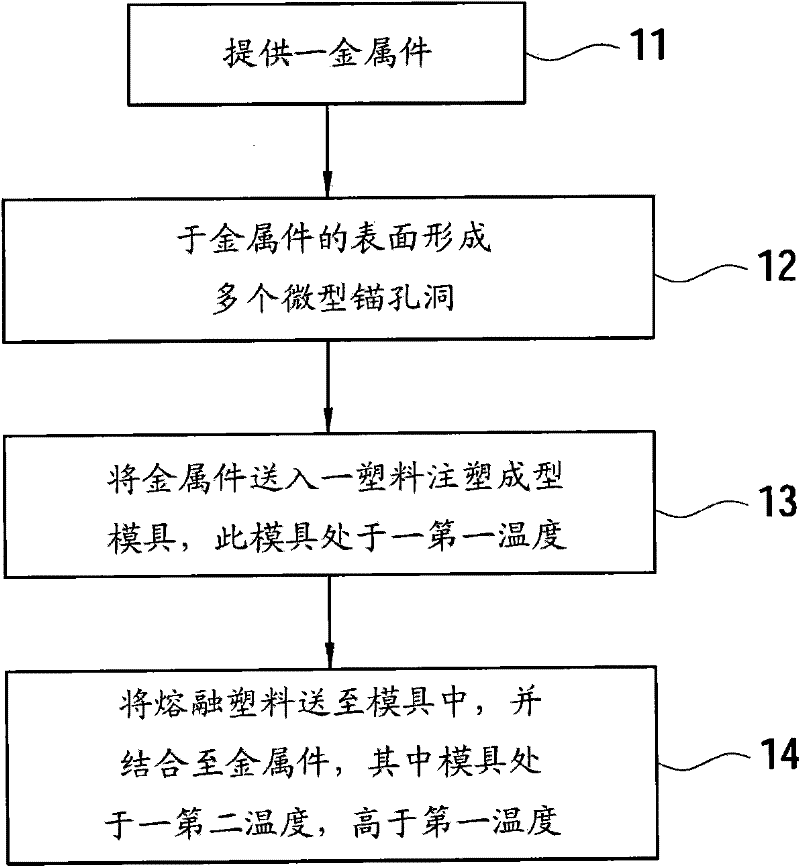

[0038] see figure 1 as shown, figure 1 A flow chart of an embodiment of the manufacturing method of the housing of the electronic device according to the present invention is shown. The manufacturing method of the electronic device housing of the present invention includes the following steps:

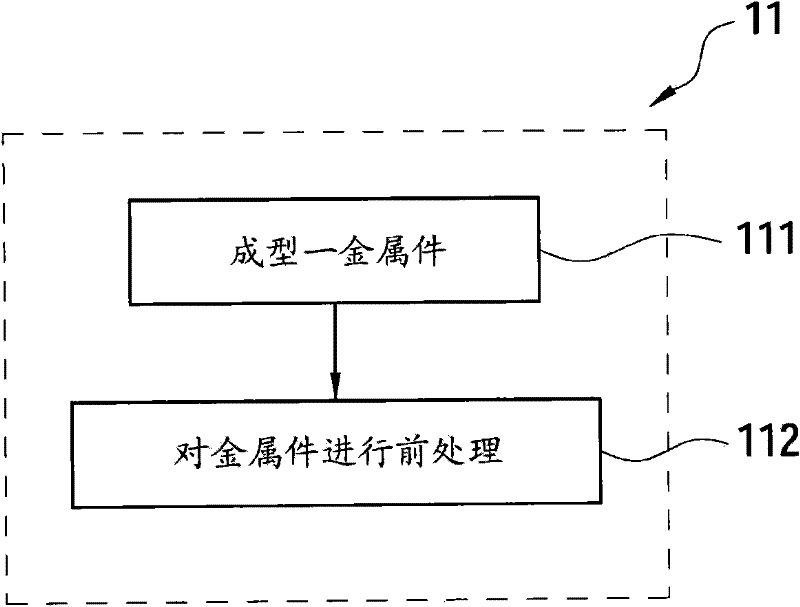

[0039] Step 11 provides a metal piece. Step 12 forms a plurality of micro-anchor holes on the surface of the metal piece. Step 13 Sending the metal part into a plastic injection molding mold, wherein the plastic injection molding mold is at a first temperature. Step 14: Sending a molten plastic to a plastic injection moldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com