Automobile body conveying device

A conveying device and vehicle body technology, which is applied to conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of inability to accurately locate the vehicle body, limited relative position of the skid, low work efficiency, etc. Safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

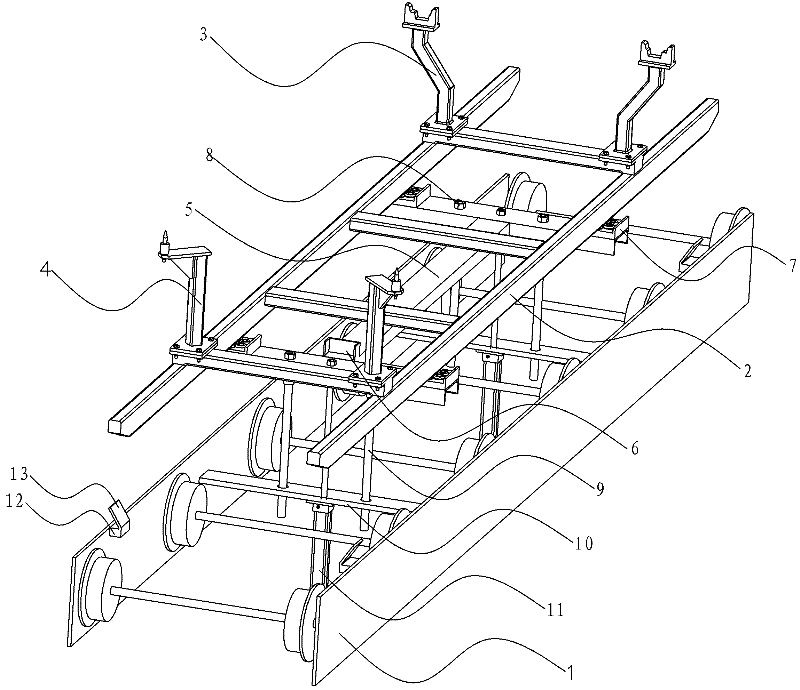

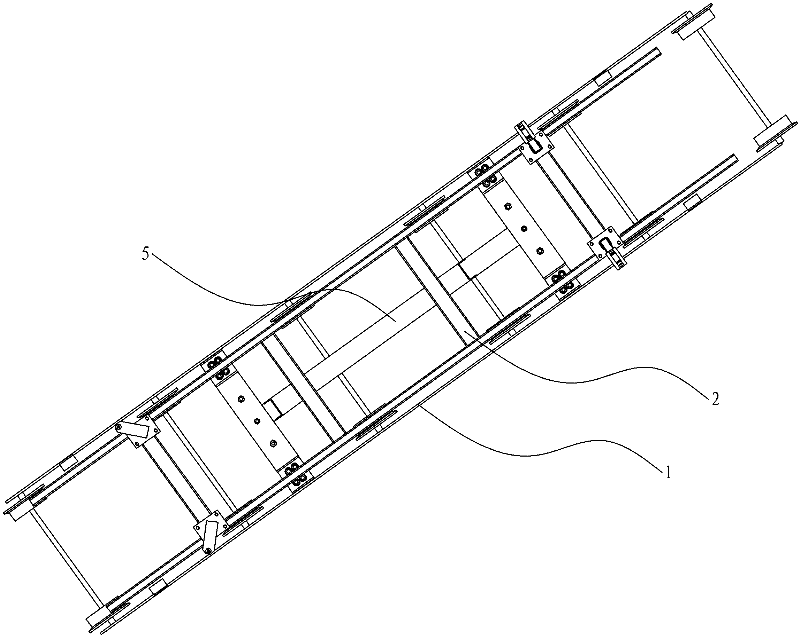

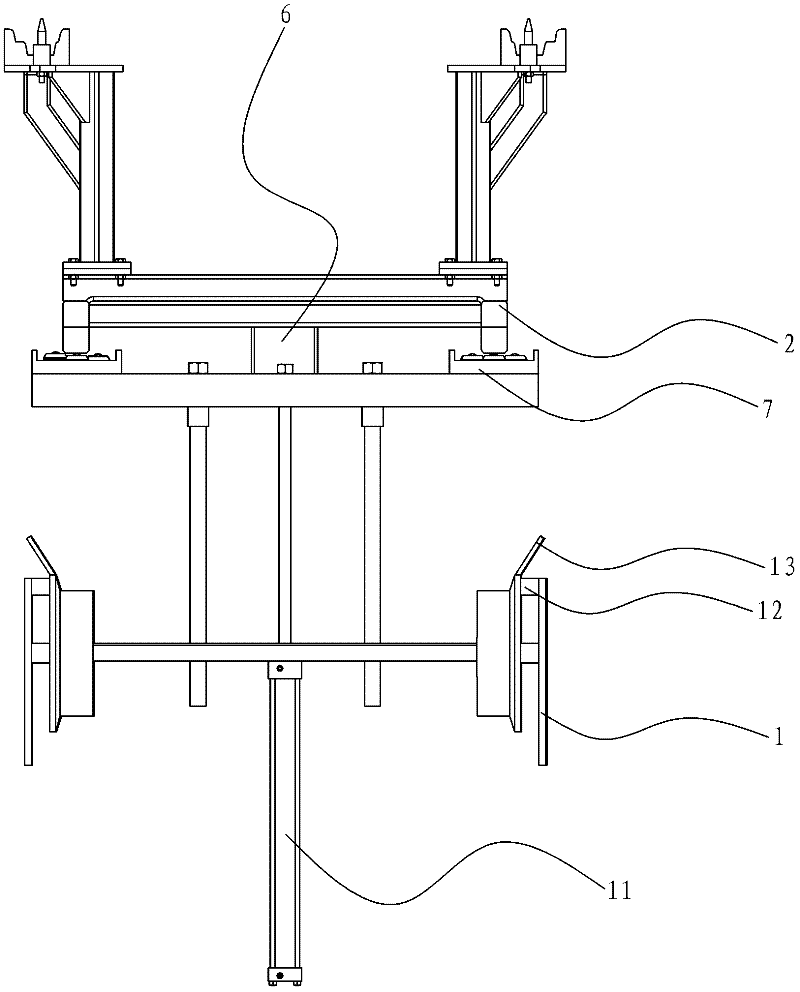

[0031] Such as figure 1 As shown, a vehicle body conveying device includes a rolling bed 1, the inner side of the rolling bed 1 is provided with a shaft-connected roller, and a skid is arranged above the roller, and the skid includes a ladder-shaped skid body 2 fixed on the skid body 2 The support assembly 3 on the upper surface of the rear end, and the positioning assembly 4 fixed on the upper surface of the front end of the skid body 2; according to the actual situation, the support assembly 3 can be designed as supports in different forms, so as to support different models The body is suitable for the mixed line production of multiple models.

[0032]The bottom of the skid body 2 is provided with a support frame 5, and two front and rear symmetrical limit blocks 6 are provided in the middle of the support frame 5 near both ends. The two limit blocks 6 are located on the support assembly 3 and the positioning assembly of the skid. Between 4, according to the actual situatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com